JEC Europe 2013 new product showcase

The JEC Europe 2013 trade show (March 12-14, at the Paris Expo, Porte de Versailles, Paris, France) was the venue for introductions of a large number of new composite materials, technologies and manufacturing processes. Here's the CT editorial staff's compilation of what was on display.

The JEC Europe 2013 trade show, held March 12-14 at the Paris Expo (Porte de Versailles, Paris, France), was the venue for introductions of a large number of new composite materials, technologies and manufacturing processes. Here's the CT editorial staff's compilation of what was on display on the show floor.

Infusion molding supplies

Airtech International (Huntington Beach, Calif.) brought several new products: Securlon V-45 is an economical vacuum bagging film suitable for phenolic resins; it is used for commercial autoclave processing, and has a maximum use temperature of 171°C/340°F. Thermalimide E is a high-performance bagging film for cure temperatures up to 426°C/799°F. Thermalimide E RBCS, a film that is treated on both sides with a release coating, can be used for cure cycles up to 405°C/761°F. Flashbreaker PS1 is a high-temperature/high-tensile strength polyester film that is coated with a high-tack, pressure-sensitive silicone adhesive for oven cures up to 204°C/399°F. Wrightlease 2 is a new extruded fluoropolymer pressure-sensitive tape with a silicone adhesive. Toolwright 5 is a thicker version of the same extruded fluoropolymer film, and it is also coated with silicone pressure-sensitive adhesive. Finally, the Airtech Vacuum Test Unit is used to test the vacuum integrity of all Airtech vacuum hoses and valves and the quick disconnect couplings that are attached to them.

Cobalt-free curing systems

AkzoNobel (Amersfoort, The Netherlands, and Chicago, Ill.) reported that it has extended its portfolio of cobalt-free curing solutions with the launch of its second-generation Nouryact accelerators. Based primarily on iron, the new “eco-premium” accelerators are said to work in a wide range of temperatures and have a low impact on the color of end-use products. They also boast easy replacement for existing cobalt-based accelerators and reprotedly, in some cases, have been shown to outperform cobalt, enabling curing behavior that is not achievable by conventional systems. All Nouryact accelerators are said to be 100 percent cobalt-free. The BlueCure umbrella brand is an initiative of AkzoNobel and DSM Composite Resins (Schaffhausen, Switzerland) that covers innovative cobalt-free curing technologies and products. The products are available to all resin and component manufacturers in the composites industry.

Cork core for sandwich panels

Amorim Cork Composites (Mozelos VFR, Portugal, and Trevor, Wis.) exhibited products made from natural cork, including ALUCORK, a sandwich panel with natural cork core and aluminum skins for floor panels in trains and other mass transit vehicles. The company says the advantages of cork sandwich panels include acoustic insulation and vibration damping, low thermal conductivity and a smaller environmental footprint than other common cored products. Also available is CORECORK, made of cork core and glass fiber-reinforced polymer (FRP) skins, for sidewall panels and ceiling solutions.

Thermoplastic for RTM, infusion processes

Arkema (Paris, France) featured on its stand Altuglas Composite, a polymethyl methacrylate (PMMA) that is said to be the first thermoplastic resin compatible with resin transfer molding (RTM) and infusion processes used to mold thermoset composite parts. Arkema says the resulting parts exhibit mechanical properties similar to those of thermoset parts, but their thermoplastic nature offers postcure thermoformability and recyclability. Altuglas Composite was developed by Arkema and tech center partner PPE (Pôle de Plasturgie de l’Est, Saint-Avold, France). Altuglas Composite formulations were optimized with help from molder MVC Soluções em Plásticos (São José dos Pinhais ,Brazil), materials specialist Chomarat (Le Cheylard, France) and glass fiber manufacturer 3B-the fibreglass co. (Battice, Belgium). The PMMA is designed to compete with unsaturated polyester (UPR), vinyl ester and epoxy resins with similar polymerization cycle times. It’s compatible with methacrylate-based structural adhesives and can be welded. MVC developed the first large demonstration part, using a room temperature RTM-light process with Altuglas Composite resin. The glass fabric reinforcement, processing equipment and polymerization cycle time were identical to those used by MVC for the industrial production of UPR composite parts. The new composite can be used for aesthetic semistructural composite parts, such as shaped truck parts, bus body panels and hoods for agricultural machinery. Additionally, Arkema and MVC have developed a thermoplastic solution that eliminates the need for a traditional gel coat. In this technology, the decorative layer is prepared by thermoforming a thermoplastic multilayer sheet, such as ABS/PMMA, in the mold prior to placement of the reinforcing fabric. The Altuglas Composite resin matrix naturally adheres to the ABS/PMMA surface layer.

