CAMX 2014 exhibit previews, part 2

With CAMX 2014 less than a week away (Oct. 13-16, Orlando, Fla.), CompositesWorld offers a final glimpse of some of the products, technologies and services that you will find in booths in the Exhibit Hall. During the show, we'll keep you informed and up-to-date with the CAMX Show Daily, which will be distributed Tuesday, Wednesday and Thursday at the show. Safe travels to Orlando and we look forward to seeing you at the conference and trade show.

With CAMX 2014 less than a week away (Oct. 13-16, Orlando, Fla.), CompositesWorld offers a final glimpse of some of the products, technologies and services that you will find in booths in the Exhibit Hall. During the show, we'll keep you informed and up-to-date with the CAMX Show Daily, which will be distributed Tuesday, Wednesday and Thursday at the show. Safe travels to Orlando and we look forward to seeing you at the conference and trade show.

- Aeron Composites: Glass, carbon fiber products for corosion applications

- Aramicore Compsite: Aramid paper honeycomb

- Assembly Guidance Systems: Laser monitoring and control systems

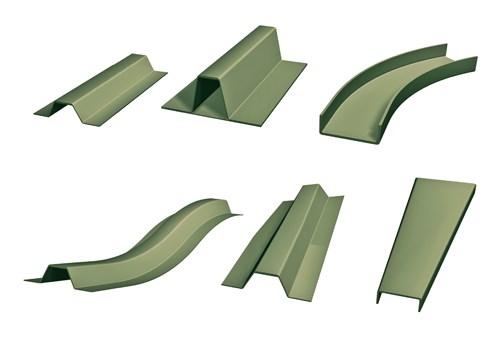

- ATK Aerospace Structures: Automated stiffener forming technology

- Austrian Advanced Lightweight Technology: R&D consortium services

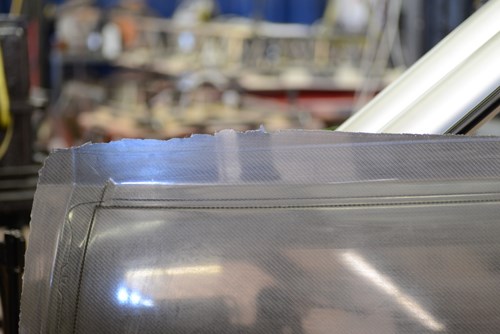

- Automated Dynamics: Thermoplastic composite aerostructures

- Benecor: Metallic honeycomb core structures

- Chomarat: Thin-ply fiber reinforcements

- Componeering: Composites design and analysis

- Conductive Composites: Conductive composite structures and technologies

- CoreLite: Balsa wood and PVC foam core solutions

- Cornerstone Research Group: No-oven, no-autoclave composites

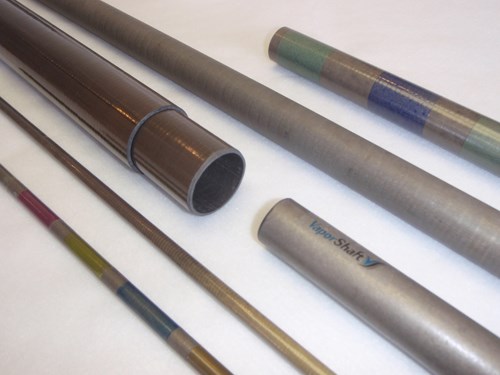

- Current: Laminated sheet, rods, tubing

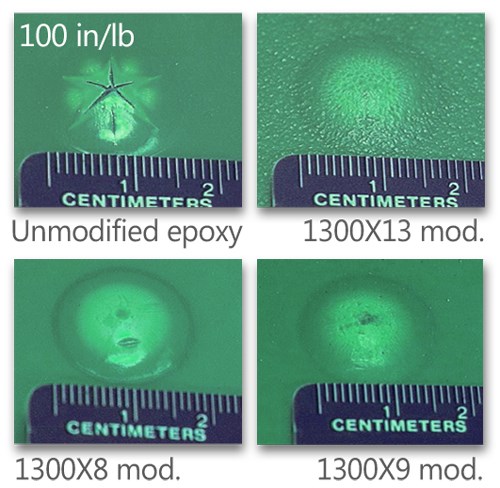

- CVC Thermoset Specialties: Resins, curatives, modifiers, toughening agents

- DeltaTrak: Cold chain material management solutions

- Electron Heat: Radio-frequency radiation curing systems

- Entec Composite Machines: High-speed filament winding machines

- E.V. Roberts: Composite material distribution services

- Fibrtec: Thermoplastic composite resin systems

- Genesis Systems: Non-destructive evaluation solutions

- Graco: Resin handling for prepreg manufacturing

- Highland Composites: Composites fabrication services

- Imetrum: Noncontact video system

- Innegra Technologies: Olefin-based fiber reinforcement products

- Janicki Industries: Design, tooling, prototyping and manufacturing services

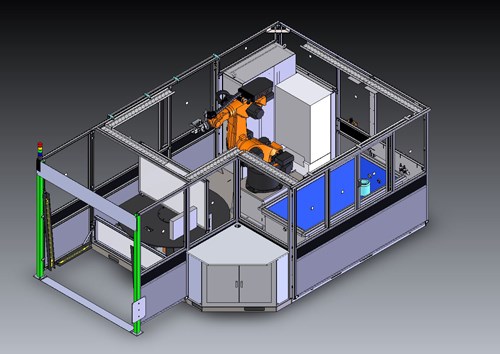

- JHM Technologies: High-pressure RTM technologies

- Laser Projection Technologies/Delta Sigma: 3-D optical projecters

- Laser Technology: Non-destructive testing systems

- LEWCO: Batch ovens, conveyor ovens

- Lingrove: Bio-based prepregs and fiber reinforcements

- Luna: Embedded optical fiber systems

- MCC Equipment & Service Center: Sprayup systems distribution services

- Nederman: Dust containment and capture systems

- Norton Saint-Gobain: Abrasives and refinishing systems

- Northern Composites: Composite materials distribution services

- Pacific Coast Composites: Composites distribution services

- PlastiComp: Long fiber thermoplastic materials and technologies

- Polystrand: Thermoplastic composite materials and manufacturing

- RAMPF: Modeling and moldmaking materials

- Regloplas: Pressurized water mold temperature controllers

- RST-5 USA: Green solvent cleaning solutions

- SAERTEX USA: Multiaxial and 3-D non-crimp fabrics

- Solid Concepts: 3-D printing technologies

- Sunstrand: Natural fiber reinforcement products

- Tecnatom: Non-destructive testing solutions

- Technical Fibre Products: Carbon fiber and thermoplastic nonwovens and veils

- Trillion Quality Systems: 3-D optical measurement devices

- TSE Industries: Bio-based sprayup resin systems

- Volume Graphics: Non-destructive analysis systems

- Aligned Vision

Related Content

-

Innovation in ultrasonic inspection and nondestructive testing

With increasingly complex structural components working their way into aerospace programs, the need for versatility in inspection and testing capabilities is growing.

-

MoviTHERM opens in-house NDT lab

New inspection techniques, excitation sources and infrared cameras enhance feasibility study capabilities for customers in the composites industry.

-

UTComp authors bulletin on fitness-for-service assessment of FRP

Welding Research Council (WRC) Bulletin 601 provides technical background and validation for quantitative nondestructive testing methodology for FRP composite equipment.