Materials & Processes: Resin matrices for composites

The matrix binds the fiber reinforcement, gives the composite component its shape and determines its surface quality. A composite matrix may be a polymer, ceramic, metal or carbon. Here’s a guide to selection.

- Wind/Energy

- Sustainability

- Automotive

- Sheet Molding Compound

- Defense

- Biomaterials

- Out of Autoclave

- Market Outlook

- Materials

- Pressure Vessels

- Adhesives

- Infrastructure

- Consumer

- Epoxies

- Resins

- Thermoplastics

- Aerospace

- Mass Transit

- Reinforcements

- Markets

- Marine

- Autoclave

- Construction

- Hi-Temp Resins

- Ketones

- Prepregs

- Composites Basics

- RTM

- Medical

- BMI

The matrix binds the fiber reinforcement, transfers loads between fibers, gives the composite component its net shape and determines its surface quality. A composite matrix may be a polymer, ceramic, metal or carbon. Polymer matrices are the most widely used for composites in commercial and high-performance aerospace applications. Ceramic and metal matrices are typically used in very high-temperature environments, such as engines. Carbon as a matrix is used in extreme high-temperature applications, such as carbon/carbon brakes and rocket nozzles.

Resin matrices: Thermosets

The polymers most widely used in composites are thermosets, a class of plastic resins that, when cured by thermal and/or chemical (catalyst or promoter) or other means, become substantially infusible and insoluble. After cure, a thermoset cannot be returned to its uncured state. Although almost all thermosets in commercial use today are derived from petroleum feedstocks, R&D and commercialization is ongoing in the growing field of bio-resins. Developed primarily in an effort to use renewable agricultural feedstocks, bio-resins comprise, in varying proportions, polyol (from soybeans) and ethanol (from corn).

Unsaturated polyester resins are the most widely used thermosets in commercial, mass-production applications, thanks to their ease of handling, good balance of mechanical, electrical and chemical properties, and relatively low cost. (Saturated polyesters are thermoplastic polymers.) Typically coupled with glass fiber reinforcements, polyesters adapt well to a range of fabrication processes and are most commonly used in open-mold sprayup, compression molding, resin transfer molding (RTM) and casting. Polyesters provide the primary resin matrix used in bulk molding compounds (BMC) and sheet molding compounds (SMC), which are processed using compression molding (see "Fabrication methods,").

The properties of polyester formulations can be modified to meet specific performance criteria, based on the selection of glycol and acid elements and reactive monomers (most commonly, styrene). Styrene is added in amounts up to 50% to reduce viscosity, making the resin easier to handle and process. Polyester resins are often differentiated in terms of their base ingredients. Orthopolyesters, for example, build on orthophthalic acid. Isopolyester resins have isophthalic acid as their essential ingredient and exhibit superior chemical and thermal resistance, compared to orthopolyesters. Terephthalic polyester resins incorporate terephthalic acids and have been formulated for improved toughness, compared to conventional isopolyesters. Dicyclopentadiene (DCPD)-modifed polyesters. can have lower viscosity and provide good properties at lower styrene content. However, DCPD solidifies at room temperature and, therefore, requires heated storage and handling facilities.

Styrene enables polyester resins to cure from a liquid to a solid by crosslinking the molecular chains. However, polyester resins will gel on their own over a long period of time. Thus, small amounts of inhibitor are often added during resin manufacture to slow this action and increase the resin’s shelf life. Even without inhibitors, polyester’s rate of polymerization is too slow to make it practical, as-is, for composite molding, so catalysts and accelerators are added to speed cure. Catalysts are added to the resin prior to molding, to activate crosslinking, but do not take part in the polymerization reaction. Catalysts used with polyester include Methyl ethyl ketone peroxide (MEKP) and peroxide. Thorough mixing is important, and the ratio of catalyst to resin weight affects cure rate and, potentially, the degree of cure. For example, 1% is typically considered a slow mix, 2% is a common supplier specification, and 3% would be a fast curing mix. Adding more than 4% catalyst by weight, however, might result in a failure to cure.

An accelerator is added to the catalyzed resin to enable the reaction to proceed at workshop temperature and/or at a greater rate. Because accelerators have little influence on the resin in the absence of a catalyst, they are sometimes added to the resin by the polyester manufacturer to create a pre-accelerated resin. Cobalt is a common accelerator. Cure is exothermic: as the components crosslink, they release heat. Fabricators can control the cure profile in terms of shelf life, pot life (the time prior to cure), gel time, cure temperature and viscosity through careful formulation of the catalyst package, which might include accelerators but also inhibitors and promoters.