Epoxy vinyl ester resin

Ashland Performance Materials (Dublin, Ohio) emphasized its Derakane 601 epoxy vinyl ester resin system for use in wind turbine blade manufacturing. Also featured was Maxguard low-emission gel coat, said to be suitable for marine, transportation, sanitary and wind energy applications. Ashland also announced at the show that it planned to open a new production facility for structural adhesives at its Kidderminster, U.K., site in spring 2013, where the company recently opened a new technical center. Both the production facility and the technical center are expected to ensure that Ashland’s structural adhesives customers in Europe, the Middle East, Africa and India will receive the highest levels of service and technical expertise.

Polyurethane and epoxy adhesives

Axson Technologies (Cergy, France) showcased four new products in its trademarked ADEKIT range of adhesives, including ADEKIT A722, a two-component methylene diphenyl diisocyanate (MDI)-free polyurethane, with high elasticity, targeted to automotive production. ADEKIT A722 can bond composites to metals and to thermoformed thermoplastics. The adhesive is designed to absorb mechanical stress yet maintain high structural performance. Also on offer were ADEKIT A236 two-part polyurethane for marine, ADEKIT H9952 rigid structural epoxy adhesive for rail applications and ADEKIT A645, a one-component mastic made from hybrid polymers, without isocyanates, for waterproof seals in many applications.

Styrene-emission reducer

BYK-Chemie GmbH (Wesel, Germany) introduced another new "green" additive — BYK-S 760 styrene-emission reducer for unsaturated polyester and vinyl ester resins. It comprises a combination of waxes with polar components (more than 85 percent renewable raw material content). The company reports that it is highly effective in reducing the monostyrene emissions typical of all types of polyesters and vinyl esters. The additive’s emissions reduction, however, is said to have no negative influence on interlaminar adhesion. More than 70 percent of its ingredients contain unsaturated groups, which are said to react with the resin during polymerization. It is recommended at levels of 0.3 to 1.0 percent.

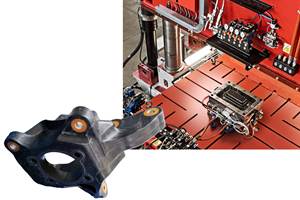

High-speed compression molding for automotive

Cannon SpA (Peschiera Borromeo, Italy) introduced its new Liquid Lay-down process, a high-speed compression molding technology marketed as an alternative to resin transfer molding (RTM) for the manufacture of automotive parts and structures. The system integrates three anthropomorphic robots in a manufacturing cell. It includes Cannon’s High Pressure Estrim metering unit and mixing head, for the dosing of two-component epoxy resin to an airless distribution die for uniform distribution, with laminar flow, of the resin/hardener mix. This is applied directly onto the carbon fiber stack outside the mold. The fabric and liquid resin are then moved to a hot press with parallelism control (for part forming), followed by a low-tonnage cold press (for controlled part cooling). Cannon says the cycle time for this process, from part to part, is five minutes. (See Fig. 1.)

Semipermanent release agent

Chem-Trend GmbH (Maisach, Germany, and Howell, Mich.) showcased its Chemlease 2185, a new-generation, semipermanent, one-part, room-temperature curing wax hybrid release agent that is effective for composites, including those with polyester matrices. The agent reportedly provides a long-wearing release film, assuming proper mold preparation and application, and the company claims that the release enables easy, multiple demoldings. It does not require an extended cure, and it allows users to save a production step because a sealer is not required. It is available as a ready-to-use liquid dispersion.

Thermoplastic prepreg

Chomarat (Le Cheylard, France) introduced TPREG, a continuous thermoplastic-impregnated reinforcement for mass production of thermoplastic composites. The company offers the material in various forms, including woven fabric, multiaxial fabric, tape or scrim, in a variety of fiber and matrix combinations and impregnation levels, depending on customer needs. The company says the molded part performance, as measured by flexural modulus and tensile strength, can equal that of a part made with thermoset resin, with the additional advantages of high impact-resistance, no styrene, high production speed, recyclability and easier storage and usability compared to traditional thermoset prepregs.

