Turnkey manufacturing systems: Aiming for automotive-industry volume production

Fives Cincinnati (Hebron, KY, US) has announced an integrated manufacturing system for automotive composites comprising two automated manufacturing cells.

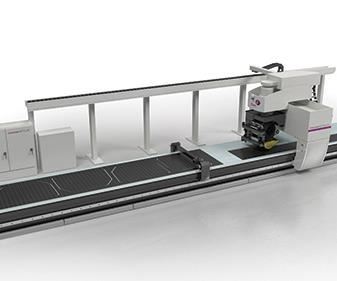

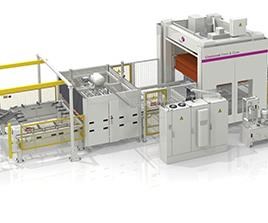

Fives Cincinnati (Hebron, KY, US) has announced an integrated system for automotive composites comprising two automated manufacturing cells: a tape layer with integrated ply cutters that provides near net-shaped and kitted material stacks, and a form-and-cure cell in which a conveyor receives and places the kitted stacks into a compression forming press supplied by technology development partner Continental Structural Plastics (Auburn Hills, MI, US). According to chief technology officer Yannick Leprêtre, this thermoforming process is being developed with a US automotive supplier for continuous fiber-reinforced composites for structural applications. “We are transferring our aerospace technology into automotive,” says Leprêtre.

Fives director of product strategy and development Dan Allman details, “The first step is to make a flat charge using one of our automated tape laying or fiber placement machines. Our goal is to go directly from 2D charge to 3D part in one step, but some parts, due to their complex geometry, require preforming first.” The preform is then moved into a curing mold. The system is designed to support thermoset or thermoplastic polymers. “We have demonstrated under 3-minute cycle times to produce a 2D thermoset charge, and are targeting 90 seconds, utilizing an automated fiber placement process that minimizes waste to less than 5%,” says Allman. He notes the form-and-cure process has a 4-minute cycle time with epoxies, which drops to 90 seconds for some of the new, innovative polymers based on a 1-minute cure. “For thermoplastics, we can easily achieve cycle times under 90 seconds for automotive applications,” Allman adds.

Demonstrations have primarily used unidirectional tapes and tows in glass and carbon fiber but have also used woven materials and non-crimp fabrics. “This is a very flexible system,” claims Allman, “and automation is tailored per production volume.”

He points out that high-volume applications require highly automated systems that provide repeatable, rapid cycle-time capability in order to maximize the output and return on investment of the equipment assets. “We have moved well beyond the semi-automated, labor-intensive and long cycle-time solutions of yesterday,” says Allman.

This short article is a Side Story to a feature article titled "Turnkey manufacturing systems: Materials, markets & maturation."

Related Content

-

Manufacturing the MFFD thermoplastic composite fuselage

Demonstrator’s upper, lower shells and assembly prove materials and new processes for lighter, cheaper and more sustainable high-rate future aircraft.

-

Thermoplastic composites welding advances for more sustainable airframes

Multiple demonstrators help various welding technologies approach TRL 6 in the quest for lighter weight, lower cost.

-

PEEK vs. PEKK vs. PAEK and continuous compression molding

Suppliers of thermoplastics and carbon fiber chime in regarding PEEK vs. PEKK, and now PAEK, as well as in-situ consolidation — the supply chain for thermoplastic tape composites continues to evolve.