A wide array of other additives — sometimes known as modifiers — offer embellished processing or performance attributes. The most common are pigments, fillers and flame or fire retardants. Although pigments are only added at about 3% of resin weight, their use can affect curing and degrade the final laminate if they are incompatible with the resin. Fillers, such as milled fiber, chopped fiber and glass microspheres are often added in quantities up to 50% to help reduce cost, facilitate molding or prevent exotherm in thick laminates. Certain fillers also can contribute to fire-resistance in the finished composite.

Halogen-free flame retardants are being developed because halogens (i.e., bromine, which, along with fluorine, chlorine, iodine and astatine, occupy Group VIIA of the periodic table) are known to release toxic and corrosive gases when exposed to flame. Alumina trihydrate (ATH) is one alternative used in MoldX products by Huber Engineered Materials (Atlanta, GA, US). Huber’s ATH products reportedly enable higher loadings without a change in viscosity for excellent mold flow and significantly reduce halogen-containing fire retardants without sacrificing flame retardant properties. R.J. Marshall Co. (Southfield, MI, US) has developed its Maxfil product line, with three ATH grades that offer different particle sizes as well as blends of ATH and calcium carbonate for applications where flame retardance and smoke suppression are not as critical, such as BMC/SMC sprayup of wall panels for bathrooms and pultruded pipe for oil platforms.

Specially formulated, unreinforced polyester resins, known as gel coats, improve the impact and abrasion resistance and the surface appearance of the final product. These are applied to a mold surface and gelled before layup of the composite. In the tub and shower market, for example, gel-coated fiberglass products have been dominant, and their use continues to grow, despite strong competition from glass/acrylic units made with polymethyl methacrylate (PMMA). HK Research Corp. (Hickory, NC, US) has developed its REVOLUTION series, which boasts a grafted polymer matrix with a tighter network, offering a truly flexible gel coat with increased weather resistance while maintaining ease of application and pricing on par with traditional gel coats. Recent additions to this product line include the High Definition EXTREME “METAL FLEX” in-mold system, which enables boatbuilders to add a ‘metallic’ coating to their fiberglass parts that compares to the popular automotive paints. The company claims it can “match any color combination imaginable,” having already done so with 2014 automotive colors for several boatbuilders.

Ashland Performance Materials (Dublin, OH, US) is one resin supplier making significant effort to commercialize bio-based resins in this arena with its ENVIREZ line, which replaces glycol, derived from crude oil, with bio-glycol derived from corn or soybeans. Canada’s Campion Marine (Kelowna, BC) is the first volume boatbuilder to convert to a bio-resin, using Ashland’s special laminating grade Envirez L 86300 in all of its models since 2009, after tests verified that it had strength equal to, and elongation and elasticity superior to, the petroleum-based polyesters used previously. Reichhold LLC2 (Research Triangle Park, NC, US) also has developed a bio-resin, POLYLITE 31325-00, a low-viscosity unsaturated polyester with 25% soy oil content. The material is designed for SMC/BMC applications. Dow Chemical Co. Pasadena, TX, US) formulates bio-based unsaturated polyesters (ortho-, iso-, and terephthalic, DCPD-modified and bisphenol A fumerate) and vinyl esters using a methacrylated fatty acid (MFA) as its reactive diluent, which is a partial styrene replacement derived from palm kernel and coconut oil. Applied in 15-18% loadings, MFA reduces styrene emissions up to 27%, with good toughness and elongation, low-to-no odor and 60% bio-content. AOC Resins (Collierville, TN, US) offers the EkoTek line of UPRs that uses feedstocks derived from soy and corn, and one product, H431-AKAG, has up to 42% renewable and/or recycled content. Dixie Chemical Co. Inc. (Pasadena, TX, US) offers two lines of unsaturated polyesters, MAESO and MAELO, based on soybean oil and linseed oil feedstocks, respectively. While epoxidized linseed and soy oils have been around for years, Dixie’s versions are functionalized with maleic anhydride and other chemistries to incorporate reactive sites. The resins have properties comparable to typical UPRs, and like conventional resin systems, contain a reactive diluent, such as styrene, vinyl toluene or Dixie’s bio-based methacrylated fatty acid (MFA)

Vinyl ester resins offer a bridge between lower-cost, rapid-curing and easily processed polyesters and higher-performance epoxy resins (described below). Their molecular structure is very similar to polyester’s, but they have reactive sites only at the ends of the molecular chains and have fewer ester groups. Because ester groups are susceptible to hydrolysis, having fewer of them increases vinyl esters’ resistance to water and chemically corrosive environments, which accounts, in part, for their higher price. Vinyl esters are favored in chemical tanks and other applications for which corrosion resistance is key goal, and they also add value in structural laminates that require a high degree of moisture resistance (such as boat hulls and decks). They are processed and cure very similarly to polyesters, with the potential to offer improved toughness, though this usually requires an elevated temperature post-cure.

