Thermoplastic honeycomb, lightweight solar modules demonstrate sustainability

CAMX 2023: Together, EconCore and ThermHex are providing a first look at new product variations for additional lightweight opportunities, including high-performance thermoplastic cores and solar panels with a honeycomb structure.

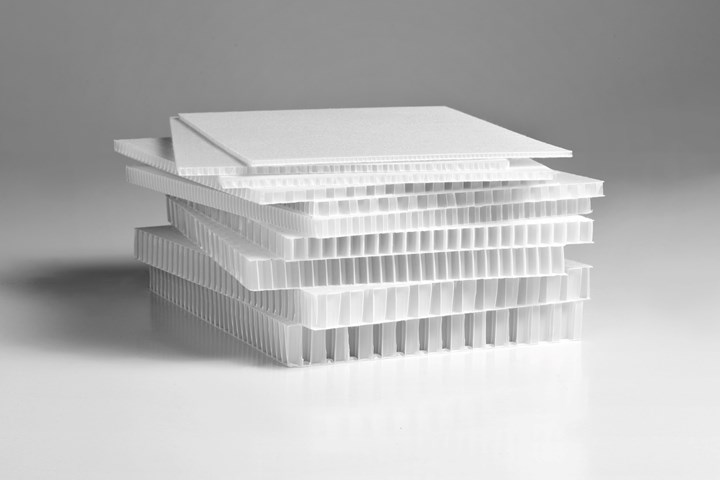

EconCore (Leuven, Belgium) and ThermHex (Halle, Germany) are providing U.S. industry professionals a first look at new product variations made in Germany. These demonstrations include honeycomb cores in a range of chemistries, such as polypropylene (PP) cores and high-performance thermoplastics for aerospace applications, as well as in panels for lightweight solar modules.

ThermHex’s production process is based on EconCore’s patented production technology, which enables the company to continuously produce honeycomb cores that combine both the mechanical properties and the minimal weight of honeycomb with automated and low-cost production, with a thickness range of 3 to 30 mm. Besides weight savings and cost reduction, they also offer improved surface quality over competing materials.

Sandwich panels with glass fiber-reinforced PP unidirectional (UD) tape skins and a ThermHex PP honeycomb core will be highlighted at CAMX. These panels are said to offer high rigidity at minimum weight, and are versatile for a range of applications. The use of thermoplastics not only enables the forming of complex, functionalized components, but also has a more resource-efficient and less expensive production process than conventionally produced sandwich components.

A large-sized solar panel module will also be on display. ThermHex and Solarge have intensively collaborated to reduce panel weight by replacing heavy glass with a composite honeycomb structure and polymer frontside. The result is a fully recyclable alternative to more traditional non-sustainable materials. A panel measuring a little more than 2.66 m2 is said to weigh 14.5 kg, compared to more than 28 kg with the old glass-type model.

EconCore’s high-performance thermoplastic cores are based on polyphenylene sulfide (PPS) and polyetherimide (PEI) polymers. PPS and PEI honeycomb cores offer high levels of strength and stiffness in compression and shear, high-temperature stability and optimized weight-to-cost ratios. HPT honeycombs build on the pre-existing intrinsic benefits of lightweight honeycomb structures by increasing heat stability and fire resistance, making them a suitable choice for applications in railway and aircraft interiors. Together with Airbus, the Technical University of Denmark (DTU) and Fraunhofer, EconCore is currently working on a new technology for a more sustainable type of rudder for a short- and medium-range aircraft based on thermoplastic honeycomb sandwich composites.

Related Content

-

CAMX 2022 exhibit preview: Scott Bader

Scott Bader North America showcases its Crestabond and Crestomer structural adhesives, Crestafix bonding pastes, Crestapol urethane acrylate resins and Crestamould tooling systems.

-

Reusable vacuum bagging solutions for composite applications

CAMX 2023: Smartech underscores its industrial reusable vacuum bagging products for reduced waste, easy debulking and the capability to be used for complex projects.

-

CAMX 2023 exhibit preview compilation, Part 2

Part 2 continues to showcase the materials, services, machinery, live demonstrations and other innovations presented by CAMX 2023 exhibitors.