CFK-Valley Stade Convention 2015 report

The composites industry in Germany is preparing for the 4th Industrial Revolution.

Previous CFK-Valley Stade technical conferences have lacked nothing in the way of excellence. Papers have unfailingly revealed the latest technology from academic institutions and reported the most forward-looking automated production techniques from German industry. But two new features made the 2015 event stand apart. The first was the new concept of Partner Countries. This year’s partner was Belgium, with a surprise benefit that I will come to later. The second was announced in the conference title: “Industry 4.0 for Composites.” New to many in the audience, particularly those outside Germany, the term “Industry 4.0” was coined in 2011 and refers to the integration of the supply chain based on three concepts: cyber-physical systems, the Internet of Things and the Internet of Services, a combination which is expected to lead to what proponents call truly “Smart Industries.”

Opening day

CFK-Valley Stade CEO Gunnar Merz opened proceedings by introducing Industry 4.0 — shorthand for the Fourth Industrial Revolution, the follow-on to the first, based on the steam engine; the second, on the use of electrical systems to power Ford’s assembly lines; and the third, powered by today’s computer-controlled machines and local networking. Merz’s description, however, went beyond the concept of a smart factory to include all interfacing organizations in a Smart Complex, with a target date of 2040.

After Merz set the conference theme in perspective, two keynote speakers took turns at the podium.

The first, Eva Brockhous of ptJ (Jűlich, Germany), addressed the all-important subject of funding for R&D. In Europe, the European Union’s (EU) Framework series of programs will finish with the currently ongoing 7th Framework and will be replaced by Horizon 2020. To encourage participation, the German government was enabling companies to obtain advice from ptJ, free of charge. There were strict rules for how teams of companies could be formed to be eligible for funding. The minimum requirement was a team of three legal entities from three EU member states.

The second keynoter, Prof. Berend Denkena, head of IFW at Leibniz Universität Hannover (Hanover, Germany), picked up the Industry 4.0 theme. Denkena explained that what began as a German concept is gaining recognition globally and, although some details aren’t yet defined, 4.0 involves a cloud-based system that could enable an entire industrial complex to communicate via smart devices: A smart machine tool, for example, might measure excessive deflection of a cutter, draw a conclusion as to the cause, then take corrective action, which might include placing the order for a replacement cutter from the supplier.

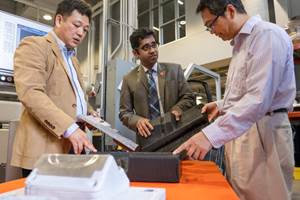

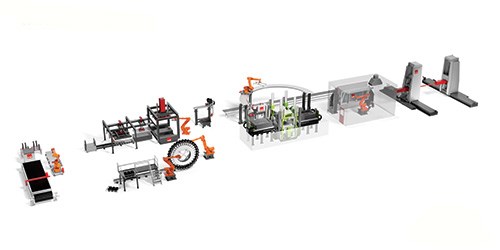

Wilhelm Rupertsberger, of Fill Gesellschaft mbH (Gurten, Austria), gave a wide-ranging presentation on Fill’s automated production systems. Examples were given of its applications in the automotive and aerospace industries (see Fig. 1, above). Also shown were a wide range of NDT cells, many including robots. Further, integrated and automatic data handling systems were shown to provide high-quality data to ensure transparent, highly efficient machine operations.

Dr. Nikos Pantelelis, of Synthesites UK Ltd. (Piraeus, Greece), reported that an intelligent monitoring system has been developed for the monitoring of composites curing, providing real-time Tg indication. A module has been added that also checks the degree of cure in real time by means of measurements of the electrical resistance and temperatures. This module is specific for each type of resin.

Dr. Carsten Schmidt, an engineering researcher at the University of Hannover + IFW (Stade), has redesigned the design process so that manufacturing planners are involved earlier and detailed design happens later. He outlined an innovative design for a fuselage panel that was fulfilled by this process, which yielded a 2.3% lighter panel with bigger windows and increased manufacturability. The double-curvature of the new design produced a few quality issues for the automated fiber placement (AFP) machine, such as gaps between placed tows, but work was undertaken to show that this was predictable and within acceptable tolerances.

