Vibration-canceling composite technology

Materials Sciences Corp.'s new product might be a solution for aircraft interiors noise and shock mitigating boat hulls?

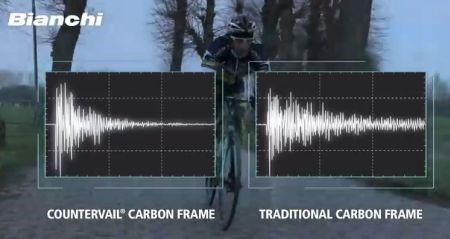

Materials Sciences Corp.'s COUNTERVAIL composite material helps cancel vibrations in the Infinito CV high-performance racing bicycle. SOURCE: Bianchi.

Materials Sciences Corp. (MSC, Horsham, Penn., USA) has provided design, analysis, engineering and testing services to the advanced composites industry since 1970. It has worked with the U.S. Army, Navy, Air Force, NASA, and DARPA as well as renowned industry leaders such as Seemann Composites Inc. and McDonnell Douglas (now Boeing) Phantom Works. Its projects span a huge range of topics including multifunctional composites, damage tolerance, fire performance, armor systems, nanocomposites and design allowables methodologies, to name just a few.

One of its latest developments is a low acoustical insertion loss composite for sonar windows using MSC’s proprietary fiber commingling technology. The latter blends acoustical and structural fibers into a tailored fabric and multilayer composite which enables the high-strength, protective sonar dome to mimic the density and acoustical impedance of sea water through which the sonar waves travel. This then minimizes sonar wave scattering for a clearer, more accurate signal.

Now MSC — NOT to be confused with MSC Software, supplier of MSC NASTRAN plus other FEA and simulation products — is expanding its corporate mission to include transitioning its proprietary, innovative technologies from R&D into commercial products. It has already released MSC-CAN composite attachment nails for sandwich structures and LS-DYNA dynamic simulator and database which provides accurate progressive failure modeling of composite structures.

MSC has commercialized MSC-CAN (left) and LS-DYNA (right) failure modeling tool.

SOURCE: Materials Sciences Corp.

But perhaps MSC’s most ingenious product is COUNTERVAIL (globally registered trademark), which combines traditional vibration damping layer concepts with a patented fiber preform to offer “unparalleled” vibration reduction in composite structures. The preform uses a fiber pattern that maximizes the vibrational energy dissipation achieved by an integrated viscoelastic damping layer. Damping performance has been shown to be at least 200 percent better than similar constructions using traditional methods. Lay-ups can be tailored to balance vibration curbing with stiffness and strength. COUNTERVAIL’s performance does indeed look impressive in this video by bicycle manufacturer Bianchi for its new Infinito CV model:

In fact, the Infinito CV was named “Bike of the Year” by road.cc and also was used by cyclist Lars Boom to win Stage 5 of the 2014 Tour de France race, a stage known for its bike-frame chattering cobblestones.

My thoughts fast forward to the potential solution this new technology may offer for two long-time challenges involving composites: (1) Composite interior panels which are thinner, lighter yet offer reduced transmission of noise into the aircraft cabin; (2) Mitigation of repeated and severe shock loads experienced by Navy SEALs and other occupants of special warfare marine vessels due to high-speed wave impacts.

The latter has caused chronic and acute injuries and risks mission performance. It has also seen huge amounts of money invested into solutions which may not yet offer the performance/price point combination that this new technology could provide. Shock mitigating designs have been proposed for the hulls, decks and seats used in these boats. CW reviewed one example in the 2011 article, “Re-inventing the RHIB: Shock Mitigation”.

Meanwhile, noise transmission from air rushing past an aircraft fuselage is tricky because noise is vibration, which traditionally has been most easily addressed by adding weight — hence, the use of lead around superyacht engine rooms. Viscoelastic materials are a more modern alternative, but they too tend to be heavier than desired in aircraft and must also pass fire, smoke and toxicity (FST) regulations.

COUNTERVAIL, however, may have opened a pathway that could yet be refined to offer a solution. There are so many materials innovations affording improved flame resistance, for example University of Texas’ development of nanoclay fillers used to drop the flammability of polyurethane foam and the latest thermoplastics which offer both FST performance and higher toughness.

I’ve been invited to visit MSC’s newest facility in Greenville, South Carolina. So keep watching for our next report on Materials Sciences Corporation, COUNTERVAIL and where both are headed next.

Related Content

Plant tour: Albany Engineered Composites, Rochester, N.H., U.S.

Efficient, high-quality, well-controlled composites manufacturing at volume is the mantra for this 3D weaving specialist.

Read MoreUnderstanding vacuum bagging layers in production, repair

Recognizing the functions of each layer in a vacuum bag schedule can help users discover what vacuum bag schedules work best for their application.

Read MoreRTM, dry braided fabric enable faster, cost-effective manufacture for hydrokinetic turbine components

Switching from prepreg to RTM led to significant time and cost savings for the manufacture of fiberglass struts and complex carbon fiber composite foils that power ORPC’s RivGen systems.

Read MoreDoing the twist: A look at dimensional issues in high-temperature cured laminates

When it’s not the tooling, the root cause of dimensionally inaccurate composite parts often boils down to two things: fiber form(s) used and laminate symmetry.

Read MoreRead Next

Composites end markets: Energy (2024)

Composites are used widely in oil/gas, wind and other renewable energy applications. Despite market challenges, growth potential and innovation for composites continue.

Read MoreFrom the CW Archives: The tale of the thermoplastic cryotank

In 2006, guest columnist Bob Hartunian related the story of his efforts two decades prior, while at McDonnell Douglas, to develop a thermoplastic composite crytank for hydrogen storage. He learned a lot of lessons.

Read MoreCW’s 2024 Top Shops survey offers new approach to benchmarking

Respondents that complete the survey by April 30, 2024, have the chance to be recognized as an honoree.

Read More