For advanced composite matrices, the most common thermosets are epoxies, phenolics, cyanate esters (CEs), bismaleimides (BMIs), benzoxazines and polyimides.

Epoxy resins contribute strength, durability and chemical resistance to a composite. They offer high performance at elevated temperatures, with hot/wet service temperatures up to 121°C. Epoxies come in liquid, solid and semisolid forms and typically cure by reaction with amines or anhydrides. Most commercial epoxies have a chemical structure based on diglycidyl ether of bisphenol A, diglycidyl ether of bisphenol F (lower viscosity), creosol novolacs, or phenolic novolacs. Epoxies are not cured with a catalyst, like polyester resins, but instead use a hardener (also called a curing agent). The hardener (part B) and the base resin (part A) co-react in an ‘addition reaction,’ according to a fixed ratio. Thus, it is critical to use the correct mix ratio of resin to hardener in order to ensure a complete reaction. Otherwise, the resin will neither fully cure nor attain its full properties. (Meter/mix/dispense equipment is used widely now to automate and accurately control this mixing of resin and then deliver it into the molding process.) The type of hardener used affects the final properties of the cured resin, and thus, the composite. Hardeners include aliphatic amines, cycloaliphatic amines, polyamides, aromatic amines, anhydrides, phenols, thiols and latent hardeners (e.g., Lewis acids). Many aerospace applications use amine-cured, multifunctional epoxies that require cure at elevated temperatures and pressures. Toughened epoxy — with thermoplastics and reactive rubber compounds added to counteract brittleness due to high degree of crosslinking — have become the norm in high percentage composite airframes, such as The Boeing Co.’s (Chicago, IL, US) 787 Dreamliner and the Airbus (Toulouse, France) A350 XWB.

A notable development on the epoxy front, powered in large part by the automotive industry's enduring expectation of "part-per-minute" production, has been the advent of a group of new resin formulations that have acquired the apt descriptor "snap-cure" epoxies. It's the collective term for resins designed with an out-life similar to conventional epoxies, which can be prolonged until fibers are thoroughly impregnated, but then, at a "trigger" temperature, can be activated to a cure cycle with a duration of two minutes or less.

Dow Automotive Systems (Horgen, Switzerland) introduced its VORAFORCE fast-cure automotive epoxy infusion resin platform in 2014. It offers cure time as fast as 30 seconds, and the resin’s latency characteristics coupled with low viscosity (as low as 10 MPa/sec), maximizes infusion speed.

Hexion Inc. (Columbus, OH, US) has offered a range of optimized fast-cure epoxies, curing agents and preform binders. Hexion’s trademarked Epikote Resin TRAC 06170 with Epikure curing agent TRAC 06170 are targeted to structural parts made using RTM or wet compression molding. The combination reportedly results in a part-to-part cycle time of less than 1 minute, depending on part size and complexity. The Epikote Resin TRAC 06400 series is available for fast-cure prepregs as well, with cure times as short as 90 seconds, he adds, when cured at 130°C.

Hexcel (Stamford, CT, US) offers a snap-cure prepreg, trademarked HexPly M77, that has a two-minute cycle at 150°C (80 bar pressure) for a 5-mm-thick part. The low tack of HexPly M77 enables the prepreg to be cut into precise shapes by laser cutter, then robotically oriented, assembled and consolidated into flat preforms. Its Tg of 125°C enables demolding of cured parts while hot for a faster production cycle. Cytec Solvay (Heanor, Derbyshire, UK), reported that an 18-month R&D program there has resulted in several sub-3-minute-cure epoxy resin chemistries for primary and secondary vehicle body-in-white structures. Bio-based epoxies are also being developed by a number of firms. One is Sicomin (Chateauneuf les Martigues, France) that has developed several trademarked GreenPoxy resins for a decade. SR GreenPoxy 56 is a clear epoxy with more than 50% carbon content derived from plant and vegetable sources, while Surf Clear EVO is an epoxy dedicated to the surfboard market. The company won’t identify exact plant sources for its resin, and Sicomin’s export manager Marc Denjean says that its epoxies can be combined with a wide selection of hardeners (non-bio-based) to match specific processes, including hand layup, infusion, compression molding, or others. Entropy Resins (Hayward, CA, US) claims to have the industry’s first US Department of Agriculture (USDA) “bio-preferred”-certified epoxy, Super Sap Epoxy 100/1000, with 37% of its molecular backbone derived from naturally occurring pine oil. Entropy claims the resin adheres well to reinforcements and has better elongation properties than petroleum-based epoxies.

