ACPT’s carbon fiber composite driveshafts are used in a range of industries. Photo credit, all images: Roth Composite Machinery

For years, composites fabricator Advanced Composites Products & Technology Inc. (ACPT, Huntington Beach, Calif., U.S.) has worked diligently to develop and perfect its design for carbon fiber composite driveshafts — carbon fiber composite or metal tubes connecting the front and rear parts of the drivetrain underneath most vehicles. Though first used in the automotive sector, these versatile components are also widely used for marine, commercial, wind, defense, aerospace and industrial applications, and ACPT has seen the demand for carbon fiber composite driveshafts grow steadily over the years. As demand has continued to increase, ACPT recognized a need to manufacture larger quantities of driveshafts — hundreds of the same shaft per week — with greater manufacturing efficiency, leading to new innovations in automation, and ultimately a new facility.

The reason for increased driveshaft demand, ACPT says, is due to carbon fiber driveshafts’ unique blend of capabilities compared to their metallic counterparts, such as higher torque capacity, higher RPM capability, better reliability, lighter weight, increased safety due to an inclination to break down into relatively harmless carbon fibers upon high impact and reduced noise, vibration and harshness (NVH).

In addition, compared to conventional steel driveshafts, carbon fiber driveshafts in cars and trucks are reported to increase a vehicle’s rear-wheel horsepower by more than 5%, due primarily to the composite having a lighter rotational mass. A lightweight carbon fiber driveshaft absorbs more shock and has a higher torque capacity than steel, allowing more engine power to be transferred to the wheels without the tires spinning out or separating from the pavement.

For years, ACPT has produced its carbon fiber composite drive shafts via filament winding at its California facility. To scale up to the required levels would required increasing facility size, improving production equipment and streamlining process control and quality inspection by shifting responsibility as much as possible from human technicians to an automated process. To achieve these goals, ACPT decided to build a second production facility, and to equip it with higher levels of automation.

ACPT Driveshafts

ACPT located this new production facility in Schofield, Wis., U.S., to minimize disruption in driveshaft production during the 1.5-year process of designing, building, procuring and installing the new plant and production equipment, with 10 months dedicated to construction, delivery and installation of an automated filament winding system.

Each step of the process for producing a composite driveshaft was evaluated for automation: filament winding, resin content and wetout control, oven cure (including time and temperature controls), part extraction from the mandrel and handling of mandrels to and from each step of the process. An overhead or floor-mounted gantry automation system, however, was rejected as an option, both for budgetary reasons and ACPT’s need for a less permanent, moveable system to allow for limited-quantity R&D trials when necessary.

Two-part, semi-automated production system

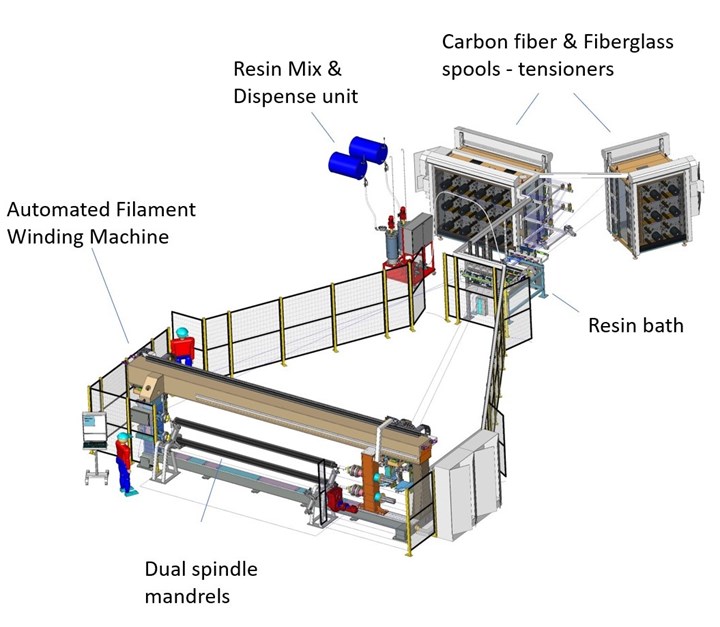

After consulting with several suppliers, the resulting solution is a two-part production system: a Type 1, two-spindle automated filament winding system with multiple winding carriages from Roth Composite Machinery (Steffenburg, Germany); and, rather than an immobile mounted automation system, a semi-automated mandrel handling system designed by Globe Machine Manufacturing Co. (Tacoma, Wash., U.S.).

An illustration of the automated filament winding process that Roth developed for ACPT.

ACPT says one of the main advantages and requirements of the Roth filament winding system, which is designed to allow two spindles to simultaneously produce parts, was its proven automation capabilities. This was especially important given that ACPT’s proprietary driveshafts require multiple material changes. To automate manual cutting, stringing and reattaching of different fibers for each material change, Roth’s roving cut and attach (RCA) feature enables the winding machine to automatically change materials with its multiple manufacturing carriages. The Roth resin bath and fiber tensioning techniques also provided the ability to ensure precise fiber to resin wetout ratios without oversaturation, enabling the winding machine to operate faster than conventional winders without excess resin waste. Once winding is complete, the winder automatically disconnects the mandrel and part from the winding machine.

