Managing the composite material supply chain: The Demand Aggregation Imperative

Guest columnist Trevor Stansbury, founder and president of Supply Dynamics (Cincinnati, Ohio), emphasizes the Demand Aggregation Imperative.

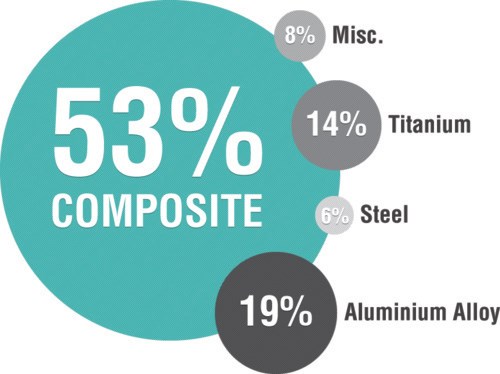

The widespread adoption of composite materials is fueling an increase in world demand that is expected to double by 2015. The automotive, marine and energy sectors will account for a large percentage of the projected increase. The balance is expected to be driven by demand for lighter, more efficient next-generation aircraft, including The Boeing Co.’s (Chicago Ill.) 787 Dreamliner and the Airbus (Toulouse, France) A350 XWB, with airframes of 50 percent or more carbon fiber composite, by weight.

This rapid growth is leading OEMs to reevaluate existing supply chain strategies and operating models. Take, for example, the composite supply-related delays that postponed initial deliveries of Airbus’ A380 and Boeing’s 787. The disclosure of these delays caused severe financial consequences on Wall Street, underscoring the importance of understanding the material inputs, the need for multi-tier transparency, and closer collaboration with sub-tier suppliers.

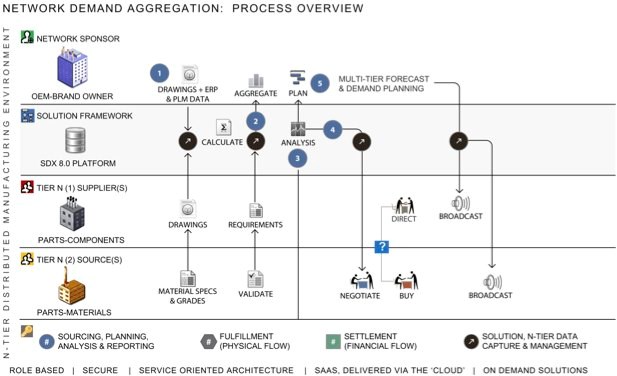

In response, a number of leading OEMs have committed to proactively orchestrating critical parts of the extended value chain on behalf of their supply networks. Many have already taken an important first step by implementing Material Demand Aggregation strategies that provide valuable intelligence and offer advanced analytics about their collective production spend for various commodities — that is, the total amount spent for metals, plastics, electronics and fastening systems. It stands to reason that aggregating demand for composite materials is a logical fit with this strategy.

The reality is that companies compete and are valued, in part, on the basis of their supply network’s performance. In other words, companies no longer compete against companies; supply chains compete against supply chains. Our perspective is that aggregating network spend is a critical business imperative and a competitive differentiator.

Today, most OEMs are organized around product design and final assembly. Having transformed themselves from vertically integrated to virtually integrated enterprises, they now depend heavily on globally distributed networks of contract manufacturers for the majority of their components and assemblies. In many cases, they have delegated complete responsibility to their part suppliers for the source selection and purchase of material inputs. Consequently, numerous commodity strategies and sourcing activities co-exist that are neither shared nor coordinated across operational business units or with contract manufacturers within a given supply chain. It would not be uncommon to discover an OEM competing with its own sub-tier supplier in the same market, to secure the same material or production capacity. Further complicating matters, most OEMs’ forecasting and planning processes while sophisticated, are linear, extending only to the purchased part level. As a result, sub-tier suppliers are forced to interpret and act against a cascading demand signal they receive. This inevitably drives reactive behavior — the OEM is perpetually firefighting costly supply-related issues after they have caused delays and cost overruns.

