Concrete composite that heals itself

The concept of self-healing materials isn’t new, however, there’s been a renewed interest in the technology due to the maintenance needs of deteriorating infrastructures.

Mustafa Sahmaran, professor at Gazi University, tests the performance of healed ECC specimen under mechanical loading. Image courtesy of the American Concrete Institute.

It’s no secret the human body can do some amazing things. If you cut your hand, it will heal automatically. Right after you fall and skin your knees, your body is already working to repair the wound. Our bodies are designed to heal from small wounds on its own. And it turns out, we share that characteristic with concrete. The world’s most popular building material can self-heal its own small wounds (aka cracks) as an intrinsic characteristic.

However, unlike the human body, cracks do not heal easily in conventional concrete due to its brittle nature. And this is where Engineered Cementitious Composites (ECC) look to come in. ECCs are based on an advanced material technology first proposed by Victor C. Li from University of Michigan in Ann Arbor.

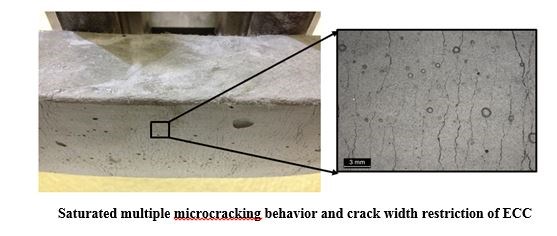

Unlike the conventional concrete materials preferred in most field practices, ECC, which has reinforcing microfibers smaller than human hair, is relatively ductile in tension. Ductility is a direct result of strain-hardening response due to the formation of multiple closely spaced microcracks with average widths of less than 100 micrometers. Even under excessive loading conditions, crack widths reportedly remain constant.

“Having cracks with widths at micrometer levels allows us to add special attributes such as self-healing to ECC material,” said Mustafa Sahmaran, professor of civil engineering and director of the Advanced Infrastructure Materials Research Laboratory at Gazi University, Ankara, Turkey.

The concept of self-healing materials isn’t new, however, there’s been a recent interest in the technology of these materials due to the deteriorating infrastructures found around the world.

Sahmaran says that the process of self-healing in ECC materials is quite straightforward. Cracks heal themselves with the help of two main mechanisms: ongoing hydration reactions of anhydrous cementitious materials resulting in further calcium-silicate-hydrate gels and calcium carbonate precipitation. What is needed for these two reactions to take place is abundantly available for structures located anywhere in the world: water and air.

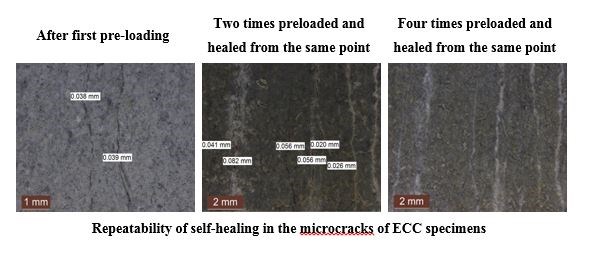

“Despite the effectiveness of self-healing in ECCs with micron-size cracks, some critics question the ‘robustness’ of the mechanism,” he said. “One such robustness criterion is the ‘repeatability,’ or multiple reoccurrence of crack closure. The other criterion is the ‘pervasiveness, meaning that the mechanism should take place all over the structural element rather than being restricted to certain areas.”

Sahmaran and his lab team, in cooperation with Mohamed Lachemi from Ryerson University in Canada sought an answer to the question of robustness of the self-healing mechanism in ECCs. The verdict? They believe they can prove the relatively high robustness of self-healing in ECC.

“Even after six repetitive pre-cracking occurrences from the exact same place, each one almost causing specimen failure, ECC material can recover by 85% depending on the test method utilized in the evaluation of self-healing rate,” said Gurkan Yildirim, research assistant and Ph.D. candidate in civil engineering at Gazi University. “Self-healing rates recorded from different sections of specimens also confirm that results are very close to each other, meaning that the mechanism is rather pervasive. On top of that, ECC material does not sacrifice the intrinsic tight microcracking behavior, so that after the application of pre-cracking from the same place up to nine repetitive times, maximum crack width is restricted to a 190 micrometer level, which also leads to superior durability characteristics, even under harsh environmental conditions.”

The researchers say that with its inherent tight microcracking and self-healing behavior, ECC could become the material solution to many mechanical and durability property challenges and can help prolong infrastructure functionalization.

The team's research appeared in a paper entitled “Repeatability and Pervasiveness of Self-Healing in Engineered Cementitious Composites,” which was published by the ACI Materials Journal.

Related Content

Thermoplastic composites welding advances for more sustainable airframes

Multiple demonstrators help various welding technologies approach TRL 6 in the quest for lighter weight, lower cost.

Read MoreWhy aren't composites synonymous with infrastructure?

The U.S. seems poised to invest heavily in infrastructure. Can the composites industry rise to the occasion?

Read MoreMaterials & Processes: Composites fibers and resins

Compared to legacy materials like steel, aluminum, iron and titanium, composites are still coming of age, and only just now are being better understood by design and manufacturing engineers. However, composites’ physical properties — combined with unbeatable light weight — make them undeniably attractive.

Read MoreMaterials & Processes: Resin matrices for composites

The matrix binds the fiber reinforcement, gives the composite component its shape and determines its surface quality. A composite matrix may be a polymer, ceramic, metal or carbon. Here’s a guide to selection.

Read MoreRead Next

Composites end markets: Energy (2024)

Composites are used widely in oil/gas, wind and other renewable energy applications. Despite market challenges, growth potential and innovation for composites continue.

Read MoreFrom the CW Archives: The tale of the thermoplastic cryotank

In 2006, guest columnist Bob Hartunian related the story of his efforts two decades prior, while at McDonnell Douglas, to develop a thermoplastic composite crytank for hydrogen storage. He learned a lot of lessons.

Read MoreCW’s 2024 Top Shops survey offers new approach to benchmarking

Respondents that complete the survey by April 30, 2024, have the chance to be recognized as an honoree.

Read More

.jpg;maxWidth=300;quality=90)