Software Update: Simulating a repair

CompositesWorld recently hosted a webinar with Altair’s (Troy, Mich.) Robert Yancey and Tim Harrell, structural analyst, United Launch Alliance (Centennial, Colo.), who discussed the use of Altair’s OptiStruct software to design a doubler repair patch for a rocket motor that was damaged with a gouge defect. “These composite components are very costly, so therefore if a manufacturing default happens, it is advantageous to fix the part,” explains Harrell.

CompositesWorld recently hosted a webinar with Altair’s (Troy, Mich.) Robert Yancey and Tim Harrell, structural analyst, United Launch Alliance (Centennial, Colo.), who discussed the use of Altair’s OptiStruct software to design a doubler repair patch for a rocket motor that was damaged with a gouge defect.

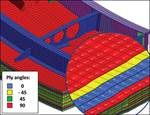

“These composite components are very costly, so therefore if a manufacturing default happens, it is advantageous to fix the part,” explains Harrell. Doublers are commonly used in launch vehicles, he explains, to repair sandwich facesheet defects, such as gouges or depressions, because they locally increase the strength of the facesheet in the area of the repair. “People have developed simple equations to tell how many plies to place, and rules of thumb as to what the size and shape the patches should be,” says Harrell. “But, there hasn’t been a method for showing the minimum size and shape of a repair.”

A secondary consideration is how loads may be redistributed in the vicinity of the repair due to changes in stiffness associated with the repair. Because a doubler’s strength and stiffness are comparable to that of the facesheets, its influence on the overall extensional and bending stiffness of the sandwich can be significant. “When using a doubler, we sometimes see secondary stress peaking from the nominal fibers to the repair fibers,” says Harrell. More plies draws more load and, therefore, more stress.

Free-size optimization within OptiStruct was used to determine the shape required to minimize the stress, as well as the number of plies needed. While no manufacturing constraints were applied, a maximum thickness equal to four plies was used to bound the problem. “In the end, not only did we get a size- and shape-optimized doubler repair, we eliminated the stress peaking,” says Harrell. “These same optimization constraints can be used to analyze defects on other finite element models with similar defects to determine an optimized patch for different geometry and loading conditions. Harrell pointed to further work to be done to analyze ply-by-ply properties to determine if the patch changes. “If we can use this solution in critical areas, where the margins of safety are very small, we may not have to worry about stress peaking and, therefore, our repair would be equivalent to the intent of the nominal design.”

Editors note: This short article is a sidebar to a ffeature article titled "Software update: Simulation saves." Read the main article by clickign on its title under "Editor's Pick's at top right.

Related Content

-

The basics of composite drawing interpretation

Knowing the fundamentals for reading drawings — including master ply tables, ply definition diagrams and more — lays a foundation for proper composite design evaluation.

-

Jeep all-composite roof receivers achieve steel performance at low mass

Ultrashort carbon fiber/PPA replaces steel on rooftop brackets to hold Jeep soft tops, hardtops.

-

Multi-material steel/composite leaf spring targets lightweight, high-volume applications

Rassini International was challenged by Ford Motor Co. to take weight out of the F-150 pickup truck. Rassini responded with a multi-material steel/composite hybrid leaf spring system that can be manufactured at high volumes.