Glass and flax fiber/bio-resin prepregs

Composites Evolution Ltd.(Chesterfield, U.K.) launched glass-filled and flax-filled poly(furfuryl alcohol) (PFA) bio-resin prepregs. PFA, said to be similar to a phenolic resin, is a thermosetting system derived from hemicellulose crop waste, such as sugar cane bagasse. Aside from its positive environmental profile, it has been shown to have flame-retardant properties equivalent to that of phenolics, along with excellent chemical-resistance. As a result of more than four years of extensive R&D, the high-performance PFA bio-resin prepregs are based on aligned fabrics — natural flax, glass or carbon. They reportedly boast a combination of low weight, high mechanical properties, excellent fire-retardant properties and low environmental impact. The prepregs can be consolidated by vacuum, autoclave or compression press and are designed for a range of applications in mass transportation, furniture and construction.

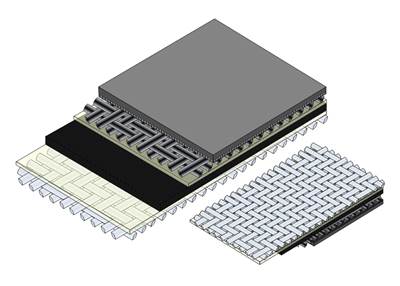

Pultrudable polyurethane

Dow Formulated Systems (Horgen, Switzerland), a business unit of The Dow Chemical Co. (Midland, Mich.), introduced its VORAFORCE TP polyurethane system for pultrusion. This solution reportedly enables efficient fabrication of composites used in industrial and domestic applications, such as in window manufacturing, building profiles, electrical infrastructure and civil engineering. Dow is targeting the polyurethane as a replacement for polyester and vinyl ester and emphasizes that it offers a styrene-free resin solution. Also on the Dow stand were carbon fiber/epoxy architectural structures infused by Affan Innovative Structures LLC (Dubai, U.A.E.) using VORAFORCE TF epoxy systems. The panels were used in the Sidra Hospital in Qatar and the Yas Mall in Abu Dhabi, U.A.E. VORAFORCE TF systems were developed specifically for infusion processes. The systems offer very low viscosity and low exothermicity, and they reportedly allow for optimal fiber wetting and efficient processing. The material enables free-form shapes and dynamic curvatures. (See Fig. 2.)

Styrene-free, 40 percent bio-based resins

At a press conference, DSM Composite Resins AG (Schaffhausen, Switzerland) unveiled its new range of Daron resins for infusion and RTM processes. Although the chemical backbone wasn’t discussed, the company claims the new resins have low inherent viscosity and are available with multiple sizing types for glass and carbon fibers. Fast cure (less than two minutes) is possible at room temperature for structural part production scenarios, including automotive parts (Daron RTM resins) and wind turbine blades (Daron 90/B18 and Daron 135/B5). A third structural infusion resin, Beyone 1, was also introduced. This styrene-free, cobalt-free formulation contains 40 percent renewable, bio-based content. Beyone resins are targeted to building, infrastructure, marine and wind industries.

Composite analysis software upgrade

Firehole Composites (Laramie, Wyo.) released Helius:CompositePro version 4.2.. The software includes the following new features and capabilities:

- New tools are available for analysis of thick-walled pressure vessels.

- Lamina and laminate data can be exported to Abaqus, ANSYS and MSC Nastran.

- Users who are interested in post-first-ply failure may specify the number of failed plies that must occur before the laminate is considered to have failed.

- When quadratic failure criteria are used, the Factor of Safety is now calculated along with the Failure Index for the seven available failure criteria.

- Users no longer have to browse for their laminate in each analysis window that is opened. If it is selected, Remember My Laminate will automatically populate each tool with the most recently used laminate.

- Tools with similar functionality (i.e., Plate Bending, Stability and Vibration) have been merged into one window with multiple tabs.

- The fabric builder tool has been improved with features that allow users to navigate forward and backward through their designs and make iterative changes.

Although Firehole Composites was recently acquired by Autodesk (San Rafael, Calif.), all Firehole product offerings will be retained and will eventually integrate Autodesk features and functions, as appropriate.

