Graphene edges closer to widespread production and application

New process may open door for mass production of high-quality nanomaterial targeted to replace copper mesh on composite aircraft.

According to a Graphene Council presentation (slide 12), it would take an elephant balanced on a pencil to break through a sheet of graphene the thickness of cling film. Its development is being targeted for a wide range of composites applications.

A novel process for producing single layer graphene sheets, invented by Cedar Ridge Research (CRR, New Hope, Al, US) chief scientist Larry Fullerton, has received U.S. patent 9,334,168 — the third for its free-floating graphene production technology since 2014. Leveraging the diamagnetism properties of graphene, it synthesizes defect-free monolayer graphene and has the potential to enable volume production of high quality graphene sheets as well as tailoring to meet specific application requirements.

What is Graphene?

As explained by a Jan 2016 press release from the EU project NANOMASTER, graphene is a form of carbon in which the atoms are arranged in ultra-thin sheets just one atom thick. First isolated in 2004, its unique properties have inspired its description as “the ultimate material”.

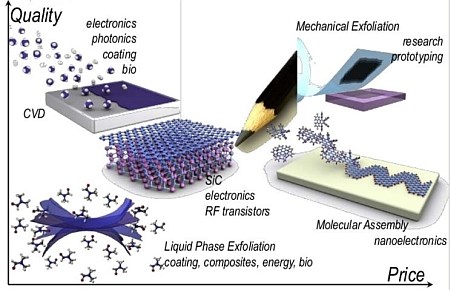

SOURCE: ResearchGate.net.

“We’ve seen some exciting properties on a lab scale but we still don’t have a large number of applications for these sorts of materials,” says Ben Hargreaves of the composites consultancy NetComposites Ltd. Hargreaves was coordinator of the EU-funded NanoMaster project, which brought together 13 partners in eight countries to explore using graphene in composites and high-volume manufacturing.

According to the University of Manchester, which dubs itself “The Home of Graphene”, graphene is:

- 200 times stronger than steel, but it is incredibly flexible.

- The thinnest material possible as well as being transparent. Ultra-light yet immensely tough.

- Ultra-light yet immensely tough.

- A superb conductor and can act as a perfect barrier - not even helium can pass through it.

Free Floating Graphene Production Process

CRR’s process for generating a floating continuous graphene film builds upon the traditional chemical vapor deposition (CVD) method. The process involves generating an even plasma distribution to produce a glow discharge of ionized carbon atoms at a desired rate that controls the continuous growth of a graphene film suspended over an alternating polarity magnetic structure. Though the latter must have a sufficient gradient to float graphene in a stable manner, the free-floating growth process requires virtually no raw materials or surface preparation and eliminates the metal etching and transfer issues that lead to efficiency-reducing atomic-scale flaws.

Graphene film produced using this free-floating process can be free of undulations, grain boundaries or defects that may cause uneven build-up of the graphene. The process also enables in-line processing of the graphene during its production to help integrate it into current manufacturing systems for semiconductors, circuit boards and composite materials.

Manufacturing high-quality graphene in high volumes has been an obstacle.

SOURCE: University of Manchester

“Our initial investigations have demonstrated an effective technique to economically produce high quality commercial scale graphene without the use of any growth substrate simply by utilizing the interplay between a magnetic field and the diamagnetic nature of graphene. This permits the growth of pristine defect-free films and alleviates the need to remove a film from a substrate after it has grown to its desired size and shape,” said Fullerton.

CRR President Mark Roberts said this pioneering patent represents “a fundamental capability to produce quality graphene sheets in a scalable and cost efficient manner that did not previously exist.” He added, “We fully expect that this technology will play a substantial role in the wide scale adoption of graphene as the next super material."

Graphene Use in Composites?

One of the first applications being developed, according to an interview published on AZoNano, is to increase the electrical conductivity of epoxy resins in the carbon fiber reinforced plastic (CFRP) fuselages of commercial aircraft in order to get rid of the need for copper mesh as lightning strike protection (LSP).

“The aircraft industry relies heavily on composite materials and lightning strikes pose a big risk as composites tend to be inert and electricity wishes to find an earth,” says Ray Gibbs, CEO of graphene producer Haydale (Ammanford, UK) — which acquired EPL Composite Solutions to become Haydale Composite Solutions (Longborough, Leicestershire, UK). “Copper mesh is currently used in the body of the aircraft,” Gibbs continues. “What we’re looking to do is reduce or remove the copper mesh by having a conductive Faraday cage around the entire aircraft. We are a way off this becoming commercially available today, but it’s potentially a highly lucrative operation.”

Other sources of recent graphene activity in composites include Oak Ridge National Laboratory and the University of Manchester. For CW articles on graphene, click here.

Related Content

Materials & Processes: Composites fibers and resins

Compared to legacy materials like steel, aluminum, iron and titanium, composites are still coming of age, and only just now are being better understood by design and manufacturing engineers. However, composites’ physical properties — combined with unbeatable light weight — make them undeniably attractive.

Read MoreComposite rebar for future infrastructure

GFRP eliminates risk of corrosion and increases durability fourfold for reinforced concrete that meets future demands as traffic, urbanization and extreme weather increase.

Read MoreMaterials & Processes: Resin matrices for composites

The matrix binds the fiber reinforcement, gives the composite component its shape and determines its surface quality. A composite matrix may be a polymer, ceramic, metal or carbon. Here’s a guide to selection.

Read MoreCarbon fiber in pressure vessels for hydrogen

The emerging H2 economy drives tank development for aircraft, ships and gas transport.

Read MoreRead Next

CW’s 2024 Top Shops survey offers new approach to benchmarking

Respondents that complete the survey by April 30, 2024, have the chance to be recognized as an honoree.

Read MoreFrom the CW Archives: The tale of the thermoplastic cryotank

In 2006, guest columnist Bob Hartunian related the story of his efforts two decades prior, while at McDonnell Douglas, to develop a thermoplastic composite crytank for hydrogen storage. He learned a lot of lessons.

Read MoreComposites end markets: Energy (2024)

Composites are used widely in oil/gas, wind and other renewable energy applications. Despite market challenges, growth potential and innovation for composites continue.

Read More