Huntsman Advanced Materials (The Woodlands, TX, US) has worked for the past eight years with BMW on its i3 production car program, which uses Huntsman’s trademarked Araldite LY 3585 epoxy resin, coupled with Aradur 3475 hardener in a high-pressure RTM process (see “BMW Leipzig: The epicenter of i3 production,").

Phenolic resins are based on a combination of an aromatic alcohol and an aldehyde, such as phenol, combined with formaldehyde. They find application in flame-resistant aircraft interior panels and in commercial markets that require low-cost, flame-resistant and low-smoke products. Excellent char yield and ablative (heat-absorbing) characteristics have made phenolics long-time favorites for ablative and rocket nozzle applications. They also have proven to be successful in nonaerospace applications, notably in components for offshore oil and gas platforms, and in mass transit and electronics applications. However, phenolics polymerize by means of a condensation reaction, which causes the release of water vapor and formaldehyde during cure. This phenomenon can produce voids in the composite. As a result, phenolics’ mechanical properties are somewhat lower than those of epoxies and most other high-performance resins. Further, molds must be designed with adequate venting and/or the molding process must include a “breathe” step to allow the water vapor to escape. For that reason, phenolics are not typically processed using RTM.

Cyanate esters (CEs) are versatile matrices that provide excellent strength and toughness, allow very low moisture absorption and possess superior electrical properties compared to other polymer matrices, although these benefits come at a higher cost. CEs feature hot/wet service temperatures to 149°C and are usually toughened with thermoplastics or spherical rubber particles. They process similarly to epoxies, but their curing process is simpler, thanks to CE’s viscosity profile and nominal volatiles. Current applications range from radomes, antennae, missiles and ablatives to microelectronics and microwave products.

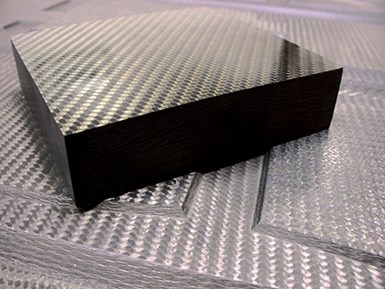

Bismaleimide (BMI) resins are challenging epoxies in aeropause applications. Previously, BMI was thought to be too expensive, but now can be processed at the same cost as high-performance epoxy resins and runs about US$75/lb for carbon fiber/BMI prepreg compared to $70/lb for intermediate-modulus carbon fiber/epoxy prepreg. This 16-ply, 6K carbon fiber fabric, OOA-cured tool was made from Cytec Solvay's (Tempe, AZ, US) HTM520 BMI tooling prepreg. As the image demonstrates, the finished tool presents a good surface finish and, Cytec Solvay reports, the through-thickness quality necessary for the application. But BMI's use is driven not just by tooling and applications where service temperatures exceed 177°C, but also by the increasing use of composites in structures that need improved hot/wet and open-hole compression performance at moderate temperatures (80-120°C). Source: Cytec Solvay

Among the more exotic of resins, bismaleimides and polyimides (close relatives, chemically) are used in high-temperature applications on aircraft and missiles (e.g., for jet engine nacelle components). BMIs offer hot/wet service temperatures (to 232°C), while some polyimides can be used to 371°C for short periods of time. Volatiles and moisture emitted during cure make polyimides more difficult to work with than epoxies or CEs; special formulation and processing techniques have been developed to reduce or eliminate voids and delamination. Both BMIs and polyimides have traditionally exhibited higher moisture absorption and lower toughness values than CEs and epoxies, but significant progress has been made in recent years to create tougher formulations, and BMIs are now touted as having better resistance to fluid ingression than epoxies. Increased use of BMI is being driven not just by tooling and applications where service temperatures exceed 177°C, but also by the increasing use of composites in structures that need improved hot/wet and open hole compression (OHC) performance at moderate temperatures, e.g., 80°C to 120°C. This is the reason behind much of its use on the F-35 Lightning II, enabling damage-tolerant structures at lower mass vs. epoxy. OEMs continue to beat the drum for resins with at least a 20 percent increase in OHC vs. the toughened epoxies being used on the 787 and A350. Previously, BMI was thought to be too expensive, but at US$75/lb for carbon fiber prepreg it competes very well with intermediate-modulus (IM) carbon fiber/epoxy systems at US$70/lb, and previous issues with long cycle times are also being addressed.

