Metal-matrix composites used to lighten military brake drums

Century Inc.'s combination metal-matrix composite (MMC)/aluminum brake drum is a lightweight alternative to cast iron and steel brake drums in military vehicles.

In military vehicles, weight reduction in structural components translates to greater operational flexibility — the ability to carry more payload, drive more easily over unimproved roads and/or support more protective armor. Working with the U.S. Army’s Tank Automotive Research Development and Engineering Center (TARDEC, Warren, Mich.), Century Inc. (Traverse City, Mich.) has developed a combination metal-matrix composite (MMC)/aluminum brake drum as part of an initiative to transition away, wherever possible, from heavy cast iron and steel to lighter weight materials in military vehicle components.

While MMCs have been used for brake rotors and pads for years, they are typically costly and often require batch processing. In the past, says Century’s new-business development manager Jim McManus, brake manufacturers have tried to form an all-composite component by die casting an MMC that consists of molten aluminum reinforced with silicon carbide (SiC) filler. Unfortunately, the resulting parts, while lightweight, have had low ductility (only about 0.5 percent), which resulted, he says, in low fatigue strength and inadequate toughness for the friction wear surface. In addition, the material was typically difficult to drill and machine, a factor that made the product too costly to bring to market.

Since then, the company has developed its trademarked Light-weighting Technology, which successfully combines an MMC brake wear surface inside a low-cost and easy-to-machine cast-aluminum drum brake body. The result is a 15-inch/381-mm ID drum with a 4-inch/101-mm wide frictional wear surface. Accordingly, the brake drum is referred to as a “15X4.”

The 15X4’s hybrid design was made possible with the aid of several software programs. Century used Pro/ENGINEER Wildfire 3.0 from PTC - Parametric Technology Corp. (PTC, Needham, Mass.) iteratively with Ansys finite element analysis (FEA) software from ANSYS Inc. (Canonsburg, Pa.) to ensure the design could meet the Army’s substantial performance specifications. The brake drum has to withstand the vehicle’s torque load when the brake shoe meets the frictional wear surface, with adequate drum strength (wall thickness) and robust bolt attachments to the vehicle hub. According to McManus, the drum must have adequate strength and stiffness in the hoop direction and adequate fatigue strength to endure cyclic loading over its life. Moreover, it must dissipate the tremendous frictional heat that is generated, which can be as high as 500°F/260°C. Adding complexity to the design was the requirement that it be easily castable from molten aluminum. Century used MagmaSoft mold-filling simulation software from MAGMA Giessereitechnologie GmbH (Aachen, Germany) to ensure that the mold could be readily filled with molten aluminum within the processing time window while minimizing part porosity.

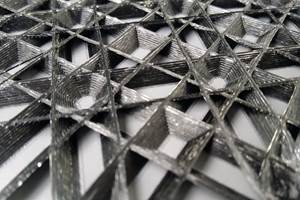

But the key to Century’s Light-weighting Technology is the company’s ability to rapidly create the MMC material. Century 3+ LLC, a division within Century, has an exclusive license from a German machine company for its trademarked Ring Extruder, a multiple-screw extruder that forms ceramic preforms in a continuous production process. SiC filler is combined with a proprietary mixture of fibers and inorganic and organic binders and then extruded to form cylindrical preforms that, after proprietary thermal processing and machining, can be infused with either molten metal or a silica-based binder to produce an MMC or a ceramic-matrix composite (CMC) part, respectively. Other, noncircular preform shapes, with different additives, are possible as well, says McManus.

The drum brakes are made via a process called squeeze casting. After the ceramic preform is placed in a two-part steel mold, molten aluminum is injected slowly to prevent the preform from moving or cracking and to avoid any turbulence, which can trap air, producing voids. Then the mold halves are clamped under high pressure (as much as 10,000 psi), forcing the molten metal to infiltrate the preform and flow throughout the mold cavities. The extremely high pressure also improves the fatigue strength of the metal in the finished part. Under pressure, the infused preform becomes an integral part of the brake drum, selectively reinforcing only the part’s inner frictional wear surface.

According to McManus, the MMC/aluminum brake drum weighs 45 percent less than a cast-iron counterpart and dissipates heat faster. “And, this weight savings is unsprung weight,” he contends, pointing out that “each pound of unsprung weight saved equates to three to fives times as much sprung mass savings elsewhere in the vehicle.”

The Army and representatives of military vehicle programs reportedly have expressed interest in developing prototypes for future military vehicle testing, and other brake configurations and sizes might be prototyped as well.

Related Content

Natural fiber composites: Growing to fit sustainability needs

Led by global and industry-wide sustainability goals, commercial interest in flax and hemp fiber-reinforced composites grows into higher-performance, higher-volume applications.

Read MoreMaterials & Processes: Fibers for composites

The structural properties of composite materials are derived primarily from the fiber reinforcement. Fiber types, their manufacture, their uses and the end-market applications in which they find most use are described.

Read MoreDrawing design cues from nature: Designing for biomimetic composites, Part 2

As biomimetic design continues to inform composites manufacturing, technologies like 3D printing, tailored fiber placement, braiding and filament winding prove strong candidates for making these structures a reality.

Read MoreRUAG rebrands as Beyond Gravity, boosts CFRP satellite dispenser capacity

NEW smart factory in Linköping will double production and use sensors, data analytics for real-time quality control — CW talks with Holger Wentscher, Beyond Gravity’s head of launcher programs.

Read MoreRead Next

Composites end markets: Energy (2024)

Composites are used widely in oil/gas, wind and other renewable energy applications. Despite market challenges, growth potential and innovation for composites continue.

Read MoreCW’s 2024 Top Shops survey offers new approach to benchmarking

Respondents that complete the survey by April 30, 2024, have the chance to be recognized as an honoree.

Read MoreFrom the CW Archives: The tale of the thermoplastic cryotank

In 2006, guest columnist Bob Hartunian related the story of his efforts two decades prior, while at McDonnell Douglas, to develop a thermoplastic composite crytank for hydrogen storage. He learned a lot of lessons.

Read More