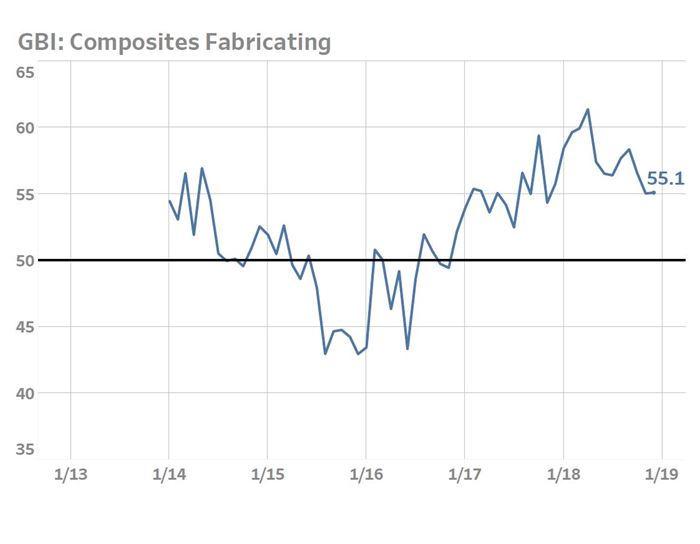

Index moves higher as five of six indicators report expansion

The GBI: Composites Fabricating Index registers a 55.1 reading for December 2018, pulled higher by supplier deliveries, production, new orders and employment.

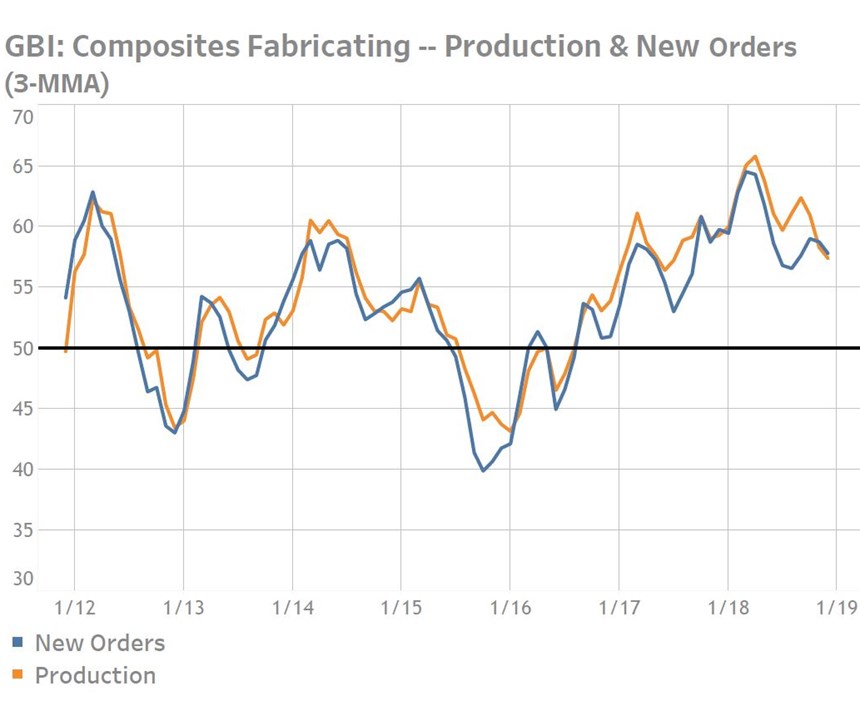

The December reading of the GBI: Composites Index of 55.1 was slightly above the prior month’s reading. Furthermore, the latest reading means that the Composites Index has now been expanding for a full two years. In comparison, the prior upcycle ended in 2014 after only eight months of continuous expansion. December’s reading also establishes 2018 as the fastest expanding calendar year since records began in late 2011. Gardner Intelligence’s review of the underlying data indicates that the Index was propelled higher during the month by supplier deliveries, production, new orders and employment. The Index — calculated as an average — was pulled lower by backlogs and exports. Exports was the only component to contract. During six of the last seven months, exports have reported contracting.

Supplier deliveries led the Index higher for a fourth consecutive month, followed by production and new orders. Stronger production growth relative to new orders and contracting exports were among the factors that potentially slowed backlog growth for a third consecutive month. Over the course of 2018, backlog growth set multiple records both in duration and magnitude. The overall strength of the industry continues to be positive as evidenced by hiring in the industry, which has expanded consistently for nearly 2.5 years. One would have to go back nearly four years to find the last instance when employment contracted in two consecutive months.

Related Content

-

Materials & Processes: Composites fibers and resins

Compared to legacy materials like steel, aluminum, iron and titanium, composites are still coming of age, and only just now are being better understood by design and manufacturing engineers. However, composites’ physical properties — combined with unbeatable light weight — make them undeniably attractive.

-

Plant tour: Joby Aviation, Marina, Calif., U.S.

As the advanced air mobility market begins to take shape, market leader Joby Aviation works to industrialize composites manufacturing for its first-generation, composites-intensive, all-electric air taxi.

-

Multi-material steel/composite leaf spring targets lightweight, high-volume applications

Rassini International was challenged by Ford Motor Co. to take weight out of the F-150 pickup truck. Rassini responded with a multi-material steel/composite hybrid leaf spring system that can be manufactured at high volumes.

.jpg;width=70;height=70;mode=crop)