Australian research group launches carbon fiber manufacturing

CSIRO has begun manufacture of Australia’s first carbon fiber sourced entirely from materials produced in the country. Fiber quality is automotive grade, but the organization has its sights set on aerospace grade material.

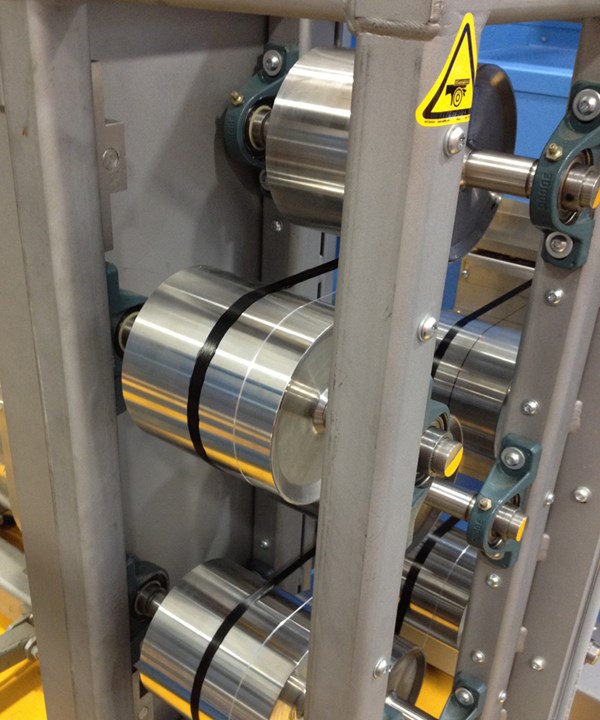

CSIRO carbon fiber manufacturing line

CSIRO carbon fiber manufacturing lineThe Commonwealth Scientific and Industrial Research Organisation (CSIRO, Canberra, Australia) says its scientists have produced Australia’s first entirely homegrown carbon fiber, paving the way for Australian industry to mass-produce the material.

Australia’s first carbon fiber was produced using polyacrylonitrile fiber, spun on the joint CSIRO/Deakin University wet spinning line, then carbonized at Deakin’s Carbon Nexus facility.

“From wind turbines to aerospace, even the latest Mustang wheels, a carbon fiber industry signals the kind of reinvention needed across Australian industry, shifting our focus from raw exports to high-value products to retain our global competitive advantage,” says Dr. Larry Marshall, chief executive of CSIRO. “This is another chapter in the innovation history of Geelong, where Australia’s first carbon fiber was created from scratch using CSIRO-produced white fiber. It’s a major leap forward in turning the region into an international carbon fiber hub.”

“We want to unlock carbon fiber’s full potential. On our first attempt, we created car-quality carbon fiber – we now expect to improve on that result and produce aerospace-standard carbon fiber,” says CSIRO research director Dr. John Tsanaktsidis.

“CSIRO’s Advanced Manufacturing Roadmap, released in November 2016, called on Australian industry to play to its strengths by focusing on high-value advanced manufacturing. Creating a future industry based on carbon fiber is an excellent example of bringing that to life.”

Related Content

-

Materials & Processes: Composites fibers and resins

Compared to legacy materials like steel, aluminum, iron and titanium, composites are still coming of age, and only just now are being better understood by design and manufacturing engineers. However, composites’ physical properties — combined with unbeatable light weight — make them undeniably attractive.

-

Plant tour: Joby Aviation, Marina, Calif., U.S.

As the advanced air mobility market begins to take shape, market leader Joby Aviation works to industrialize composites manufacturing for its first-generation, composites-intensive, all-electric air taxi.

-

Materials & Processes: Resin matrices for composites

The matrix binds the fiber reinforcement, gives the composite component its shape and determines its surface quality. A composite matrix may be a polymer, ceramic, metal or carbon. Here’s a guide to selection.