Companies that recognize the power and value of understanding part-material flows have made significant strides toward managing supply risk and realizing sustainable cost savings, ranging from 8 to 15 percent of their costs of goods sold. This is achieved through improved forecasting and planning efficiencies that drive out excess inventories throughout the extended value chain. The strategy’s cornerstone is a systematic approach to the assembly of aggregate — that is, sum-total — views of production materials. The scope covers network material spend, irrespective of whether production materials are purchased directly for internal consumption or purchased and consumed by contract manufacturers.

It is important to note that the value drivers and sourcing strategies associated with Demand Aggregation Programs frequently differ, based on market conditions, the targeted commodity groups and other factors. For example, when it comes to the aggregation of metals, standardization by form, grade, size and specification is often a natural next step after an OEM has realized the benefits of leveraging its scale to improve pricing.

Such strategies similarly apply to composite raw materials inputs. The aggregation and standardization of resin formula components and fiber forms, grades and sizes, and other items are ideal candidates. The ability to translate composites demand into elemental constituents also can support financial risk management strategies by enabling OEMs, mills and composite materials or part manufacturers or distributors to hedge price volatility. Where there is competition to secure limited production capacities (e.g., carbon fiber), an understanding of aggregate spend will enable the OEM to make volume commitments to ensure supply continuity. Materials used in high volumes (e.g., fasteners) can be leveraged for improved commercial pricing or to simply guarantee that a $12 bolt never holds up the shipment of a $200,000 assembly. It all begins with reconnecting raw materials to components, assemblies, capacities, processes and finished goods.

Of the risk factors in the composites supply market, the following three alone justify aggregation:

- Competition for limited capacities (e.g., the increase of automotive applications vs. aerospace demand)

- The security and continuity of carbon fiber production and supply.

- The comparatively short shelf life and related planning issues of epoxy resins and prepreg materials.

We expect that companies will continue to adopt strategies, such as Material Demand Aggregation, to create competitive advantages in forecasting, procurement and standardization of composite materials. We predict that sustainable cost reductions of 8 to 15 percent, already achieved for other production materials, can be realized for composites. Forecasting and managing the more efficient allocation of costly (and often perishable) composite materials across the extended supply chain is a winning strategy — one worth pursuing.

Related Content

Thermoplastic composites welding advances for more sustainable airframes

Multiple demonstrators help various welding technologies approach TRL 6 in the quest for lighter weight, lower cost.

Read MoreCryo-compressed hydrogen, the best solution for storage and refueling stations?

Cryomotive’s CRYOGAS solution claims the highest storage density, lowest refueling cost and widest operating range without H2 losses while using one-fifth the carbon fiber required in compressed gas tanks.

Read MorePlant tour: Joby Aviation, Marina, Calif., U.S.

As the advanced air mobility market begins to take shape, market leader Joby Aviation works to industrialize composites manufacturing for its first-generation, composites-intensive, all-electric air taxi.

Read MorePlant tour: Spirit AeroSystems, Belfast, Northern Ireland, U.K.

Purpose-built facility employs resin transfer infusion (RTI) and assembly technology to manufacture today’s composite A220 wings, and prepares for future new programs and production ramp-ups.

Read MoreRead Next

CW’s 2024 Top Shops survey offers new approach to benchmarking

Respondents that complete the survey by April 30, 2024, have the chance to be recognized as an honoree.

Read MoreComposites end markets: Energy (2024)

Composites are used widely in oil/gas, wind and other renewable energy applications. Despite market challenges, growth potential and innovation for composites continue.

Read MoreFrom the CW Archives: The tale of the thermoplastic cryotank

In 2006, guest columnist Bob Hartunian related the story of his efforts two decades prior, while at McDonnell Douglas, to develop a thermoplastic composite crytank for hydrogen storage. He learned a lot of lessons.

Read More