Additive Manufacturing/ 3D Printing Using Composites

Additive manufacturing, commonly known as 3D printing, has revolutionized composite production by enabling the layer-by-layer construction of intricate composite structures. In the realm of composites, additive manufacturing techniques allow for the creation of complex geometries with precise fiber orientations and resin distribution, optimizing material performance. This technology offers the flexibility to customize parts, reduce waste, and experiment with novel composite combinations. By depositing materials layer upon layer, additive manufacturing facilitates the production of lightweight, high-strength components tailored for specific applications in industries such as aerospace, automotive, and healthcare, pushing the boundaries of what's achievable in composite design and fabrication.

ESSENTIAL READING

VIEW ALLMaterials & Processes: Fabrication methods

There are numerous methods for fabricating composite components. Selection of a method for a particular part, therefore, will depend on the materials, the part design and end-use or application. Here's a guide to selection.

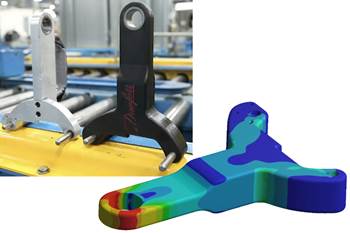

Read MoreHow to validate 3D-printed composite part performance

Integrated Computational Materials Engineering (ICME) workflow simulates composite material performance to speed development, optimize performance and reduce costs for a redesigned 3D-printed CFRP bracket.

Read MoreContactless measurement of temperature, pressure in composites

Magnetic microwires enable contactless measurement of temperature and pressure during cure and in service.

WatchKnowledge Centers

In the Automated Composites knowledge center, CGTech brings you vital information about all things automated composites, from the manufacturing processes to the vendors and necessary tools.

LEARN MORELatest Additive Manufacturing News And Updates

Siddus Space launches composites-intensive LizzieSat satellite

LizzieSat offers space-based data collection and analysis for SpaceX’s Transporter-10 Rideshare mission.

Read MoreSwinburne-CSIRO Testlab grows composites competency via industrial-scale 3D printing

Industry 4.0 facility is integrating an additive manufacturing approach to its holistic processes to optimize composite component production rates, quality and cost.

Read MoreMARS Center grows LFAM capabilities with JuggerBot 3D Tradesman Series

P3-44 pellet-fed 3D printer is capable of leveraging a range of fiber-reinforced composite materials, to be used for the production of high-fidelity components in aerospace and defense.

Read MoreCEAD, Adaxis launch “AdaOne for Flexbot” software integration

Collaborative effort results in a software experience that seamlessly integrates with CEAD’s Flexbot systems, aiming to elevate the efficiency in robotic large-format 3D printing with composites.

Read MoreCarbon Conversions offers 3D printing filament reinforced with rCF

Development of re-Evo TDR products that work on a majority of 3D printers is now an available option for companies sending in their carbon fiber waste.

Read MoreAirtech, Caracol grow LFAM with Dalhtram resins, Heron AM pairing

New partnership will see Dahltram resins qualified for integration with Caracol’s Heron AM platform.

Read MoreFeatured Posts

Industrializing additive manufacturing in the defense/aerospace sector

GA-ASI demonstrates a path forward for the use of additive technologies for composite tooling, flight-qualified parts.

