Carbon fiber-reinforced polyamide performs in engine part

When École Polytechnique de Montréal (Montreal, Canada) developed a race car to enter in the 2010 Formula SAE competition, it turned to Solid Concepts Inc. (Valencia, Calif.) and additive fabrication for help.

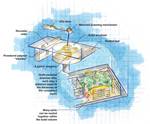

When École Polytechnique de Montréal (Montreal, Canada) developed a race car to enter in the 2010 Formula SAE (Society of Automotive Engineers, Warrendale, Pa.) competition, the school’s racing team turned to Solid Concepts Inc. (Valencia, Calif.) for help. (Solid Concepts also is mentioned in this issue's report on the recent SAMPE Tech Conference. See "Wichita welcomes SAMPE Tech," under "Editor's Picks," at right.) For their test engine, team members wanted to create a number of unique composite engine parts that, based on computational fluid mechanics (CFD) modeling, could achieve higher performance and withstand the engine environment at much reduced weight, compared to aluminum parts. Their complex shapes and relatively small sizes, however, would make conventional tooling and molding both expensive and time-consuming. But the parts were a natural fit for additive fabrication, the general process that undergirds rapid prototyping/manufacturing technologies in which a part is created directly from computer data, without tooling.

Most of the engine parts were made with Solid Concepts’ Nylon 12 GF, a glass-filled polyamide compound formulated for use in rapid manufacturing via the selective laser sintering (SLS) process. But a key engine element — the engine intake runner between the intake manifold and the engine (at upper left in photo) — was made with the company’s second-generation Nytek 1200 CF compound. It’s a proprietary trademarked SLS material in powder form: polyamide-12 polymer filled with carbon fibers that add mechanical rigidity, to withstand vibration, and enhance chemical resistance (e.g., to the fuel).

The parts were fabricated using SLS machines from EOS GmbH (Munich, Germany) and 3D Systems Corporation (Rock Hill, S.C.) in which the powdered Nytek was heated and then built up in successively fused layers. High-power laser energy was directed via a two-mirror galvanometer to the powder bed, heating and fusing the layers in a pattern dictated by the part’s CAD design data, says Frederick Claus, Solid Concepts’ business development manager (for more SLS process specifics, see endnote). Finished air intakes met weight and performance targets, including service at temperatures of ~140°F/60°C, without air leakage. “We gained 15 percent in air mass flow through the intake parts due to the precise part shapes that are possible using SLS, as well as significant gain in engine power and torque,” says engine team manager Alexis Roussel. “SLS afforded us the freedom to explore much different designs.” (Read more about SLS in the first article listed under "Editor's Picks.")

Stratasys Direct Manufacturing

Related Content

-

Price, performance, protection: EV battery enclosures, Part 1

Composite technologies are growing in use as suppliers continue efforts to meet more demanding requirements for EV battery enclosures.

-

Materials & Processes: Fibers for composites

The structural properties of composite materials are derived primarily from the fiber reinforcement. Fiber types, their manufacture, their uses and the end-market applications in which they find most use are described.

-

Materials & Processes: Composites fibers and resins

Compared to legacy materials like steel, aluminum, iron and titanium, composites are still coming of age, and only just now are being better understood by design and manufacturing engineers. However, composites’ physical properties — combined with unbeatable light weight — make them undeniably attractive.