Fire retardant epoxy wet laminating system

Gurit (Newport, Isle of Wight, U.K.) introduced Ampreg 31FR, a fire retardant epoxy wet laminating system. It is formulated to meet BS476 Part 7 Class 1 FR rating and does not require a secondary fire retardant coating. With a six-hour working time, the system can be used on its own for laminating small- to medium-sized structures or in conjunction with Ampreg 21FR for larger structures. It also features a low initial mixed viscosity for fabric wetout, low exotherm and up to 200 minutes of working time at 25°C/77°F. Also new is ILATECH, a surface coating for Gurit molds, developed in conjunction with nonstick coatings supplier ILAG Industrielack AG (Lachen, Switzerland), it reportedly creates a smooth, strong and durable surface, and it also lengthens the mold’s useful life, speeds cycle times and reduces processing costs. The improved surface quality reduces the release force necessary to demold cured parts. Gurit also introduced Balsaflex UVOTEC, a next-generation balsa core material for the manufacture of sandwich panels. A new chemistry modifies Gurit’s Balsaflex surface topography and reduces resin absorption during infusion without negatively compromising faceskin adhesion. The lower resin uptake reduces the net weight of infused structures without having to alter familiar infusion processing methods. Also on display was CBS 200 press technology, which can produce finished carbon fiber composite auto body parts. With a cure duration of less than 10 minutes, the process can mint as many as 40,000 parts per year from a single tool set (see “Class A CFRP body panels: Six-minute cure” under "Editor's Picks").

High-speed RTM for automotive

Henkel (Düsseldorf, Germany) reported that it has worked with machinery manufacturer KraussMaffei (Munich, Germany) to reduce the cure time of its Loctite MAX 2 polyurethane matrix resin to just one minute in a resin transfer molding (RTM) process. The resin system and process are targeted to automotive composites manufacturing. Henkel claims that due to its low viscosity, Loctite MAX 2 penetrates and impregnates fiber material more easily and less harshly than competitors’ solutions, enabling very short injection times. The Henkel/KraussMaffei RTM process includes fabric preforming, one-minute injection and cure, postcure and finished part surface preparation. Henkel said at the show that it is seeking applications and partners to further test and assess the process.

Epoxy for high-pressure RTM

Huntsman Advanced Materials (The Woodlands, Texas) introduced the latest version of its Araldite epoxy resin matrix, formulated specifically for use in KraussMaffei’s (Munich, Germany) high-pressure resin transfer molding (HP-RTM) process. Huntsman says the resin enables five-minute production cycles and offers a 30 percent time savings, compared to first-generation HP-RTM resins. Also new: Huntsman’s fast-curing methacrylate-based adhesives, Araldite 2047-1 and Araldite 2048, which were designed, respectively, for composite bonding with limited surface preparation and the creation of flexible joints with a 90 percent elongation at break.

Automatic contacting extensometer; precision wedge grips

Instron (Buckinghamshire, England, and Norwood, Mass.) launched three new materials testing products. The AutoX750 Automatic Contacting Extensometer, which supports the execution of testing routines, including tension, bending and compression, is said to deliver more reliable data (accuracy of ±1µm) in a shorter time span. Its maximum travel distance of 750 mm/29.5 inches and multiple knife edge options make it suitable for testing highly rigid composites. The key features include automatic gauge length positioning and automatic attachment to the test specimen, with adjustable contact force. According to Instron, reducing attachment inconsistencies greatly improves test result repeatability and reproducibility. AutoX750 meets the strain measurement specifications of ASTM E83, ISO 9513, and ISO 527-1 (2011), is fully compatible with closed-loop strain control and complies with ISO 6892-1 Method A and ASTM E8.

Also on display were Instron’s 2716-028 Precision Manual Wedge Grips, which reportedly combine reliability with high precision and repeatable specimen alignment. The grips are said to be capable of meeting the stringent alignment requirements of NADCAP AC7122-1 (for nonmetal materials) and AC7101 (for metals), commonly used in aerospace. They are designed for a nominal force of 100 kN, but they can take maximum loads of 250 kN, which reportedly makes them suitable for demanding tensile tests on high-strength, fiber-reinforced polymers. The enclosed design of the grips resists dirt and debris. Symmetrical closure is achieved with a safe and easy-to-use ratchet handle; while the test proceeds, the wedge action increases the gripping force in proportion to the applied load. Pull rods allow the grips to be used inside a compatible Instron temperature chamber, which provides a temperature range from -8°C to 250°C (18°F to 482°F) without changing parts or lubricants.

TrendTracker, the new results management package for Instron’s Bluehill 3 materials testing software, stores parameters and results obtained during mechanical testing of materials and components in a central SQL database for further processing, which accelerates the data analysis workflow in a test lab.

