Janicki Industries

719 Metcalf Street

Sedro-Woolley, WA 98284 US

888-856-5143 | 360-856-5143

janicki.com

About Janicki Industries

IS THIS YOUR COMPANY?

As Seen On CompositesWorld

Janicki Industries Supplies the Following Products

- Aerospace, flight control surfaces

- Aerospace, fuselage/wing

- Automotive, body panels & substructures

- Carbon fiber composite

- Carbon/carbon composites

- Composite, other

- Cutting, finishing, and machining

- Fiberglass composite

- Hand layup

- Mandrels, other

- Marine, boat (hulls, decks, bulkheads, etc.)

- Metal, aluminum

- Metal, steel

- Moldmaking and patternmaking

- Other composite structures

- Prototyping

- Vacuum-assisted resin transfer molding (VARTM)

Editorial, News, and Products

-

Janicki receives Northrop Grumman Supplier Excellence Award

Designer and builder of tools, parts, prototypes and assemblies earns recognition for supporting defense manufacturing and distribution goals.

-

Janicki receives Boeing 2023 Supplier of the Year Award

Composite and metallic tooling, equipment and parts supplier has been recognized for its collaboration, commitment and overall support of various Boeing programs.

-

Janicki supports Saildrone Voyager program

Engineer and manufacture of technologically challenging composite components for the 33-foot uncrewed surface vehicle will scale up Saildrone fleet capability, meet the demanding challenges of ocean mapping.

-

Natilus partners with Janicki for blended wing autonomous aircraft

The Tier 1 supplier will design, fabricate and provide quality assurance of primary composite structures for the Natilus N3.8T prototype, to be used for air freight transport.

-

Materials & Processes: Tooling for composites

Composite parts are formed in molds, also known as tools. Tools can be made from virtually any material. The material type, shape and complexity depend upon the part and length of production run. Here's a short summary of the issues involved in electing and making tools.

-

SAMPE North America to host Materials Innovation & Advanced Technology Leadership Forum

The Jan. 26-27, 2022, conference held in Huntington Beach, Calif., convenes composites stakeholders from a variety of end markets to address the industrialization of composites manufacturing.

-

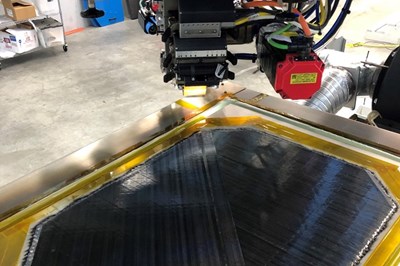

Electroimpact, Toray, Janicki advance technologies for rapid, large-scale thermoplastic parts manufacture

Project combines Electroimpact high-speed AFP equipment, Janicki’s OOA heated layup tooling system and Toray Cetex TC1225 low melt PAEK UD tape for deposition rates of up to 4,000 inches/minute.

-

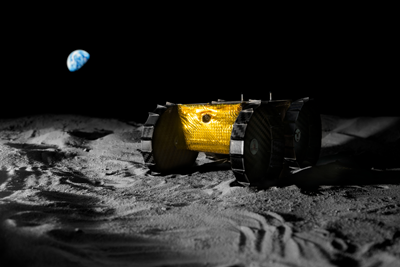

Composites design helps nano-sized lunar rover hit big milestones

Developed by Carnegie Mellon University, the ultralight, composites-intensive Iris nano-rover will make its lunar debut later this year.

-

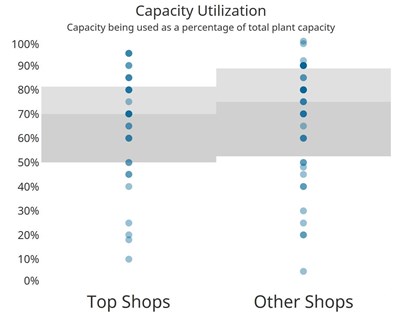

2020 CW Top Shops recognizes top-performing facilities

CW's second annual Top Shops benchmarking survey helps composites fabricators put their operations into perspective and illuminates top-ranking facilities.

