Multimaterialism is back in the Audi A8

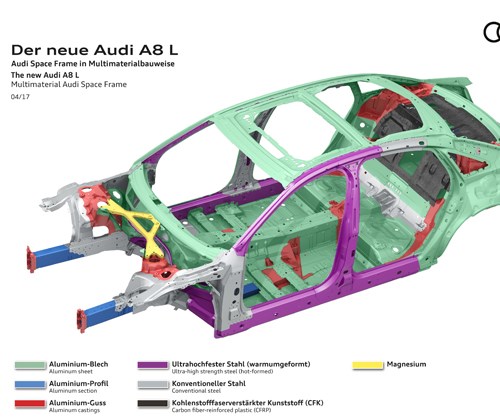

Audi shares details about the use of carbon fiber composites, steel, aluminum and magnesium in the Audi Space Frame (ASF) for the next-generation A8.

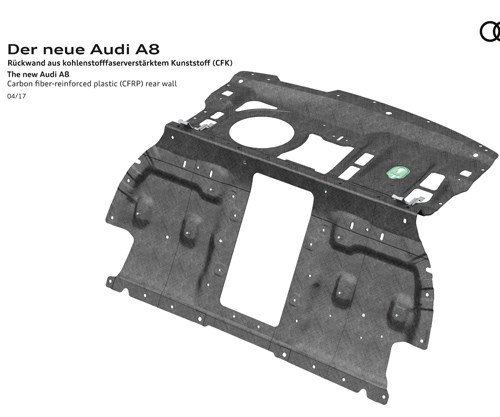

The Audi Space Frame (ASF) for the Audi A8 features a carbon fiber composite wall separating the passenger compartment from the rear trunk space.

German automaker Audi has become the latest automotive OEM to get into the multimaterial business, reporting extensively on the use of carbon fiber, steel, magnesium and aluminum in the next-generation Audi A8. The multimaterial ethos is expressed most clearly in the Audi Space Frame (ASF, pictured above).

In terms of its overall dimensions, an ultra-high-strength, torsionally rigid rear panel made of CFRP is the largest component in the occupant cell of the new Audi A8, and Audi says it contributes 33% to the torsional rigidity of the total vehicle. To optimally absorb longitudinal and transverse loads as well as shearing force, the part uses six to 19 layers of carbon fiber tapes 50 mm/2.0 inches wide. Audi says it made the part using an automated, direct dry fiber placement process specially developed for this purpose. After the dry fiber is placed, the entire stack is preformed and then molded via high-pressure resin transfer molding (HP-RTM). Carbon fibers were supplied by Zoltek (St. Louis, MO, US).

CFRP rear wall for the Audi A8.

A combination of hot-formed steel components make up the occupant cell, which comprises the lower section of the front bulkhead, the side sills, the B-pillars and the front section of the roof line. Some of these sheet metal blanks are produced in varying thicknesses using tailoring technologies – meaning they are customized – and others also undergo partial heat treatment. That reduces weight and increases the strength, especially in areas of the vehicle that are particularly critical for safety.

Aluminum components make up 58% of the new Audi A8 body, the largest share in the mix of materials. Cast nodes, extruded profiles and sheets are the elements characteristic of the ASF design. And here too the competition of materials has been driving progress. New heat-treated, ultrahigh-strength cast alloys attain a tensile strength of more than 230 MPa. The corresponding yield strength in the tensile test is more than 180 MPa, and for the profile alloys it is 320 MPa – values that Audi says are significantly higher than seen previously.

Rounding out the mix of materials is the magnesium strut brace. A comparison with the predecessor model shows that it provides 28% weight savings. Aluminum bolts secure the connection to the strut tower domes, making them a guarantor of the body’s high torsional rigidity. In the event of a frontal collision, the forces generated are distributed to three impact buffers in the front end.

Related Content

-

From the CW Archives: Airbus A400M cargo door

The inaugural CW From the Archives revisits Sara Black’s 2007 story on out-of-autoclave infusion used to fabricate the massive composite upper cargo door for the Airbus A400M military airlifter.

-

The state of recycled carbon fiber

As the need for carbon fiber rises, can recycling fill the gap?

-

Composite resins price change report

CW’s running summary of resin price change announcements from major material suppliers that serve the composites manufacturing industry.