Nesting software

JETCAM International (Monaco) launched a new version of its JETCAM Orders Controller (JOC) Premium product for nesting programming. The software is said to provide a quick way to remotely build unlimited worksheets of components for nesting, either manually or automatically. It supports multiple JETCAM Expert systems and can send CAD files for tooling to one Expert system while sending an order for nesting to another. The software’s new features include the following:

- Users can select one or more components and immediately see which nests contain these components.

- Component graphic views are available on all relevant screens.

- Cost estimation is displayed against each nest, taking into account other factors, such as material and scrap cost; machine and operator hourly rates; and setup and uploading times.

- Complex assemblies can be constructed with unlimited subassemblies.

JOC Premium II runs on Windows XP, Vista, 7 and 8 in 32- and 64-bit versions.

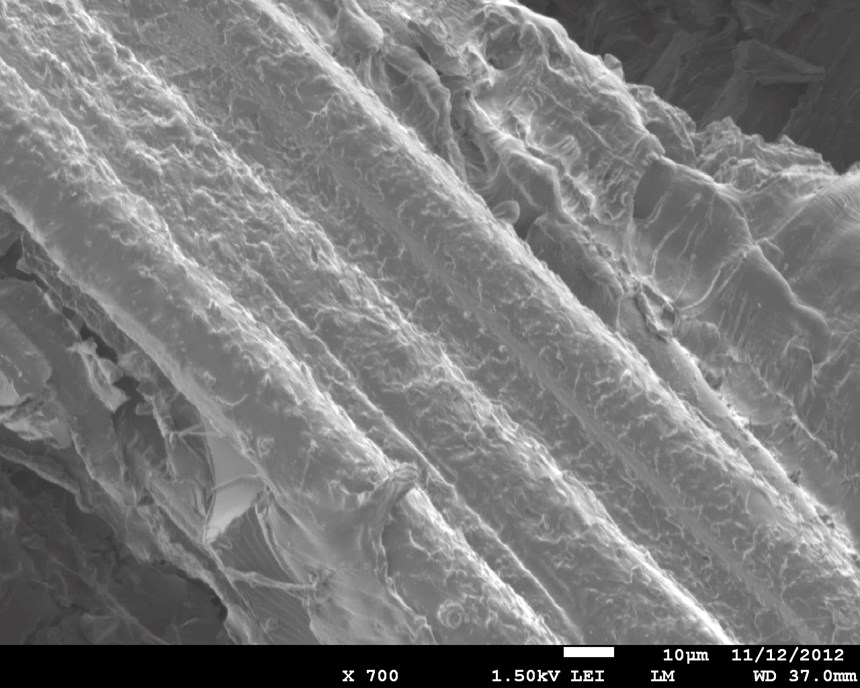

Reactive glass fiber for thermoplastic composites

Johns Manville’s (Denver, Colo.) new, engineered reactive glass fiber is expected to improve performance in structural thermoplastic composite applications. The technology development reportedly has enabled products such as StarRovRXN886, which is ready for testing in the inmold caprolactam polymerization process. According to the company, this fiber maximizes the glass/matrix bonding strength and the multiaxial impact, aging performance and dimensional stability of polyamide-6-based structural composites. It is ready for testing by customers in a variety of processes, including thermoplastic RTM, thermoplastic RIM, thermoplastic pultrusion and thermoplastic filament winding. Also new: ThermoFlow 674 and 601 chopped glass strand for reinforcement of polyamide and polybutylene terephthalate (PBT) and polyethylene terephthalate (PET) engineered thermoplastics, respectively. The products comply with Commission Regulation (EU) No 10/2011 regarding plastic materials and articles that are intended to come in contact with food. (See Fig. 3.)

External mix gun

Magnum Venus Plastech (MVP, Kent, Wash.) unveiled its new external mix gun, which is said to offer “game-changing features.” The Talon-X is engineered to provide long-lasting durability and significantly fewer wear points, translating to fewer job delays and consistent resin flow. The gun is reportedly lightweight and easy to handle; it provides a custom fit with ergonomic inserts and “applied fulcrum force,” which is said to reduce operator fatigue. The mix gun also benefits from limited part count, which makes servicing easier; advanced valve technology for dynamic discharge; rapid access design; and advanced precision pattern control. It also has an AirCat monovalve (one valve with two functions that simultaneously actuate air and the catalyst). MVP stresses that the gun has a superior thrust valve design, which includes a high-performance floating ceramic ball that provides a constantly changing wear surface, plus a carbide rod and an upper seal and rod that are exposed to less pressure. The upper seal and entire cartridge are reportedly easy to remove.

