SAMPE 2010 Seattle Preview

New decade, new venue, new economy, new M&P opportunities.

The Society for the Advancement of Material and Process Engineering’s (SAMPE) Spring Conference and Exhibition returns this year to the West Coast after its second East Coast appearance in Baltimore. But it’s not returning to its traditional home base in Long Beach. Instead, SAMPE 2010 will be held for the first time in Seattle, Wash., a key base of operations for aerospace manufacturing giant The Boeing Co. and near many U.S. and Canadian M&P suppliers in the Pacific Northwest. SAMPE organizers say they expect as many as 300 exhibitors and 5,000 total attendees to converge at the Washington State Convention Center for the four-day event, May 17-20.

Show visitors will find a full agenda of educational offerings: Two keynoters and seven featured lecturers will headline a program that also includes eight tutorials (half-day basic training courses), 58 conference sessions with multiple paper presentations in each (see “SAMPE 2010 Seattle at a Glance,” under "Editor's Picks"), and six panel discussions.

New directions for a new decade

In the wake of the Boeing 787’s first flight and expected production ramp-up this year and the improving economic picture in world markets and the advanced composites sector, SAMPE’s 2010 show theme reflects the growing tide of cautious optimism: “New Materials and Processes for a New Economy.” The SAMPE conference schedule will not lack for presentations that underscore awaiting opportunities, particularly in the aerospace and wind energy sectors.

Dr. John Russell, a senior materials engineer with the U.S. Air Force Research Laboratory (AFRL, Wright-Patterson AFB, Ohio) will speak Tuesday on “Design and Manufacture of Composites on Military Aircraft: Where Are We At and Where Do We Need to Go?” Russell will contend that, despite the fact that composites have reached 50 percent by weight in the Boeing 787, there is much to do to give military aircraft designers the confidence to increase composites content in planes beyond the current 25 percent. He plans to outline what needs to be done.

On Wednesday, Dr. Andrew Johnston of the National Research Council Canada (Ottawa, Ontario) will discuss the dynamic and innovative polymer matrix composites sector north of the U.S./Canada border in “Composites in Canada.”

On Thursday morning, Dr. Enrique Garcia of turbine builder Gamesa SA (Vitoria, Álava, Spain) will discuss Gamesa’s efforts with machine builder MTorres (Torres de Elorz, Navarra, Spain) to reduce labor by automating blade manufacture, using a new blade design adapted to what is said to be the world’s first automated dry tape layup machine. Garcia’s presentation will be followed by one from Dr. Ian Chatting, VP of global research at Vestas Wind Systems A/S (Randers, Denmark), who will trace the rapid evolution of wind turbines from small-scale, low-kilowatt generators to today’s massive multi-megawatt systems that have improved energy harvesting efficiency a hundredfold in just 25 years. Chatting will outline the challenges faced by blade manufacturers in terms of reliability and lifetime cost of energy and illustrate how software-based analysis, test and validation tools have enabled lighter and more robust composite blades that reduce loads on the rest of the turbine structure.

Nano-enhancement of composites

Following a keynote speech on applications of carbon nanotubes (CNTs) in polymer nanocomposites, given by nanotech pioneer Moribundo Endo (Shinshu University), one of the more intriguing panels will address “Commercializations of Nanotechnology,” which has risen rapidly from a “what if?” research upstart to a worldwide investment juggernaut (valued in excess of $15 billion USD in 2008 alone). The panel moderators, Prof. Joseph H. Koo of the University of Texas and Dr. Louis A. Pilato of Pilato Consulting (Bound Brook, N.J.), will colead a discussion of the ways that nanotechnology R&D already has generated new materials and processes that benefit the composites industry. Panelists scheduled to share commercialization success stories will be Dr. James R. Von Ehr II, Zyvex Technologies Inc. (Columbus, Ohio); Max Lake, Applied Sciences Inc. (Cedarville, Ohio); Dr. Joseph Lichtenhan, Hybrid Plastics Inc. (Hattiesburg, Miss.); Dr. James Seferis, GloCal Network Corp. (Seattle, Wash.); Dr. Beny Wang, Florida State University, Tallahassee, Fla.); Peter Antoinette, Nanocomp Technologies (Concord, N.H.); and Dr. Horst Adams, Bayer MaterialScience, (Pittsburgh, Pa.).

For more information about the SAMPE 2010 Conference & Exhibition, contact Priscilla Heredia, Tel.: +1 (626) 331-0616 x610; E-mail: priscilla@sampe.org. Web site: http://SAMPE2010.sampe.org.

Related Content

Infinite Composites: Type V tanks for space, hydrogen, automotive and more

After a decade of proving its linerless, weight-saving composite tanks with NASA and more than 30 aerospace companies, this CryoSphere pioneer is scaling for growth in commercial space and sustainable transportation on Earth.

Read MoreNovel dry tape for liquid molded composites

MTorres seeks to enable next-gen aircraft and open new markets for composites with low-cost, high-permeability tapes and versatile, high-speed production lines.

Read MoreMaterials & Processes: Fibers for composites

The structural properties of composite materials are derived primarily from the fiber reinforcement. Fiber types, their manufacture, their uses and the end-market applications in which they find most use are described.

Read MoreDrag-based wind turbine design for higher energy capture

Claiming significantly higher power generation capacity than traditional blades, Xenecore aims to scale up its current monocoque, fan-shaped wind blades, made via compression molded carbon fiber/epoxy with I-beam ribs and microsphere structural foam.

Read MoreRead Next

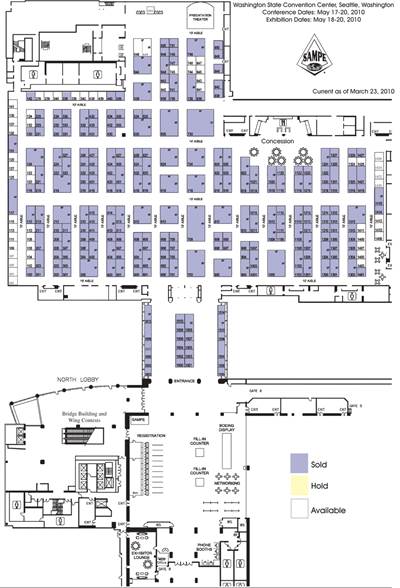

SAMPE 2010 Seattle Exhibitor List

A list of exhibitors, booth assignments and a show floor map for the SAMPE 2010 Seattle trade show, May 17-20, 2010.

Read MoreFrom the CW Archives: The tale of the thermoplastic cryotank

In 2006, guest columnist Bob Hartunian related the story of his efforts two decades prior, while at McDonnell Douglas, to develop a thermoplastic composite crytank for hydrogen storage. He learned a lot of lessons.

Read More

.jpg;maxWidth=300;quality=90)