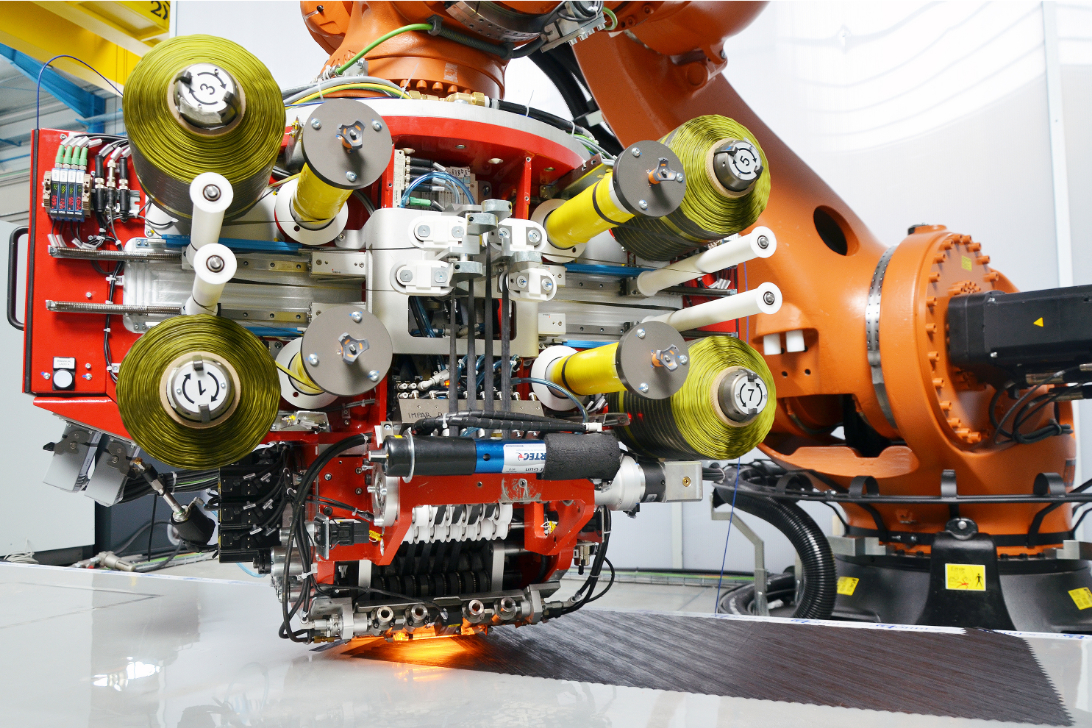

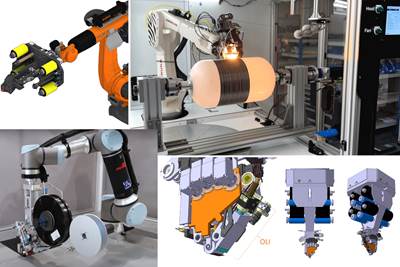

Read MoreThe next evolution in AFP

Automated fiber placement develops into more compact, flexible, modular and digitized systems with multi-material and process capabilities.

Read MoreMulti-material, self-sensing, 3D-printed scoliosis braces

Startup Fited and Brightlands Materials Center have developed a lighter weight, thinner CFRP corrective brace, including pressure sensors made from continuous carbon fibers.

WatchIncreased molding productivity via additive manufacturing

Companies in multiple segments turn to 3D printing for end-of-arm tools, fixtures for increased safety and functionality, lower cost and faster turnaround times.

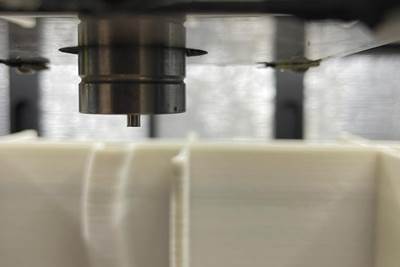

Read MoreMold 3D printing helps automate composite bathtub, shower production

As part of its efforts to automate as much of its production process as it can, Lyons Industries acquired a Massivit 10000 additive manufacturing system to quickly produce high-performance molds and support fixtures.

WatchA new era for ceramic matrix composites

CMC is expanding, with new fiber production in Europe, faster processes and higher temperature materials enabling applications for industry, hypersonics and New Space.

Read MoreFAQ: Additive Manufacturing

What is additive manufacturing in composites?

Additive manufacturing, also known as 3D printing, in composites involves the layer-by-layer deposition of composite materials, such as continuous fibers or chopped fibers within a matrix, to create complex parts or structures.

What types of additive manufacturing methods are used for composites?

Various methods are employed, including Fused Filament Fabrication (FFF), Continuous Fiber 3D Printing (CFF), Binder Jetting, Directed Energy Deposition (DED), and others that selectively deposit materials to build composite parts.

What composite materials can be used in additive manufacturing?

Additive manufacturing processes can work with a range of composite materials, such as carbon fiber-reinforced polymers (CFRPs), glass fiber composites, and even advanced materials like nanocomposites or hybrid composites.

What is Formnext Chicago?

Formnext Chicago is an industrial additive manufacturing expo taking place April 8-10, 2025 at McCormick Place in Chicago, Illinois.

Formnext Chicago is part of a series of Formnext events in the U.S. being produced by Mesago Messe Frankfurt, AMT – The Association For Manufacturing Technology, and Gardner Business Media (our publisher).

Here is the full lineup of Formnext events in North America:

- Formnext Forum Austin took place in August 2023 and will return to Texas in 2026.

- Additive Manufacturing Sector Powered by Formnext at IMTS in 2024

- Formnext Chicago in 2025

What are the advantages of additive manufacturing in composites?

Benefits include the ability to create complex geometries, lightweight structures, reduced material waste, customization, rapid prototyping, and the integration of functional features within parts.

Are there limitations to additive manufacturing in composites?

Challenges include limitations in scaling for large-scale production, post-processing requirements, ensuring consistent mechanical properties, and the need for advancements in material options.

.jpg;maxWidth=300;quality=90)