Polybutadiene resins offer good electrical properties and chemical resistance and have been used successfully as alternatives to epoxy in E-glass/epoxy composites typically used to mold thin-walled, glass-reinforced radomes.

More recently developed than BMI, benzoxazine resins are begin trialed for for autoclavable tooling. Airtech International’s (Huntington Beach, CA, US) Beta Prepreg autoclave-cure benzoxazine tooling system, for example, offers a 218°C service temperature, low resin shrinkage for improved dimensional stability, reduced springback and room temperature storage. Further, benzoxazines, like epoxies, can be used in infusion processes, and exhibit high stiffness, excellent thermal properties (they have high Tg), lower moisture absorption and better flammability resistance (high char yield) than epoxies. Benzoxazines reprtedly also have better resistance to ultraviolet radiation than epoxies. Source: Airtech International

Benzoxazines are formed by reacting phenol, formaldehyde and amine in an additive reaction with ring opening polymerization which produces a high molecular weight polymer with near-zero cure shrinkage, reactive sites that greatly facilitate hybridizing with other resins, and the ability to polymerize with itself (homopolymerize) to form polybenzoxazine networks very similar to phenolic. Discovered in the 1940s, benzoxazine development intensified during the 1980s and 90s, and were qualified into printed circuit boards (PCBs) in 2000, yet systems for structural composites weren’t commercialized until 2008. Interest in benzoxazines is increasing due to its high stiffness, excellent thermal properties, lower moisture absorption, better resistance to flammability and also to ultraviolet (UV) radiation than epoxies. The more exotic benzoxazines can have a Tg as high as 300°C to 350°C; more common formulations range between 150°C and 250°C. Like BMI, these higher-Tg systems can be brittle and need to be toughened to prevent microcracking. Suppliers claim that they can be processed in much the same way same as epoxies but with a lower heat reaction. Henkel Aerospace (Bay Point, CA, US reports that a 19mm thick, 150-ply laminate can be cured with a 5°C/min ramp rate without an uncontrolled exotherm.

Benzoxazine has a price point and achieves performance between that of epoxy and BMI. How it is presented to the potential user varies, however, based on the very different approaches taken by its two leading suppliers. Henkel — supplying structural prepregs, infusion resins and film adhesives, while partnering with Airtech International Inc. (Huntington Beach, CA, US) to offer tooling prepreg — sees benzoxazine as a way to cut the cost of composite structures throughout the supply chain due to its room-temperature stability (no frozen storage) and processing advantages, satisfying not just complex structural demands, but also supply, handling, surface finish and health and safety requirements. Meanwhile, Huntsman Advanced Materials (Basel, Switzerland and The Woodlands, TX, US) is selling benzoxazine building block components to prepreggers, resin formulators and adhesives manufacturers. It views benzoxazine’s unique and almost endless ability to hybridize with other resins — e.g. epoxy, phenolic, BMI, thiol and more — as the path to achieving truly tailored polymers that will meet the needs of individual composite applications and even further optimized structural designs in the future. Offering the flammability, smoke and toxicity (FST) performance of phenolic without its voids and processing difficulties, benzoxazine seems poised to push large, integrated structures into aircraft and other transportation interiors. But some users caution that it has not yet attained the maturity of BMI and still requiring further development in several areas, including OOA processing.

Nonetheless, benzoxazine has been adopted by a major airframe manufacturer for bonding large BMI tooling assemblies via Airtech’s Beta 8610 film adhesive, and also qualified for the Airbus A380 auxiliary power unit (APU) housing, replacing the original BMI with a Henkel benzoxazine prepreg, reinforced with Toho Tenax (Tokyo, Japan) carbon fiber. Airtech’s Beta Prepreg autoclave-cure tooling system, built on Henkel’s benzoxazine resin, has been used at GKN Aerospace Munich for production of 100 carbon fiber T-stringer support tools used in manufacturing the Airbus A350’s inboard and outboard wing flaps.

Another, but less well-known resin class is phthalonitriles, originally developed by the U.S. Naval Research Laboratory for very high-temperature applications. Commercialized by Eikos (Franklin, MA, US) phthalonitriles have service temperatures approaching 371°C and have been selected for high-temperature engine parts as well as submarine vessels.

