Recycled carbon fiber proves its potential for aircraft interiors

An Airbus-led team characterizes RCF veils and shows their ability to best glass fiber composite sidewalls in cost, weight and surface finish.

The Composite Technology Center (CTC, Stade, Germany), a subsidiary of aircraft manufacturer Airbus (Toulouse, France), is dedicated to developing new technologies for the production and assembly of carbon fiber-reinforced plastic (CFRP) composites for aircraft. In December 2014, CW reported on a CTC project designed to demonstrate the use of recycled carbon fiber (RCF) materials in a full-scale aircraft interior sidewall panel (see “Recycling carbon fiber for structural applications” under “Editor's Picks,” at top right). Demonstration panels are now complete and in testing. When CW revisited the project, CTC researcher Tassilo Witte explained more about its motivation and future implications. “Currently, production of recycled carbon fiber exceeds the market demand because too few potential applications using these materials have been investigated up to now,” he noted. “With a recycling capacity of more than 1,000 MT per year in Germany alone, there is a significant source of raw material to be tapped!” And more recyclate is generated each day.

The CTC’s project’s goal, then, was to begin developing parts using this RCF stockpile. “Instead of using continuous glass fiber,” says Witte, “we use short-length recycled carbon fiber, which competes directly, performance-wise.”

Targeted development

Witte walks CW through project’s timeline. “At the beginning of 2013, we started looking at CFRP recycling and talking to recycling companies, analyzing the supply chain from raw material production all the way to companies who use the recycled CF products.” Witte then assembled a team that included CarboNXT (Stade, Germany), RCF materials supplier; Gurit (Kassel, Germany), a phenolic prepregger; cabin lining manufacturer Diehl Aircabin (Laupheim, Germany) and aircraft OEM Airbus.

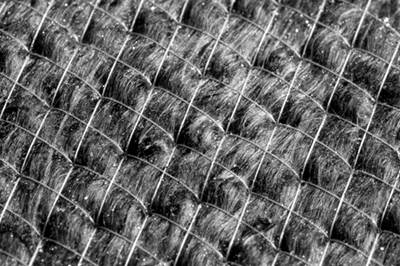

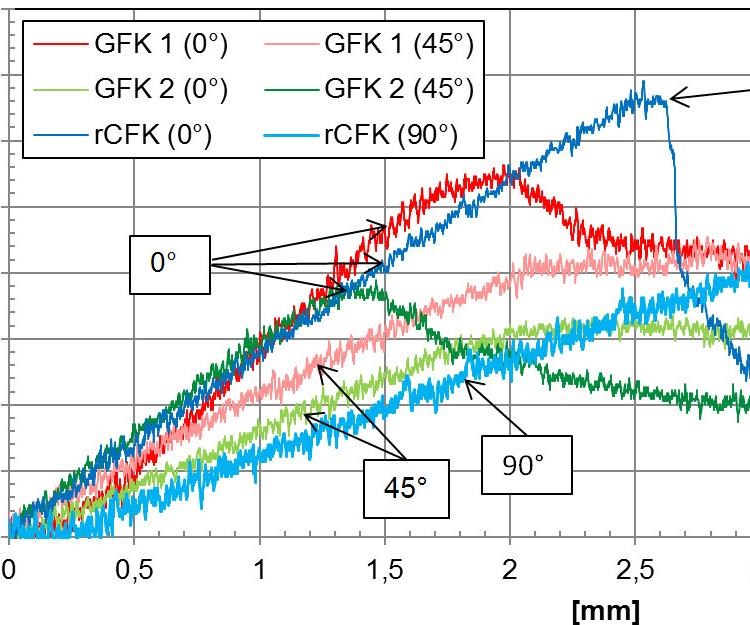

“Our first goal was to investigate the performance of RCF materials,” Witte recalls, noting one of the first questions the team faced: “Was it even possible to reuse the reclaimed fibers in an aircraft application?” CTC characterized veils made from CarboNXT RCF materials as well as monolithic laminates made with the veils. Produced by CFK Valley Recycling (Wischhafen, Germany), these RCF veils began as either dry fiber scraps, prepreg waste or parts. The materials were sorted according to state of processing and type of carbon fiber, and then crushed in preparation for pyrolysis. Temperatures of 400-500°C in the oxygen-excluded pyrolysis furnace removed any remaining matrix materials but preserved fiber properties. CFK Valley Recycling then conditioned the fiber surface for optimum adhesion as required by its prospective end-use. The fibers then were cut to a standard length and processed into a nonwoven veil, using either wet-lay or air-lay textile machines (see “Recycled carbon fiber update: Closing the CFRP lifecycle loop” under “Editor's Picks”). After six months of testing, CTC had evaluated the RCF material properties and determined that they could meet basic composite laminate requirements.

