Arburg ‘Technology Days’-6700 Visitors and Several Novelties

The first metal-powder injection molded smartphone frame, PP-IML containers molded in under 2 sec, a new additive-manufacturing development center, and hints of innovations yet to come.

Those were just some of the attractions at the annual Technology Days exhibition hosted by Arburg at its headquarters in Lossburg, Germany.

Arburg (U.S. office in Rocky Hill, Conn.) has hosted these events each year since 1999. What Arburg called “the biggest in-house event in the industry” attracted more than 6700 guests from 53 countries, including around 170 from North America and 125 from China.

Displays throughout the company’s 1.84-million-ft2 manufacturing plant included more than 50 machinery exhibits in action, highlighting themes such as medical, packaging, electronics, and automotive molding, as well as lightweight structural solutions, LSR, robotics, Industry 4.0 connectivity, individualized production (“mass customization”), additive manufacturing (3D printing), and the company’s ability to supply complete turnkey cells.

Among the novelties presented at this year’s Technology Days were the following:

• Powder injection molding (PIM): What’s said to be the first metal-powder injection molded (MIM) smartphone frame/housing was demonstrated on a hydraulic Allrounder 470 C Golden Edition press (165 tons). A “green” smartphone back was hot-runner molded with a thickness of around 1 mm and length of 136 mm in a cycle time around 55 sec. The material was flow-optimized Catamold 17-4 PH Plus compound from BASF (U.S. office in Budd Lake, N.J.).

“The booming international smartphone market offers huge potential for powder injection molding,” says Hartmut Walcher, PIM expert at Arburg—referring also to ceramic powder molding, examples of which were on display. “This process enables the use of materials such as stainless steel, titanium, and zirconium oxide, and is significantly more cost-effective than machining.” (Arburg is also working on 3D printing with metal and ceramic powders—see below.)

• High-speed in-mold labeling (IML): Four PP ice-cream cups were molded with IML in 1.8-1.95 sec on a Hidrive P (packaging version) 570 H hybrid press with accumulator-assisted injection. The tubs were only 0.35-mm thick, which is about the lower limit of practicality, according to a representative of Brink B.V. of the Netherlands, which supplied the mold, side-entry robot, and gripper technology.

(Interestingly, Brink also supplied the mold and automation for a four-cavity PP cup molding demo at K 2016 by Sumitomo (SHI) Demag—U.S. office in Strongsville, Ohio—which claimed a 1.75-sec cycle time.)

• Liquid silicone rubber (LSR): Arburg showed two examples of LSR-on-LSR two-component molding, one of them using a press with two injectors, but the other using only a single injector and a cleverly engineered side stream for injecting the second color (also shown at K 2016 in cooperation with Momentive Performance Materials, Waterford, N.Y.; see February Starting Up).

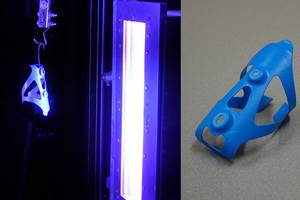

In cooperation with the University of Kassel, Germany, Arburg demonstrated for the first time how UV activation can improve adhesion of LSR to PC. An electric Allrounder 370 overmolded PC inserts, which were UV activated directly in the gripper with LSR to product specimens for adhesion-strength testing.

• Lightweight structural parts: Technology Days included three lightweight molding exhibits. Two involved microcellular foam molding, with either the MuCell process from Trexel Inc., Wilmington, Mass., or Arburg’s own, relatively new Profoam process for impregnating pellets with nitrogen gas in a pressurized hopper. The latter used the new 5-liter hopper suitable for larger parts, which was introduced at K 2016. Arburg said one advantage for Profoam over MuCell is that it utilizes a standard screw with no gas-mixing section, which results in less breakage of reinforcing fibers.

Arburg also demonstrated its Fiber Direct Compounding (FDC) process of introducing continuous glass rovings into the melt in the injection barrel. PP cable-drive housings for car windows were molded in this fashion. Arburg claims they have impact resistance, strength, and rigidity similar to housings made of more expensive PBT, but are up to 30% lighter.

• ‘Smart Service’: As part of its emphasis on Industry 4.0 (see more below), Arburg presented its new remote-maintenance tool for online support. The injection machine is equipped with a router and integrated firewall that permits an encrypted data connection once enabled by the machine operator.

• Additive manufacturing: Arburg presented eight exhibits of its Freeformer 3D printer. Five of them were housed in the new Arburg Prototyping Center, available for customer trials. Each machine is dedicated to a particular material in order to avoid several hours of cleaning for changeovers.

Parts made at the Technology Days included medical-grade PLA surgical implants that are customized for each patient and resorbed by the body after a defined period of time. There was also a functional part made from a PC approved for aerospace injection molding; electrical connectors of flame-retardant PC/ABS; and a mobile-phone cover of nylon that showed how optimizing process parameters can improve surface quality.