Resin matrices: Thermoplastic

In contrast to crosslinking thermosets, whose cure reaction cannot be reversed, thermoplastics harden when cooled but retain their plasticity; that is, they will remelt and can be reshaped by reheating them above their processing temperature. Less-expensive thermoplastic matrices offer lower processing temperatures but also have limited use temperatures. They draw from the menu of both engineered and commodity plastics, such as polyethylene (PE), polyethylene terephthalate (PET), polybutylene terephthalate (PBT), polycarbonate (PC), acrylonitrile butadiene styrene (ABS), polyamide (PA or nylon) and polypropylene (PP). High-volume commercial products, such as athletic footwear, orthotics and medical prostheses, benefit from the toughness and moisture resistance of these resins, as do automotive air intake manifolds and other underhood parts.

High-performance thermoplastic resins — polyetheretherketone (PEEK), polyetherketone (PEK), polyamide-imide (PAI), polyarylsulfone (PAS), polyetherimide (PEI), polyethersulfone (PES), polyphenylene sulfide (PPS) and liquid crystal polymer (LCP) — function well in high-temperature environments and, once hardened, neither absorb water nor degrade when exposed to moisture. Reinforced with high-performance fibers, these resins exhibit lengthy prepreg shelf life without refrigeration and possess exceptional impact-resistance and vibration-damping properties. They also offer the opportunity to use recycled content and ease the recycling of waste and end-of-life structures.

However, they can present composites manufacturers with some processing challenges because of their relatively high viscosity. Reinforced thermoplastic composites that feature higher performance resins as matrices are making inroads into aerospace applications. The Airbus A380’s 18m keel beam uses a large number of carbon fiber/PPS ribs and brackets, as do the A340-600 ailerons. Composites Forecasts and Consulting LLC (Mesa, AZ, US) reports that the Boeing 787 family requires 10,000 to 15,000 carbon fiber/PPS clips and cleats per aircraft to help secure exterior skins to composite circular frame sections while the Airbus A350 WXB is believed to use roughly 8,000 per aircraft. Stork Fokker AESP (Hoogeveen, The Netherlands) has supplied carbon/PEI floor panels for the Gulfstream Aerospace (Savannah, GA, US) G550 executive jet, and for the G650, it added CF/PPS rudder and elevators in the aircraft tail. Fokker Aerostructures BV (Papendrecht, The Netherlands) designed and is now manufacturing the CF/PPS horizontal tailplane (HTP) for the AgustaWestland AW169 rotorcraft. Other applications include aircraft seatbacks and floor beams, while research continues to demonstrate automatically tape layed and in-situ-consolidated, stringer-stiffened fuselage panels using CF/PEEK, which require no further heating or pressure.

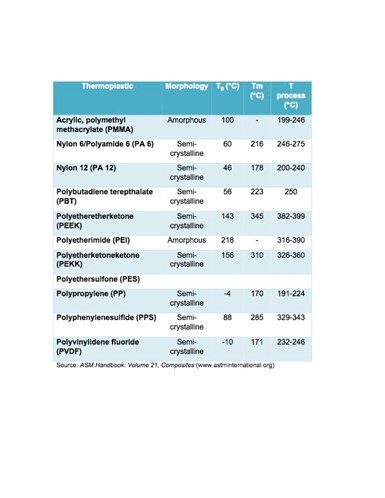

Thermoplastic polymers can be amorphous with randomly arranged molecular chains, or semi-crystalline with both amorphous areas and areas where molecules are packed in a crystal lattice. Amorphous thermoplastics do not form crystalline structure and have a molding/maximum service temperature close to their glass transition temperature (Tg). Semi-crystalline thermoplastics have both a Tg and a melt temperature at which the crystalline structure breaks down. The mechanical properties of parts made with semi-crystalline thermoplastics depend upon the amount of crystallinity, which is determined by the cooling rate used to make the part. Source: CW

Thermoplastic polymers can be amorphous with randomly arranged molecular chains, or semi-crystalline with both amorphous areas and areas where molecules are packed in a crystal lattice. Amorphous thermoplastics do not form crystalline structure and have a molding/maximum service temperature close to their glass transition temperature (Tg). Semi-crystalline thermoplastics have both a Tg and a melt temperature at which the crystalline structure breaks down. The mechanical properties of parts made with semi-crystalline thermoplastics depend upon the amount of crystallinity, which is determined by the cooling rate used to make the part. (See the thermoplastics comparison chart at right.)

In an effort to enable very short cycle time advanced composites for high-volume applications, Aonix Advanced Materials Corp. (Ottawa, ON, Canada) has developed its amorphous Ultra-P, Ultra-S and Ultra-I families of polymers, based on modified paraphenylene, sulfone and polyimide systems to avoid traditional crystalline polymer issues with very sensitive and long cooling cycle and warpage in the final parts. Composites made with Ultra-I matrix systems (modified polyimide) show thermo-mechanical properties that are comparable to PEEK-based composites, while those using Ultra-S matrix systems (modified sulfone) compete head-to-head with conventional epoxy-based composites. Aonix’ customized Express machines are hydraulically operated, modified compression molding and thermoforming units that reportedly can transform a pre-consolidated blank into a part in a 1-min cycle.