“Our next goal,” says Witte, “was to identify a part for demonstration.” Interior panels were a good candidate, because they serve as aesthetic surfaces but are not primary structures —a use for which RCF materials have already demonstrated a good fit, for example, in automotive seat components (see “CAMISMA’s car seat back: Hybrid composite for high volume" under “Editor's Picks”). By August 2014, a typical airliner interior cabin sidewall was chosen. Considered secondary structure, these curved liners are attached to the fuselage by clips and provide an interior surface with cutouts for windows but carry no fuselage loads, as do window frames.

Only the woven S-glass fabric of the liners was targeted for replacement. “We decided to leave everything else unchanged,” says Witte, “because it offered the most practical approach to demonstrate usability, near term.” The team outlined the process requirements and began work to optimize the RCF material for process and equivalent performance at the same or less weight.

By the end of 2014, CTC and its supply chain team had produced the first batch of short-fiber RCF veil materials prepregged with phenolic resin and measured their properties. Several months later, the first sandwich specimens were made using RCF veils and honeycomb core.

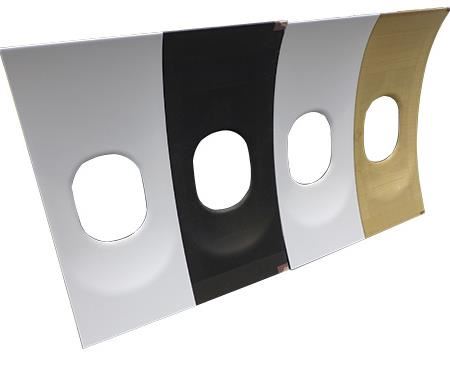

“Now we began to look at the final part design and proceeded through several rounds of optimizing the RCF veil for fiber length, areal weight and thickness,” says Witte. By July 2015, the product design and semi-finished product (prepreg) specification were completed. The following month, the first production run of RCF veil prepreg, with phenolic resin, was completed at Gurit. By September, the project team had made four full-size (1.2m tall by 1m wide) demonstrator parts at the Diehl Aircabin facility.

Success on the first try

Full-scale demonstration sidewalls were molded via the conventional “crushed core” process (see “Advanced materials for aircraft interiors” under “Editor's Picks”) that is typically used by Boeing, Airbus and their Tier 1 suppliers to produce curved interior panels. Honeycomb core, typically made from Nomex aramid paper, is crushed down to a predetermined thickness in a large press by heated steel molds under pressures greater than 10 bar. Processing times are approximately 15 minutes, after which a decorative, wear-resistant film is typically applied (see the photo at left).

The process reportedly went more smoothly than anyone expected. “After 18 months of development, we wouldn’t have thought that the first part produced in the serial machines would be perfect, ready to use,” recalls Witte. “But we produced four parts, one after each other, in two hours with no issues, and I was amazed at how good the surface quality was.”

Although there often is a dimpling effect where the laminate bridges the honeycomb cells in conventional sidewall production, “with the RCF material we didn’t see that effect,” Witte notes. Beyond its potential to reduce molding time and cost in post-finishing, the RCF sidewalls also achieved a 22% weight reduction.

The sidewalls are currently undergoing mechanical properties testing and tests against conventional sidewalls in categories that include noise abatement (acoustic damping) and thermal performance. Acceptable fire, smoke and toxicity (FST) performance was confirmed during coupon and laminate plate testing before full-scale parts were molded. “The plan is that by mid-2016, we will reach TRL 6 and start preparing for serial production,” says Witte.

“The entire composite industry must start to change from a linear supply chain to a circular supply chain,” says Witte, “and we are now one step closer to a circular lifecycle loop for CFRP materials!”

Related Content

Novel dry tape for liquid molded composites

MTorres seeks to enable next-gen aircraft and open new markets for composites with low-cost, high-permeability tapes and versatile, high-speed production lines.

Read MoreMaterials & Processes: Fibers for composites

The structural properties of composite materials are derived primarily from the fiber reinforcement. Fiber types, their manufacture, their uses and the end-market applications in which they find most use are described.

Read MoreMaterials & Processes: Composites fibers and resins

Compared to legacy materials like steel, aluminum, iron and titanium, composites are still coming of age, and only just now are being better understood by design and manufacturing engineers. However, composites’ physical properties — combined with unbeatable light weight — make them undeniably attractive.

Read MoreComposite rebar for future infrastructure

GFRP eliminates risk of corrosion and increases durability fourfold for reinforced concrete that meets future demands as traffic, urbanization and extreme weather increase.

Read MoreRead Next

Recycled carbon fiber update: Closing the CFRP lifecycle loop

Commercial production of recycled carbon fiber currently outpaces applications for it, but materials characterization and new technology demonstrations promise to close the gap.

Read MoreRecycling carbon fiber for structural applications

Research aims to characterize recycled carbon fiber (RCF) for use in aero interiors and also to recycle continuous carbon fiber.

Read More

.jpg;maxWidth=300;quality=90)