Molded Fiber Glass Companies

2925 MFG Pl.

PO Box 675

Ashtabula, OH 44005 US

800-860-0196 | 440-997-5851

moldedfiberglass.com

About Molded Fiber Glass Companies

IS THIS YOUR COMPANY?

As Seen On CompositesWorld

Molded Fiber Glass Companies Supplies the Following Products

- Adhesive bonding

- Aerospace, radomes

- Armor, composite

- Automated fiber placement

- Automated fiber placement

- Automotive, body panels & substructures

- CAD/CAM/CAE design

- Civil engineering

- Coating and painting

- Coating and painting

- Compression molding

- Compression molding

- Consulting, materials

- Consulting, process development

- Consulting, procurement/purchasing/specification

- Custom compounding and blending

- Custom compounding and blending

- Cutting, finishing, and machining

- Cutting, finishing, and machining

- Fiberglass composite

- Hand layup

- Honeycomb structures

- Infrastructure, composite

- Inspection services

- Integrally heated

- Laminate panels, with core

- Laminate sheets, solid

- Materials analysis

- Metal bonding

- Metal bonding

- Metal, aluminum

- Metal, nickel shell

- Metal, steel

- Moldmaking and patternmaking

- Other composite structures

- Other fabricating services

- Other thermoset fabricating services

- Preform screens

- Product design

- Prototype

- Prototyping

- Prototyping

- Repair services, composites

- Sprayup

- Testing, materials

- Testing, product

- Testing, structural

- Vacuum-assisted resin transfer molding (VARTM)

Editorial, News, and Products

-

Ashland Global Holdings awarded 2020 Supplier of the Year

The company’s performance adhesives team was awarded by Molded Fiber Glass Co. for exceeding performance expectations and consistent customer support.

-

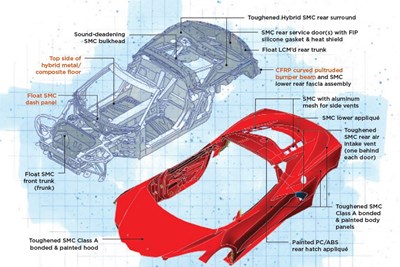

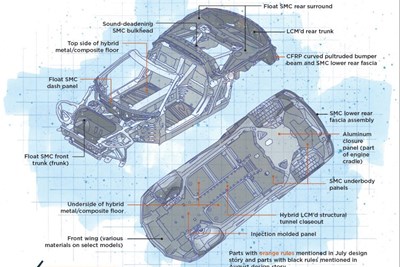

Composites-intensive masterwork: 2020 Corvette, Part 2

Innovative composite materials trim mass, costs and noise on the high-volume mid-engine sports car.

-

Composites-intensive masterwork: 2020 Corvette, Part 1

Eighth-generation vehicle sports more composites, and features parts produced using unique materials and processes.

-

Corvette: A multi-material success history

At the launch of the 2020 C8, Columnist Dale Brosius reflects on the iterations of multi-material innovation in the manufacture of Corvettes over its history.

-

2019 SPE Automotive Innovation Awards winners announced

Among the winners and finalists, a wide range of technologies demonstrate composites’ benefits for ground transportation.

-

The long view for composites in long-haul trucks

Composite components on heavy trucks and trailers continue to grow, both in volume and in kind, but they won’t be carrying structural loads until the mid-2020s.

-

SMC: Old dog, more tricks

In the sheet molding compound renaissance, the advent of new resins and compounds are broadening the definition and application of this versatile family of composites.

-

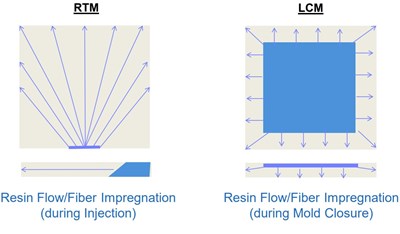

Wet compression molding

Automated process cuts cycle time and cost for CFRP parts with potential for 65% fiber volume via Dynamic Fluid Compression Molding variant.

-

CAMX 2014 show report

Bigger, better and more inclusive than any previous U.S. composites trade event, the inaugural show turns North American eyes forward to the future.

-

Wind blades: Progress and challenges

Despite double-digit wind energy industry growth, turbine blade manufacturers and materials suppliers acknowledge a pressing need to reduce costs and innovate.

-

Training surge: Too little, too late?

Hands-on programs are aimed at younger students by educators hoping to prevent shortages of composites technicians and engineers.

-

Blade repair: Closing the maintenance gap

Citing difficult work conditions, lack of OEM guidance and underdeveloped inspection technologies, those who service wind turbine blades seek remedial solutions.

-

The state of education in the composites trade, part II

Andre Cocquyt (GRPguru.comm, Brunswick, Maine) continues his call for a unified national composites education standard, and suggests a practical way forward toward that goal.

-

Composites 2010 Product Showcase

The ACMA’s Las Vegas exhibition reflected an industry in recovery.

-

Wind turbine blades: Big and getting bigger

Two decades of technical and market development has made this once marginal application a global giant and one of the world’s largest markets for composites.

-

NAIA Show Highlights

The 2007 Detroit Auto Show emphasizes “green” themes and high performance.

-

Corvette converts floor panels, wheelhousings from glass to chopped carbon

Since 1953, General Motor's Chevrolet Corvette has been a trendsetter in glass-reinforced automotive composites and has served as the test bed for many GM innovations.

-

Passenger Safety: Flame, Smoke and Toxicity Control

Tried, true -- and some new -- FST-resistant products for manufacturers of composites in rail- and road-based people movers.

-

2005 NAIA Show highlights

Detroit Auto Show emphasizes powerful and eco-friendly vehicles.