Reusable vacuum bagging solutions for composite applications

CAMX 2023: Smartech underscores its industrial reusable vacuum bagging products for reduced waste, easy debulking and the capability to be used for complex projects.

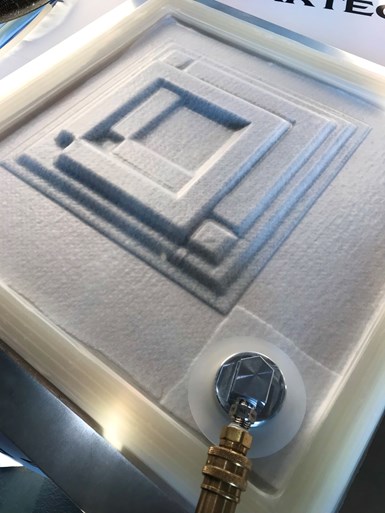

Smartech International (Charlotte, N.C., U.S.), the North America partner of Steinbach in Germany, offers industrial reusable vacuum bagging solutions that are easy to use, highly durable, long-lasting, fit to specific production needs and maximize customer performance. Customers have cited time and labor cost savings (no pleats required), reduced waste (fewer expendable materials such as sealant tape and waste products) and less skilled labor required. Increased part consistency and complexity, are additional benefits, in addition to easy debulking. An itemized lists of material and product specs can be found at Smartech’s website.

The company’s silicone bagging materials are available in a variety of durometers with smooth surfaces. Smartech’s material can be used up to 392°F and is tempered at the same temperature in a post-process to reduce outgassing, especially important for the space and aerospace industries. Vertical or horizontally oriented vacuum valve fittings provide more versatile application options.

Smartech says it takes the confidentiality and intellectual property of its clients very seriously, so the company isn’t able to list many of its projects. However, it suggests visiting its booth at CAMX or getting in touch with personnel to learn more about Smartech and how it can help with current or upcoming vacuum bagging projects.

Related Content

-

CAMX 2022 exhibit preview: Scott Bader

Scott Bader North America showcases its Crestabond and Crestomer structural adhesives, Crestafix bonding pastes, Crestapol urethane acrylate resins and Crestamould tooling systems.

-

CAMX 2022 exhibit preview compilation, Part 2

Part 2 is a continuation of some of the composites-related materials, technologies and services to be featured by CAMX 2022 exhibitors.

-

Download today's CAMX 2022 Show Daily: Tuesday, Oct. 18

Download today’s news reported live by CW on the CAMX show floor in Anaheim, California. Headlines cover this morning’s keynote, Michael Steep, Good Day, CAMX, ACE/CAMX award finalists and more.