Styrene-free unsaturated polyesters

Marte SpA (Brugherio, Italy) introduced ECO ARES resins, its new range of “eco-friendly,” styrene-free unsaturated polyesters. They feature an acrylic-modified polyester, reportedly with good processability, standard curing characteristics and good mechanical properties, including hardness. In addition, says the company, the resins can be readily pigmented, and processors can maintain the same production technology they already have in place.

Hot-melt binders

Momentive Specialty Chemicals Inc. (Columbus, Ohio) displayed new products for the automotive composites market, including EPIKOTE Binder System 620, a one-component, crosslinkable powder binder that can be applied to carbon or glass fibers and fabrics in a hot-melt coating process. At a softening temperature that ranges from 80°C to 90°C (175°F to 194°F), the binder exhibits excellent workability and drapability, allowing easy preforming. During cure, the binder crosslinks to ensure good stiffness for subsequent molding in automotive mass production lines. Also on display were previously announced products for fast mass production: EPIKURE 05500 fast-cure epoxy and EPIKOTE binder 04695-1/EPIKURE 05490A curing agent for Class A composite parts that are made with gap impregnation RTM.

Clean wet-filament winding machine

Mouldlife Ltd.'s (Suffolk, U.K.) and Pultrex Ltd.'s (Essex, U.K.) new clean wet-filament winding technology made its debut at the show. Unlike traditional filament winding systems, the Mouldlife/Pultrex machine passes fibers through a closed resin dispensing unit (see photo) before winding. The dispensing unit, developed by CTM Ltd. (Barnsley, South Yorkshire, U.K.), automatically draws the resin and hardener, in the required stoichiometric ratio, from individual bulk reservoirs. Because resin is mixed and delivered at the machine, fast-cure resins can be used. The machine also features a modular fiber-bundle spreading station that maximizes the bundle width in preparation for winding. The companies say up to 80 percent less solvent is used, compared to wet baths, with an equivalent reduction of mixed resin waste. The unit is available as a retrofit for filament winding machines that are already on the market, and the technology is applicable to pultrusion. (See Fig. 4.)

Composites design software

MSC Software Co., a subsidiary of e-Xstream engineering (Mont-Saint-Guibert, Belgium), released version 4.4.1 of its Digimat suite of software products for composites design and engineering. Digimat consists of six modules: Digimat-MF (nonlinear behavior prediction), Digimat-FE (materials FEA), Digimat-MX (model storage and exchange), Digimat-CAE (interface to structural FEA codes), Digimat-MAP (data mapping) and Micross (honeycomb sandwich panel design). New features in this release include the following:

- Modeling of long fiber thermoplastics and woven composites.

- Matrix-based fatigue model.

- Periodic boundary conditions for unidirectional composites.

- New material data from Evonik and SABIC.

- Easier import of engineering data.

- GUI-based reverse engineering.

- Interface to injection-compression molding.

- Coupled analyses with thermoelastic materials.

- Cross mapping from 3-D volume to 2-D shell meshes.

Flame retardant filler for RTM resins

Nabaltec AG (Schwandorf, Germany) introduced a viscosity-optimized flame retardant filler designed to achieve the highest performance possible in resin transfer molding (RTM) applications. Apyral 44 aluminum tri hydroxide (ATH) is characterized as a fine product that will not interfere with low resin viscosity in fast infusion processes. It features optimized filtration behavior, results in good part surface quality and contributes good flame retardance. High loadings are possible, and Nabaltec says it has shown that this product improves flow, compared to other ground hydrates in unsaturated polyester resin composites.

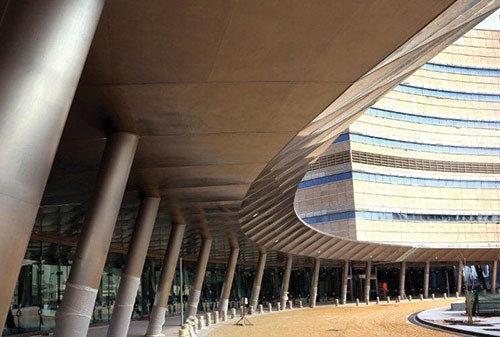

Finished sandwich panels

Nidaplast (Thiant, France) introduced two new ranges of finished sandwich panels, called Nidalite and Nidaskin, a company first. Nidalite is a range of high-strength, all-aluminum (core and skins) panels for rail, automotive and building applications. Nidaskin is a tailored product of finished panels that can be customized; it incorporates polypropylene honeycomb core and skins of different materials for composite structures that require a finished surface. The company also introduced a range of Nidaplast 8FR fire-retardant panels.