Meanwhile, carbon fiber-reinforced nylon (polyamide) has become the composite of choice for small to medium unmanned aerial vehicles (UAVs or drones) and is also popular in sporting goods. Magna Interinational's (Aurora, ON, Canada) Exteriors operating unit is producing the North American automotive industry's first all-thermoplastic, composite, fully recyclable liftgate module for the 2014 Nissan Rogue crossover utility vehicle. The full liftgate assembly is 30% lighter than comparable stamped steel systems, comprised of an outer panel molded from unreinforced thermoplastic olefin (TPO) compound and an inner panel made using 30% long glass fiber/polypropylene (PP).

Resin matrices: Thermoset or thermoplastic

Polyurethane resins are available in both thermoset and thermoplastic formulations. Thermoset polyurethanes are used to pultrude tough parts, such as marine sheet piling and electrical power poles, and to enhance the rigidity of automotive bumper fascias made by reaction injection molding (RIM). For information about RIM, see “Fabrication methods.” Polyurea polymer formulations are available for reinforced reaction injection molding (RRIM), with the mineral wollastonite as reinforcement. They were the first polymers to withstand the high temperatures in automotive painting processes and also provide a Class A finish. Huntsman Polyurethanes (Auburn Hills, MI, US) kicked off the “snap-cure” revolution with its VITROX product. VITROX can remain at a consistently low and stable viscosity until the “kick off” temperature is reached, which activates a snap cure. This trigger temperature is determined by the resin’s catalyst blend and specific formulation, and can be precisely tailored to a customer’s application, with pot life tailorable from <5 minutes to up to several hours, compared to conventional PUR pot life of 20-25 minutes. Designed for infusion, RTM, VARTM and filament winding applications, and targeted at the automotive industry, VITROX offers a Tg of more than 200°C and reportedly has good mechanicals and inherent FST performance.

Also available in either form are polyimides (the thermoset form of which already has been described). In thermoplastic form, polyimide resin readily releases volatiles under heat and pressure, producing parts with fewer voids.

Two other resins have been added to this category in the past decade that, in thermoplastic form, can be processed, like thermosets, at lower viscosities. A class of cyclic thermoplastic polyesters developed originally at General Electric Co. and marketed by Cyclics Corporation (Schenectady, NY, US) offers easier processing. Thermoplastic polyester is broken down into a cyclic oligomer form that, when heated to a specified temperature, drops to a water-like viscosity — a significant aid to fiber wetout. When it is catalyzed and then cooled, the oligomer returns to more conventional viscosity and forms a long-chain, high-molecular-weight thermoplastic. The material offers the properties of a thermoplastic but can be processed like a thermoset. Another example is the family of patented thermoplastic polyurethanes (TPUs) developed around 2000 by Dow Chemical Co. (Midland, MI, US) and spun off in 2004 to Midland-based Fulcrum Composites Inc.. These TPUs have made possible the commercialization of a thermoplastic pultrusion process. Although pultrusion has been dominated by low-viscosity thermosets, the Dow TPUs have the ability to partially depolymerize at their processing temperature and rapidly repolymerize as they cool. In other words, the monomer molecules in the long polymer chains partially unlink as the resin pellets are heated and melted, then relink when cooled. This development has made possible the production of pultruded profiles that can be postformed (via thermoforming) or overmolded (via extrusion and/or injection molding) to create products such as threaded rod, without the use of machining processes that damage the pultruded fibers.

Finally, new hardener technology has been developed for thermoset epoxy resins enabling designed in “cleavage points” so that the resin’s crosslinks break apart and leave thermoplastic molecules that are easy to recycle. Developed by Connora Technologies (Hayward, CA, US) as Recyclamine and marketed as Cleavamine by partner Adesso Advanced Materials (Wu Xi, Jiangsu Province, China), the technology is applicable to any epoxy system and has been demonstrated in systems for room temperature infusion, compression molding, prepreg, RTM and HP-RTM. Cured epoxy composites have been dissolved in a dilute (25%) acetic acid recycling bath at 100°C for one hour, enabling easy removal of carbon fiber and subsequent drying and grinding of the thermoplastic epoxy matrix into a reusable powder.

