SAMPE Long Beach 2013 review

The Society for the Advancement of Material and Process Engineering’s (SAMPE, Covina, Calif.) spring conference and exhibition is the organization’s largest event every year, and the 2013 edition, held May 6-9 in Long Beach, Calif., was no exception.

The Society for the Advancement of Material and Process Engineering’s (SAMPE, Covina, Calif.) spring conference and exhibition is the organization’s largest event every year, and the 2013 edition, held May 6-9 in Long Beach, Calif., was no exception. The number of exhibitors, 400, was a SAMPE record. Notably, SAMPE reported that 70 exhibitors were on the show floor for the first time, a testament to the overall vitality on the supply side of the advanced materials market. SAMPE’s official count of attendees was 4,910. Although it’s possible that the effects of the U.S. government’s budget sequestration had a slightly depressive effect on attendance, the consensus on the show floor was that SAMPE 2013, overall, had been positive. (See a sampling of new products that were on display in Long Beach in the “SAMPE 2013 New Product Showcase,” under "Editor's Picks," at top right).

SAMPE 2013 marked the last time this show will be either a spring event or held on its own. SAMPE is moving its biggest event to the fall in 2014 to create a joint show with the American Composites Manufacturers Assn.’s (ACMA, Arlington, Va.) COMPOSITES conference and expo. The still-unnamed joint event will be held Oct. 14-16 in Orlando, Fla., and is intended to attract attendees from the full spectrum of composites industry professionals and represent the entire breadth of markets served, from marine and energy manufacturers to automotive and aerospace engineers. The move also means that SAMPE Tech, traditionally held in the fall, will move to spring 2014.

That, however, is the future. SAMPE 2013 very much reflected the present, with much attention paid to new and emerging technologies in aerospace and other high-performance applications. But the automotive industry and the potential use of carbon fiber in structural automotive parts grabbed its fair share of attention on the show floor and in conference presentations.

SAMPE 2013 officially started with keynote speaker Dr. John Tracy, CTO and senior VP, engineering, operations and technology, at The Boeing Co. (Chicago, Ill.). There was a standing-room-only crowd on hand for his discussion of the future of structures and materials in the aerospace industry.

Tracy, a former math teacher, recounted his early days at Boeing and his ascension through the ranks before bringing the audience up to date on Boeing’s situation. This includes a $392 billion backlog, which represents more than 4,400 commercial airplanes. He noted that the 787-10 variant of the Dreamliner is progressing quickly to first flight and, in regard to the 787-9, acknowledged (amid chuckles from the audience), “I know more about lithium-ion batteries than I could ever have imagined. I just wish I could have learned it under different circumstances.”

Tracy noted that commercial air travel since 1980 has been remarkably resilient, averaging 5 percent growth per year through four recessions, two financial crashes, two Gulf Wars, one oil shock, one near pandemic (SARS) and 9/11. If growth in the gross domestic product in the U.S. is equal to or greater than 3 percent, Tracy said, aircraft travel increases at least 5 percent.

By 2031, Tracy said, expect to see almost 40,000 commercial airplanes in service (double the number in the air today), with 69 percent of those single-aisle, 23 percent twin-aisle, 5 percent regional and 3 percent in the jumbo category.

A big fan of composites early on, Tracy noted that the 787 represents a paradigm shift in aircraft design and materials use. He said, for instance, that the 747 requires more than 2 million holes to be drilled and filled; the 787, in contrast, requires 10,000 holes to be drilled and filled. Fewer fasteners are credited to the use of much more integrated structures.

On the other hand, the high development cost of new materials requires that they “earn their way by providing value to the customer,” Tracy pointed out. “You can’t get away with the ‘wow’ factor only. We always need breakthrough performance to add a new material to an aircraft.”

The next breakthrough material, he observed, might be ceramic-matrix composites (CMCs), which are the focus of Boeing’s Continuous Lower Energy, Emissions and Noise (CLEEN) Technologies Development program. CLEEN includes the development and testing of a CMC jet engine nozzle.

Looking ahead, Tracy urged composites engineers and professionals to focus on aircraft architecture with fewer fasteners and more cobonding. “We have to come up with new airplane architectures that have more integrated structures,” he said. Tracy also noted that Boeing and the entire aerospace industry needs to boost its computational power. Physically testing components, he underscored, is expensive, difficult and time-consuming. In his “atoms to airplanes” vision, physical labs would be combined with virtual labs to prove designs before fiber and resin are combined.