News in this technology includes a new support material that will become available in May. It will be soluble in sodium hydroxide, heat stable, easy to process, and providing excellent edge definition in relation to the build material.

A number of other working exhibits reprised demonstrations seen at the K 2016 and Fakuma 2015 shows. One prominent example was Arburg’s new Allrounder 1120 H hybrid press—it’s largest ever—with 650-metric-ton (716.5 U.S.) clamp and brand-new Gestica controller, assisted by the new Multilift V 40 linear robot with payload capacity of 40 kg (88 lb).

Three or four of these presses are in beta testing at customers, and Arburg anticipates full commercialization in 2018. The company also plans to gradually extend the new gesture-enabled Gestica controller to additional machine models, starting at the Fakuma show this October. Meanwhile, the company will continue offering its Selogica control to meet market demand, but will give it an update and facelift in the foreseeable future.

Batch Size of One

Another example from K 2016 was Arburg’s most elaborate example yet of individualized production with a batch size of one, showing off its Industry 4.0 capabilities for linking multiple machines, a remote central-computer database, and “cloud”-based internet communications. An integrated cell injection molded two ABS half-shells of a “smart” luggage tag. A robot then inserts an NFC (near-field communications) chip into one of the shells, so that the part itself becomes a data carrier, identifying itself at the various stations and controlling its production process. Each luggage tag is also assigned its own website in the cloud. At an input terminal an individual user enters personal information and selects a graphic motif from a menu of choices for the design of the tag. This information is programmed into the NFC chip in the luggage tag. At a laser-marking station, user informations (name, address, phone number) are imprinted on the tag in plain text and a QR code. Then, the tag is passed to a pair of Arburg Freeformer 3D printers, which apply the selected graphic motif in two colors. Finally, visitors learn how they can use the smart luggage tag to execute data-supported actions like online ordering of brochures using the integrated NFC chip. Also, the user contact info can be read out using the QR code or NFC chip via smartphone. This includes the individual URL address of the website for the tag, enabling all process and quality data to be accessed from the Arburg host computer (ALS) for 100% product traceability.

This wasn’t the only product individualization/Industry 4.0 demo at the Arburg event. In the exhibit area dedicated to turnkey cells, one cell produced customized hand-strengthening devices. A visitor’s hand strength was first measured and assigned to one of three gripping-force levels. Each level corresponded to a pre-molded acetal spring element containing 5%, 12.5%, or 20% fiberglass for different degrees of stiffness. The visitor was given a QR code to initiate his/her molding order. A robot removed two acetal spring elements with the appropriate stiffness level from a drawer system and inserted them in the two-cavity mold. After overmolding with a TPU grip pad, the two pieces were assembled manually.

If anyone wonders about the practical value of such trade-show style demonstrations of individualized production, Arburg officials report that customers are actively investigating the real-world commercial potential of this concept. Household appliances is one particular area of interest. Another is personalized medical implants. Industry examples (not involving Arburg) include personalized Coca-Cola bottles and Kellogg cereal spoons.

Related Content

Colored carbon fiber composite bike wheels launched at The Cycle Show

Wheel brand Parcours reveals composite bike wheels using Hypetex colored carbon fiber to achieve aesthetic, lightweight and performance goals.

Read MoreJEC World 2022, Part 2: Recycling, natural fibers and additive manufacturing

CW associate editor Hannah Mason recaps several technologies seen on display at JEC World 2022, including new developments from Bcomp, Massivit 3D, Gen 2 Carbon and more.

Read MoreDigital Demo: UV-Cured Powder Coating on Carbon Fiber

Keyland Polymer's R&D chemist will demonstrate the UV powder coating application process followed by UV curing on a carbon fiber water bottle holder. (Sponsored)

Read MoreTwo-time F1 champion Fernando Alonso, SimplyEV debut Kimoa e-bike at Miami Grand Prix

The Formula One driver’s sustainable mobility Kimoa brand is debuting its fully customizable carbon fiber e-bike powered by 3D printing firm Arevo.

Read MoreRead Next

Composites end markets: Energy (2024)

Composites are used widely in oil/gas, wind and other renewable energy applications. Despite market challenges, growth potential and innovation for composites continue.

Read MoreFrom the CW Archives: The tale of the thermoplastic cryotank

In 2006, guest columnist Bob Hartunian related the story of his efforts two decades prior, while at McDonnell Douglas, to develop a thermoplastic composite crytank for hydrogen storage. He learned a lot of lessons.

Read MoreCW’s 2024 Top Shops survey offers new approach to benchmarking

Respondents that complete the survey by April 30, 2024, have the chance to be recognized as an honoree.

Read More