NASA looking for new core half the areal weight of honeycomb and foam

Two $550K grants to be awarded for new lightweight cores research. Applications due by Dec. 16, 2014.

SpiderFab is one example of the new technology being driven by NASA’s Game Changing Development program. SOURCE: NASA.

The “Ultra-Lightweightcore Materials For Efficient Load-Bearing Composite Sandwich Structures” grant solicitation has been issued as part of NASA’s Game Changing Development (GCD) program. The GCD seeks to identify and rapidly mature innovative novel ideas and approaches that have the potential to revolutionize future space missions as well as provide solutions to significant national needs, like energy and manufacturing. CW has reported extensively on the composite cryotank, which is a GCD program.

Other NASA Game Changing Development programs include (from left to right):

3-D printed rocket engine parts,

Robonaut 2 with new climbing legs for zero-gravity mobility,

Made In Space’s first zero-gravity 3-D printer and

Firefly Space Systems’ low-cost small satellite launch vehicle which uses a methane-fueled aerospike engine and composite cryotanks.

SOURCE: All images sourced from NASA except Firefly sourced from aviationweek.com.

GCD issued the “Ultra-lightweight Core Materials for Efficient Load-Bearing Composite Sandwich Structures” solicitation on Oct. 24, 2014. It seeks proposals for the maturation and development of scalable methods to manufacture ultra-lightweight core materials as lower mass alternatives to honeycomb or foam cores in composite sandwich structures. Specifically:

“The development of advanced manufacturing techniques has led to the production of lightweight, hierarchical structures with the potential for use as lower mass alternatives to conventional core components in composite sandwich structures. NASA is interested in scaling up manufacturing processes to produce ultra-lightweight core materials that could be used to produce large-scale composite sandwich structures. The envisioned development effort would demonstrate that materials are a cost-effective and lighter weight alternative to conventional core materials. The overall goal of the Appendix is to develop and demonstrate scalable and cost-effective manufacturing approaches to produce ultra-lightweight core materials both as flat panels and curved structures. The resultant structures will have half or less the areal density of conventional honeycomb cores, while retaining equivalent, or better, mechanical properties.”

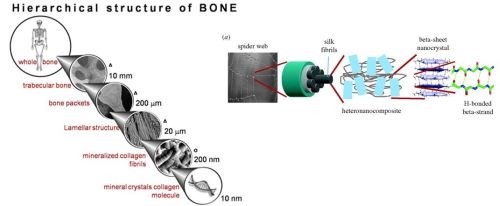

Materials with hierarchical structures include bone and spider silk, which achieve very high strength and/or stiffness with very lightweight. MIT’s recent 3-D printing of core materials — "Ultralight, Ultrastiff Mechanical Metamaterials” — is another example, noting that they have developed microarchitectures into the materials which are then fed into the additive manufacturing machines to create unique macroscale architectures.

The different arrangement of material structures at the various scales within hierarchical materials like bone and spider silk work in concert to perform the diverse mechanical, biological and chemical functions, which enable unique performance advantages.

SOURCE: Surface Engineering, Mawson Institute, University of South Australia (left) and Interface Journal of the Royal Society and Markus J. Buehler.

This ultralight core initiative is part of a greater Mars mission focus:

Composite sandwich structures are used extensively within the aerospace industry and in other applications where reducing weight while maintaining structural strength is important. A common use for these sorts of composites is the shrouds for launch vehicles and other key technology components that will enable our journey to Mars.

Over the next year, NASA’s Space Technology Mission Directorate (STMD) will continue to seek industry and university partnerships to assure the agency has the capabilities it needs, while helping America maintain its leadership in the technology-driven global economy. These investments will focus on in-space propulsion and advanced high-power solar arrays; robotics and avionics for outer planetary exploration, especially high-reliability and low-mass, deep ice penetration systems; advanced materials, including large composite structures; and space observatory systems, with a focus on advanced optical coating materials.

This page says NASA expects to make two awards of up to $550,000 each for this first development phase. The Game Changing Development program for STMD is managed by NASA's Langley Research Center in Hampton, Virginia. For the full original posting, click here.

Related Content

Thermoplastic composites welding advances for more sustainable airframes

Multiple demonstrators help various welding technologies approach TRL 6 in the quest for lighter weight, lower cost.

Read MoreCryo-compressed hydrogen, the best solution for storage and refueling stations?

Cryomotive’s CRYOGAS solution claims the highest storage density, lowest refueling cost and widest operating range without H2 losses while using one-fifth the carbon fiber required in compressed gas tanks.

Read MorePlant tour: Joby Aviation, Marina, Calif., U.S.

As the advanced air mobility market begins to take shape, market leader Joby Aviation works to industrialize composites manufacturing for its first-generation, composites-intensive, all-electric air taxi.

Read MoreMaterials & Processes: Fabrication methods

There are numerous methods for fabricating composite components. Selection of a method for a particular part, therefore, will depend on the materials, the part design and end-use or application. Here's a guide to selection.

Read MoreRead Next

CW’s 2024 Top Shops survey offers new approach to benchmarking

Respondents that complete the survey by April 30, 2024, have the chance to be recognized as an honoree.

Read MoreComposites end markets: Energy (2024)

Composites are used widely in oil/gas, wind and other renewable energy applications. Despite market challenges, growth potential and innovation for composites continue.

Read MoreFrom the CW Archives: The tale of the thermoplastic cryotank

In 2006, guest columnist Bob Hartunian related the story of his efforts two decades prior, while at McDonnell Douglas, to develop a thermoplastic composite crytank for hydrogen storage. He learned a lot of lessons.

Read More

.jpg;maxWidth=300;quality=90)