-

CAMX 2020 exhibit preview: Janicki Industries

Janicki Industries is featuring its fast prototyping process for flyaway parts and tooling for urban air mobility (UAM) vehicle manufacturers.

-

Composites suppliers, fabricators respond to coronavirus

Companies across the composites industry supply chain share how the COVID-19 pandemic is affecting their businesses, and how they are available to help.

-

Top composites news stories of 2019

The top 10 most viewed composites news stories of 2019.

-

Urban air mobility: The action heats up

Columnist Dale Brosius reflects on the current state of the under-development urban air mobility (UAM) market, where it’s headed, and what it all means for the composites industry.

-

Janicki Industries opens aerospace composite manufacturing plant

The 90,000-square-foot facility in Hamilton, Wash., U.S., will produce carbon fiber composite aerospace parts.

-

Third Wave Systems models 5-axis machined composite components

Developed under a RIF with the USAF, engineers demonstrated improved production processes for several current warfighter composite components.

-

Janicki Industries approved for Nadcap accreditation

US-based composites tooling and manufacturing specialist Janicki Industries has been granted Nadcap approval through 2020.

-

Vartega shows positive results of recycled carbon fiber testing

US-based Vartega Carbon Fiber Recycling has begun characterization of its material, and has received a letter of support from Janicki Industries, which will start to assess the fiber as well.

-

CW Ideas in Action

Ideas are just ideas until someone does the hard work of putting them into action and seeing results. CW's editors, therefore, inaugurate an annual review of Ideas in Action, celebrating a handful of hot concepts that could make those who conceived them "household names."

-

Tooling (2015)

Composite parts are formed in molds, also known as tools. Tools can be made from virtually any material. The material type, shape and complexity depend upon the part and length of production run. Here's a short summary of the issues involved in electing and making tools.

-

IBEX 2014 report

A new home port in Florida and fair economic winds propel this boatbuilders’ convention to its best exhibitor/attendee turnout in years.

-

CAMX 2014 exhibit previews, part 2

With CAMX 2014 less than a week away (Oct. 13-16, Orlando, Fla.), CompositesWorld offers a final glimpse of some of the products, technologies and services that you will find in booths in the Exhibit Hall. During the show, we'll keep you informed and up-to-date with the CAMX Show Daily, which will be distributed Tuesday, Wednesday and Thursday at the show. Safe travels to Orlando and we look forward to seeing you at the conference and trade show.

-

Composites steady radio telescope reflector

Precise carbon fiber-reinforced dish prototype could be the model for as many as 2,500 telescopes in the Square Kilometre Array.

-

Janicki Industries: Breaking the mold

Once known only as a toolmaker, Janicki offers unique precision, production capability and problem solving as it pioneers leading-edge composites technology.

-

The pleasures of plant tours

HPC editor-in-chief Jeff Sloan comments on how infrequently he is invited to tour the plant of a composites manufacturer yet how valuable it is, when he does, to get a glimpse of the culture and personality within those walls.

-

Tooling for composites: Evolutionary trajectory

New technologies and improved methods keep up as tools get bigger and more complex and toolmaking gets ever more challenging.

-

Advanced Composite Cargo Aircraft proves large structure practicality

Dr. John Russell reports that the successful completion of a flying aircraft in the the Advanced Composite Cargo Aircraft program has demonstrated the holistic impact that composites technology can have on future aircraft development.

-

Skinning the F-35 fighter

Fastening the all-composites skin on the Lightning II requires machining and drilling technology that is optimized for cost-efficiency.

-

Never Never Land

Once upon a time there were two buyers and two tooling suppliers . The first buyer needed some tools for a well-funded project.

-

RETOOLING THEORY AND PRACTICE

To meet the critical need for knowledgeable composites engineers and technicians, public/private partnerships are molding new applications-driven and transportable educational models.

-

Tooling And Toolmaking Innovations Continue

New products and practices advance the efficiency and economy of advanced composite part production.

-

Composites combat ready in UCAVs

As unmanned aircraft are designed from inception for combat duty, composites will carry the payloads in structural components.

-

New Approaches To Cost-effective Tooling

New methods, materials and philosophies add up to tooling innovations.