Eco-friendly cobalt polymer accelerator

Pergan GmbH (Bocholt, Germany, and Marshall, Texas) launched Pergaquick CP, a reportedly nontoxic and nonhazardous cobalt polymer accelerator product line, as an alternative to cobalt octoate (cobalt 2-ethylhexanoate), which has been classified as a carcinogenic chemical. Pergan says the new accelerators are based on a “forward-looking cobalt polymer.” The cobalt can be bound into a high-molecular-weight matrix called cobalt polymer. This decreases its bioavailability yet safeguards its curing performance. Moreover, cobalt polymer is exempt from registration, according to REACH, the European chemical regulatory agency. Even when REACH eventually addresses polymers, Pergan sees Pergaquick CP products as a long-term solution. According to Pergan’s six-month study, the new polymer accelerators can be replaced 1:1 (metal-to-resin ratio) in comparison to classic cobalt accelerators (the Pergaquick C product line). Several hundred curing tests have been done with ketone peroxides (MEKP, AHP, CUHP) and several common unsaturated polyester and vinyl ester resins. The dosage will be the same as that of comparable classic products. The exception is CP40, with a maximum of 4 percent cobalt, which must be converted by a factor of 2.5 because Pergaquick C100 has 10 percent cobalt.

Direct-injection RTM

Phoenix Equipment Co. (Memphis, Tenn., and Largo, Fla.) exhibited a new resin transfer molding (RTM) system, including the Phoenix 8000 internal mix gun and pump that reportedly has the highest output in the industry. With an attachment for direct injection into the mold, the system can be configured for polyester or epoxy, says the company. The RTM system is capable of delivering 28 liters/7.4 gal per minute and is targeted to large, high-volume applications, such as wind turbine blades and boat hulls.

Compression router eliminates splintering

Sandvik Coromant (Amsterdam, The Netherlands, and Fair Lawn, N.J.) introduced a new production compression router for carbon fiber composites and other composites where splintering is a common problem. The design of its CoroMill Plura compression end mill combines positive and negative helix angles and offers six effective cutting edges. The unit’s microgeometry is said to allow for close tolerances (less than 4 µm) and high material removal rates. The router is suitable for the automotive market sector and is recommended for use with a minimum material thickness of 6 mm/0.236 inch. Sandvik suggests conventional up milling because it results in less vibration. The company also recommends that users keep the split line in the middle of the material, and users should remember that when the tool cuts across the fibers on the top or bottom surface, there is more splintering than when the tool cuts along the fiber direction.(See Fig. 5.)

MMA structural adhesive

Scigrip Smarter Adhesive Solutions (Durham, N.C.), which combines the structural adhesive brands Weld-On, Holdtite and Macroplexx, highlighted its SG600 enhanced methyl methacrylate (MMA) structural adhesive. Suitable for bonding difficult substrates, including dicyclopentodiene (DCPD), without time-consuming preparation, SG600 is cold curing, with adjustable cure time and rheology that is compatible with robotic applications, and it reportedly produces tough, fatigue-resistant bonds thanks to the product’s elongation. Company president John Reeves told CT that he sees growth for the company in composites, particularly in automotive and transportation sectors, where adhesives play a role in lightweighting.

Low-styrene gel coat

Scott Bader (Wollaston, Northamptonshire, U.K.) premiered its new ultralow styrene content gel coat, Crystic Ecogel S1PA. The sprayable gel coat, which has been independently laboratory tested and reportedly proven to cut total styrene emissions by more than 55 percent, has been beta tested by customers, including wind turbine blade maker LM Wind Power (Kolding, Denmark). LM reports no loss of performance and a greatly improved work environment. Also on display was a new vinyl ester spray tooling gel coat, Crystic Gelcoat 15PA, with superior glass retention.