Dr. Yves-Simon Gloy, head of the Textile Machinery/Production Technologies division at RWTH Aachen University, ITA (Aachen, Germany) returned to the conference theme, raising the question in his presentation title, “Will Industry 4.0 bring an evolution or a [R]evolution to automating composites?” He provided many examples where networked data were used to automate both textile machines and composite processing. His conclusion was that it would, indeed, bring a revolution to the composites industry.

In his interesting and detailed review of current carbon fiber manufacturing capacities, costs and methods, Dr. Henry Shin, head of the ICC lab at the Korea Institute of Carbon Convergence Technology (KCTECH, Jeonju, Republic of Korea), showed that the precursor contributes more than half of fiber cost and that, in most fiber manufacturing scenarios, it is made using a wet-spinning process, which is slow and expensive. He proposed replacing this with melt spinning. It is possible, he claimed, to exceed the Ford Motor Co. (Dearborn, MI, US) specification for T300 carbon fiber, in strength and modulus, using a precursor made by melt spinning. He was able to offer a large range of fiber diameters, from 28 to 43 μm.

Dr. Johannes Treiber, development engineer/project manager for Coriolis Composites SAS(Augsburg, Germany), presented “Automated Manufacture of Mass Production and Low-cost Materials.” The paper demonstrated how complex parts for aerospace and automotive applications can be made by AFP, followed by press forming.

Frank Wunder, Hufschmied Spanungssystem GmbH (Bobingen, Germany), talked about the high-speed cutting of carbon fiber-reinforced polymers (CFRP). The paper reviewed the current options and their weaknesses: ultrasonic-assisted drilling (high tool wear); CO2 laser and waterjet (both high-cost systems). The recommended solution was ultra high-speed machining at 60,000 rpm, with examples of what could be done with such a high-speed system.

Darmstadt-based Evonik Corporation marketing expert Uwe Lang announced two solutions that address a previous processing weakness for the company’s ROHACELL foam: the need to machine or very slowly thermoform the foam to simple shapes. The latter process involves a preheating period of nearly an hour due to the foam’s excellent insulation properties. Lang says a new way has been found to heat the foam by using a selected infrared frequency, which penetrates the material, reducing heat-up times to a few minutes, as the first stage for what has been renamed a “thermoshaping” process, called the In Mould Forming (IMF) method. Secondly, Evonik has a new version of ROHACELL, named Triple F, that can be molded into complex shapes see Fig. 2, below).

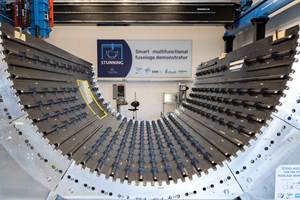

Dr. Felix Kruse, head of the Department of Composite Process Technology at the Institute of Composite Structures and Adaptive Systems, German Aerospace Center (DLR) at Stade, explained how he has developed a machine that lays dry tows in a wide band through a laying head. Judging from the slides shown, the positioning of the tows was so precise that the band of material deposited looked more like a wide tape of UD prepreg. It was reported that the fibers were dry and had no binder. The process, Automated Direct Fiber Placement, was developed to enable a new design for wind turbine blades.

Belgium’s keynoter, Julie Leroy, introduced the two Belgium organizations that will be involved with CFK. First is AGORIA (Brussels), for which she is business group leader. AGORIA brings together members from the technology sector, most of whom are involved with composites. Second is Brussels-based sirris, a collective that connects clients with testing, consulting and technology marketing expertise. The concepts of Industry 4.0, she noted, have been taken up by Belgian industry, under the banner, “Made Different.”

Dr. Eli Voet introduced work on composite structures with sensors embedded in or on the laminate. His company, Com&Sens (Zwijnaarde, Belgium), of which he is a managing associate, applies Fiber Bragg Gratings in a variety of applications, such as marine turbines. Beyond the obvious operational uses, measuring in-service strains on structures, examples were given of additional use in monitoring production processes, such as filament winding and thermoplastic tape laying.

Day two

The second day began a keynote from Hermann Rosen, founder of the Rosen Group (Karlsruhe, Germany), about the use of an integrated system to run a truly global company. Although the company at issue was in the service side of the oil industry, it was a good vision of where the composite industry needs to aim.