Roth’s filament winding system automatically switches between composite materials.

The winding system itself is automated, but that still leaves a large portion of handling and movement of mandrels between each manufacturing step, each of which was previously done manually. This includes preparing bare mandrels and attaching them to the winder, moving mandrels with wound parts to the oven for cure, moving mandrels with cured parts and extracting parts from the mandrel. As a solution, Globe Machine Manufacturing Co. developed a process involving a family of carts designed to accommodate mandrels that sit on the cart. A rotation system within the cart serves to position the mandrels for transfer in and out of the winder and extractor and to rotate continuously while parts are wet with resin and during oven cure.

These mandrel carts move from station to station, aided by two sets of floor-mounted transfer arms — one set at the winder and one set at an integrated extractor system — that coordinate motion with the mandrel carts, and pick-and-place mandrels for each process. Custom chucks on the carts automatically clamp and release the mandrels, which coordinate with the automated chucks on the Roth machine.

Roth two-spindle precision resin bath assembly. The system is designed for two spindles of composite materials and delivery to dedicated material winding carriages.

Along with this mandrel transfer system, Globe also provided two curing ovens. After cure and mandrel extraction, parts are transferred to a precision-length cutter and then a CNC system for machining of tube ends, followed by cleaning and application of adhesive with pressed fitting attachments. Torque tests, quality assurance and product tracking are completed prior to packing and shipping for the end-use customer.

One important aspect of the process, according to ACPT, is that it is able to track and log data such as facility temperatures, humidity levels, fiber tensions, fiber speeds and resin temperatures for each winding set. The information is stored for use in product quality inspection systems or production tracking and can enable the operator to make adjustments to the production conditions if necessary.

The overall process developed by Globe is described as “semi-automated” because human operators are still needed to press buttons to initiate process sequences, and to manually move the carts into and out of the ovens. According to ACPT, Globe envisions an even higher degree of automation for this system in the future.

The Roth system includes two spindles and three separate winding carriages. Each winding carriage is designed for the delivery of different composite materials automatically. Composite materials are applied simultaneously to both spindles.

After the first year of production at the new facility, ACPT reports that the equipment has successfully demonstrated the ability to meet its volume goals while providing labor and material savings and a consistently high-quality product. The company hopes to work with Globe and Roth again for future automation projects.

For further information, please reach out to Ryan Clampitt, president of ACPT (rclamptt@acpt.com), Joseph Jansen, national sales manager at Roth Composite Machinery (joej@roth-usa.com) or Jim Martin, director of advanced composite equipment at Globe Machine Manufacturing Co. (JimM@globemachine.com).

Related Content

Carbon fiber in pressure vessels for hydrogen

The emerging H2 economy drives tank development for aircraft, ships and gas transport.

Read MoreSulapac introduces Sulapac Flow 1.7 to replace PLA, ABS and PP in FDM, FGF

Available as filament and granules for extrusion, new wood composite matches properties yet is compostable, eliminates microplastics and reduces carbon footprint.

Read MoreMaterials & Processes: Fabrication methods

There are numerous methods for fabricating composite components. Selection of a method for a particular part, therefore, will depend on the materials, the part design and end-use or application. Here's a guide to selection.

Read MorePEEK vs. PEKK vs. PAEK and continuous compression molding

Suppliers of thermoplastics and carbon fiber chime in regarding PEEK vs. PEKK, and now PAEK, as well as in-situ consolidation — the supply chain for thermoplastic tape composites continues to evolve.

Read MoreRead Next

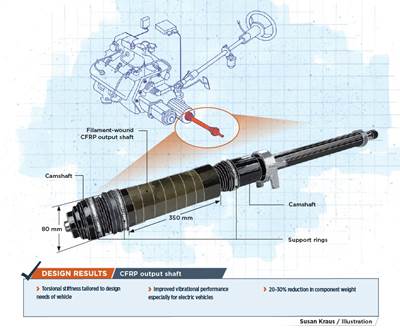

Composite output shaft ready for automotive proving ground

Unlike automotive driveshafts, automotive output shafts cannot leverage shaft length as a factor when making the case for composites. Instead, other beneficial features have made a composite output shaft able to compete with metal shafts, especially in electric vehicles.

Read MoreLow-profile, high-performance manufacturer

Advanced Composite Products & Technology Inc. provides innovative and cost-efficient composite solutions to some of the most difficult and demanding real world applications.

Read MoreCharger Investment Partners acquires Advanced Composite Products and Technology, Inc.

Partnering with Charger will further accelerate ACPT’s leadership position in the composites space.

Read More

.jpg;width=70;height=70;mode=crop)

.jpg;maxWidth=300;quality=90)