Out-of-autoclave processing

There has been considerable demand in the aerospace industry for matrix resins that can deliver autoclave-equivalent laminates (including <1% void content) without the need to be cured in autoclaves, which are not only capital intensive but expensive to operate. Recent industry surveys indicate that for part sized from 8m2 to 130m2, ovens can be installed for one-seventh to one-tenth the cost of a comparably sized autoclave, and the cost of dry fiber and liquid resin to make oven-curable versions of he parts can be as much as 70% less than the same materials converted to prepreg.

TenCate Advanced Composites (Morgan Hill, CA, US and Nijverdal, The Netherlands) offers six different out-of-autoclave (OOA) curable epoxy prepregs with Tg ranging from 125°C to 203°C, including TC250 toughened epoxy (with properties in the NCAMP database), TC275 products designed for general aviation use and TC350 toughened high temperature system for use in military and commercial aerospace structures. The latter two are listed as capable of yielding parts with very low (<0.05%) void content. Hexcel’s (Stamford, CT, US) HexPly M56 is a 180˚C-cure epoxy product line for aircraft structures, while Cytec’s OOA products include the following:

- Cycom 5320-1, developed for aircraft primary structure, which cures at 180˚C.

- Cycom 5215 with a wet Tg of more than 150°C after a 177°C freestanding postcure.

- MTM44-1 toughened epoxy with a maximum wet Tg of 150°C (adopted by GE Aviation to manufacture the outer and mid-section fixed trailing edge panels for the Airbus A350 XWB wing).

- MTM46 with a maximum wet Tg of 130°C

- MTM27 with a 15-min cure cycle at 150°C followed by 110°C postcure,

- MTM45 with a maximum wet Tg of 160°C (used throughout the structure on the Advanced Composite Cargo Aircraft (ACCA).

- MTM57-2 reduced tack, vacuum bag only ZPREG, and a wide variety of LTM low temperature tooling materials.

BMIs also have moved out of the autoclave, and OOA systems are commercially available from Cytec Solvay, TenCate, Renegade Materials Corp. (Springsboro, OH, US) and Stratton Composite Solutions (Marietta, GA, US). Hexcel also has an OOA BMI in development.

Other matrices: Carbon, metal and ceramic

Perhaps the most exotic matrix, in part because it is neither thermoset nor thermoplastic, is pyrolized and densified, noncontinuous carbon, which forms the matrix in carbon/carbon (C/C) composites. C/Cs withstand extremely high temperatures — nearly 1650°C, for example, on NASA's Space Shuttle components — and also find use in aircraft and race car braking components, missile engines and exhaust nozzles, which can experience short-term service temperatures as high as 2760°C.

Metals (e.g., aluminum, titanium and magnesium) and ceramics (such as silicon carbide) are used as matrices, as well, for very specialized applications, such as spacecraft components, where minimal CTE and an absence of outgassing are essential. They also are used in engine components, where polymer matrices cannot offer the extremely high temperature resistance that such applications require.

Editor's note: To continue reading articles in "Industry Overivew, Part I: Materials & Processes," you may return to the SourceBook main menu by clicking here.

Related Content

PEEK vs. PEKK vs. PAEK and continuous compression molding

Suppliers of thermoplastics and carbon fiber chime in regarding PEEK vs. PEKK, and now PAEK, as well as in-situ consolidation — the supply chain for thermoplastic tape composites continues to evolve.

Read MoreMaterials & Processes: Fabrication methods

There are numerous methods for fabricating composite components. Selection of a method for a particular part, therefore, will depend on the materials, the part design and end-use or application. Here's a guide to selection.

Read MoreMaterials & Processes: Fibers for composites

The structural properties of composite materials are derived primarily from the fiber reinforcement. Fiber types, their manufacture, their uses and the end-market applications in which they find most use are described.

Read MoreCryo-compressed hydrogen, the best solution for storage and refueling stations?

Cryomotive’s CRYOGAS solution claims the highest storage density, lowest refueling cost and widest operating range without H2 losses while using one-fifth the carbon fiber required in compressed gas tanks.

Read MoreRead Next

BMW Leipzig: The epicenter of i3 production

A glimpse into the inner workings of an automaker at the forefront of serial-production autocomposites.

Read MoreResins for the Hot Zone, Part II: BMIs, CEs, benzoxazines and phthalonitriles

Next-generation aerospace programs demand higher temperatures for structural and hot-section components, fostering advances in thermoset resin chemistry.

Read MoreAdditives and modifiers: Matrix optimization

New and reengineered modifiers for thermosets and thermoplastics target previously elusive goals in composites processing and performance.

Read More

.jpg;maxWidth=300;quality=90)