Marcus Kleinberg, from the DLR portal at Braunschweig, showed a new approach to composite molding process control. Applicable equally to open and closed mold processes, his premise was based on the fact that raw materials and production processes have tolerances that are in the production specification. Today, the typical way of solving this problem is defining a conservative, and invariable, production corridor. His proposal is to use sensors, typically of the ultrasonic type, to monitor the ongoing processes and to adjust production parameters during the process — or at least correct the parameter settings for the next shot. He believes this will improve repeatability and perhaps reduce production cycle times and scrap rates.

Dr. Christian Weimer, head of operations at Airbus Group Innovations (Stade), reported on a program to auto-mate the inspection of laminates laid by AFP machines in parallel with the layup process. Program targets are ambitious: Reduce inspection times by 95%, nonconformities by 50% and total inspection time, including NDT, by 50%.

Dr. Fabian Schreiber, a board member at ark industrie AG in Aachen, showed how many elements necessary for implementing Industry 4.0 in the composite industry are available today. These range from ways of communicating with operators (Google Glass) to the use of the cloud. Textile machines, such as braiders, could incorporate RFID chips in each bobbin, to control material supply, and stress sensors in each braided structure for health monitoring, allowing the safe use of lighter structures.

Alexander Schönberg, FFT Produktionssysteme GmbH & Co. (Fulda-Rodges, Germany), described a system FFT developed to locate the stringers on the Airbus A350 wingskins. A circumferential and longitudinal tolerance of about ±1 mm after curing is required. Therefore, the stringers must be positioned by robots with 0.3 mm accuracy. The end-effector is moved by four robots located on each side of the tool. The accuracy requires that the position is checked by laser trackers that send signals to the robots together with data from a force sensor. The FTT technology is called absolute robot positioning (Ab.Ro.Pos) and uses an Emscon-client to manage laser trackers (Leica AT901-XR with a T-Mac) and an ATI Omega 160 force/torque sensor on each of the end-effectors.

Dr. John Klintworth, director of strategy at Dassault Systèmes (Woking, UK), wrapped up the conference by uniting the convention’s composites and Industry 4.0 themes. He talked about using a single data model that could transform the efficiency of using composites by modeling and simulating all the processes, from design through to manufacturing. What was new was the plan to include an integrated cost model in the system, so that designers could quickly compare the cost of different options.

Welcome change

We live in a time when the overall manufacturing industry is about to go through one of its occasional “revolutions.” The composites industry will not be exempt. In fact, the complexity of the products made from composites and the associated intricacies of composite designs indicate that our industry will have the most to gain. So let us all welcome the changes that are approaching!

Institute of Plastics Processing (IKV) at RWTH Aachen University

Related Content

German UniFix project develops mobile holding fixture to enhance production efficiency of large CFRP structures

Fraunhofer IFAM and Airbus Operations in Stade demonstrate reduced manual handling and non-productive time in flow-oriented manufacturing of vertical tail plane.

Read MoreClemson Composites Center leads research in low-cost composite tooling

Innovative technology approach to use additive manufacturing and artificial intelligence to produce tools faster, at a lower cost and with less environmental impact.

Read MoreThermoplastic composites welding: Process control, certification, crack arresters and surface prep

More widespread use of welded composite structures within a decade? Yes, but further developments are needed.

Read MoreFiberglass Cutting Operation at Hubbell’s Lenoir City Plant Moves to Automation

Automating fabric cutting operations saves Hubbell Lenoir City money and can produce composite products faster at less cost to support infrastructure expansion.

Read MoreRead Next

CW’s 2024 Top Shops survey offers new approach to benchmarking

Respondents that complete the survey by April 30, 2024, have the chance to be recognized as an honoree.

Read MoreComposites end markets: Energy (2024)

Composites are used widely in oil/gas, wind and other renewable energy applications. Despite market challenges, growth potential and innovation for composites continue.

Read MoreFrom the CW Archives: The tale of the thermoplastic cryotank

In 2006, guest columnist Bob Hartunian related the story of his efforts two decades prior, while at McDonnell Douglas, to develop a thermoplastic composite crytank for hydrogen storage. He learned a lot of lessons.

Read More

.jpg;maxWidth=300;quality=90)