On Wednesday, Dr. Klaus Drechsler, director of the SGL Institute for Carbon Composites at the Technical University of Munich (Germany), delivered a companion keynote address on “Research and Education Networks – An Approach for Sustainability in Composite Developments.” His presentation discussed changes that can be adopted to make R&D, process chains, and the advanced materials workforce more efficient.

Breaking bridges

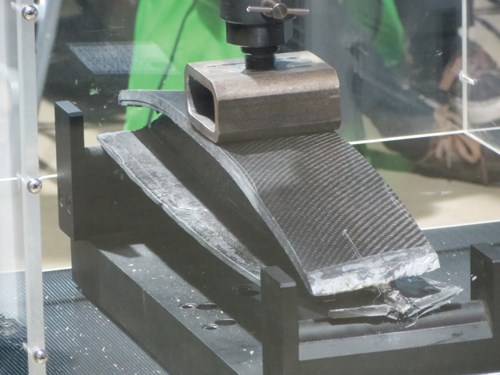

One of the staples of the SAMPE show is the student bridge-building competition. Teams representing a variety of colleges and universities enter bridges made of carbon fiber, aramid fiber, glass fiber or natural fiber using I-beam and square-beam designs. On the second day of the show the bridges are stressed to the breaking point and measured according to the force at breakage. This value is compared to the mass of the bridge to determine winners. First-, second- and third-place awardees were as follows:

- Aramid/carbon, I-beam: Texas State University, University of British Columbia (Canada), University of Washington

- Glass fiber, I-beam: University of Washington, University of Delaware, Cal Poly San Luis Obispo

- Natural fiber, I-beam: University of Delaware, McGill University, Harbin Engineering University (China)

- Aramid/carbon, square-beam: University of Washington, Western Washington University

- Glass fiber, square-beam: Harbin Engineering University, University of Washington, University of Delaware

- Natural fiber, square-beam: University of Delaware, University of Washington, Harbin Engineering University

- Open design: University of Washington, Western Washington University, Brigham Young University

Exhibitor accolades

The conference came to a close with a luncheon presentation by Mickey Abaris Training Resources Inc. (Reno, Nev.) and Plascore Inc. (Zeeland, Mich.) received recognition for 25 years as SAMPE exhibitors, and Nippon Graphite Fiber Corp. (Montreal, Quebec, Canada, and Tokyo, Japan) and Composites Horizons LLC (Covina, Calif.) were recognized for 20 years of continuous support as exhibitors.

For further information about the combined SAMPE/ACMA event or the new spring SAMPE Tech conference, contact SAMPE’s Michelle Tubb, Tel.: (626) 331-0616 x603; E-mail: michelle@sampe.org; Web site: www.sampe.org.

Related Content

Materials & Processes: Fabrication methods

There are numerous methods for fabricating composite components. Selection of a method for a particular part, therefore, will depend on the materials, the part design and end-use or application. Here's a guide to selection.

Read MoreThe importance of resin mixing procedures in the composites shop

What is considered to be common knowledge when storing, handling, weighing, mixing and deploying epoxy resins and adhesives has brought to light the need for tighter control, improved practices.

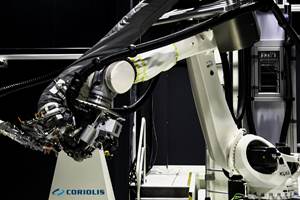

Read MoreCoriolis Composites installs AFP machine at Sabanci University

C1 robot contributes to technology development at the Integrated Manufacturing Technologies Research and Application Center (SU IMC) in Istanbul.

Read MoreWomen in the Composites Industry brings together women for networking, educational opportunities

Aiming to support the growth of women in this industry, the WCI industry group and its partners recently held its first live training event hosted by Owens Corning.

Read MoreRead Next

SAMPE 2013 Long Beach new product showcase

The SAMPE 2013 trade show (May 6-9, in Long Beach, Calif.) was the venue for introductions of a large number of new composite materials, technologies and manufacturing processes. Here's the HPC editorial staff's compilation of what was on display.

Read MoreCW’s 2024 Top Shops survey offers new approach to benchmarking

Respondents that complete the survey by April 30, 2024, have the chance to be recognized as an honoree.

Read MoreFrom the CW Archives: The tale of the thermoplastic cryotank

In 2006, guest columnist Bob Hartunian related the story of his efforts two decades prior, while at McDonnell Douglas, to develop a thermoplastic composite crytank for hydrogen storage. He learned a lot of lessons.

Read More

.jpg;maxWidth=300;quality=90)