Spread-tow and noncrimp fabrics

Sigmatex UK (Runcorn, U.K.) introduced sigmaST, a spread-tow fabric available in 50g/1.76 oz and 75g/2.65 oz per ply areal weights, with a heavier 100g/3.53 oz per ply version also in development. The spread tape width is 16 mm/0.63 inch, and fabrics are woven with a new “state-of-the-art, high-output production process” to form a near-zero-crimp fabric. Narrower tapes are in development, says Andrew Ball, lead development engineer for multiaxial fabrics at Sigmatex. The company also showcased sigmaRF, a recycled/reclaimed carbon fiber noncrimp multiaxial (±45°) flexible fabric woven from 55-mm/2.2-inch recycled carbon staple fibers blended with a thermoplastic fiber. The fabric contains about 48 percent carbon by volume. It has significantly lower environmental impact than virgin carbon fiber-based materials. The fabric is targeted to the automotive market, primarily for nonstructural parts made with standard thermoplastic processes, where the surface finish isn’t an issue. (See Fig. 6.)

A first: PVC composites

SolVin, the vinyls production member of the Solvay Group (Brussels, Belgium), reported that it has developed technology that allows for the production of what constitutes the world’s first polyvinyl chloride (PVC) composites. In addition to its mainstay SolVin PVC resins, in 2006 the company launched its first-generation NanoVin, which contained PVC and nanoclay. In 2013, it launched the second-generation NanoVin, an eco-friendly, ready-to-use nanostructured (but without nanoclay) aqueous dispersion of PVC fortified with stabilizers and dispersants that can be formulated for long- or continuous-fiber impregnation. There are two composite technologies for which licenses on process patents are now available from SolVin.

The first is Autoflax, which consists of rigid plates with a thickness from 0.5 to 4 mm (0.02 to 0.16 inch) made from 45 to 55 percent continuous flax fibers with 45 to 55 percent PVC (SolVin or NanoVin grades). It can be produced by two different processes: flax fabrics are calendered with several layers of rigid PVC films, then the sandwich is thermocompressed at 180°C/356°F; or flax fabrics are coated with PVC latex and thermocompressed. The advantages of Autoflax include light weight, thermal insulation, soundproofing, good thermoformability, the ability to be glued or welded and UV resistance when coated. Potential applications include automotive interior trim and rear shelves; building door panels, ceilings, partition walls and furniture; and marine applications, such as decorative panels and partition walls. Autoflax also is expected to compete with epoxy/flax composites in sporting goods (such as tennis rackets), furniture and luggage.

The second is FibroVin consists of plates ranging in thickness from 0.6 to 1.4 mm (0.02 to 0.05 inch) made of 60 percent rigid SolVin PVC and 40 percent long-glass fibers (5 to 10 cm long). The production process is a combination of two technologies that were codeveloped with Fibroline (Lyon, France): dispersion of PVC dry blend into the cut glass fibers via electrostatic field (Fibroline); and gelation of the PVC dry blend without shearing (SolVin). The claimed advantages include excellent flame-resistance, high rigidity with high impact strength, good thermoformability, UV-resistance and the ability to be glued and welded. Target applications include electrical boxes; sandwich panel faceskins in transportation; partition walls; gypsum boards and other marine and building construction products; and reinforcements for profiles, plates and pipes. (See Fig. 7.)

Global real-time process monitoring

Synthesites Innovative Technologies Ltd. (Piraeus, Greece) showed off its new global system for real-time monitoring of composites processes. Resin cure (Optimold), resin flow (Optiflow) and temperature are monitored with the same software (Optiview) using a variety of durable and disposable sensors. With special modules, it is possible to monitor, in real time, a resin’s Tg, degree of cure and viscosity and to identify faulty conditions, such as an incorrect mixing ratio or resin aging in the mold cavity, in the die, at the feeding lines or in the resin pot or bath. In one application, the industrial use of Optimold in high-speed resin transfer molding (RTM) production already has enabled a cure cycle time reduction of up to 40 percent. Optimold and Optiflow systems reportedly have been successfully used in RTM, Light RTM, vacuum infusion and pultrusion processes in aerospace, automotive, industrial and wind energy applications, as well as in R&D centers. These systems can be readily used in other processes, such as in autoclave curing, filament winding and compression molding of sheet molding compound (SMC), according to the company.(See Fig. 8.)

Thermoplastic matrix resins

New products on the TenCate Advanced Composites USA (Morgan Hill, Calif.) stand included TenCate TC925 FST, a polycarbonate-based fiberglass for the aircraft interiors market; MS-4J, a low-flame/smoke/toxicity (FST) thermoset molding compound for aircraft interiors; Cetex 1220, a polyetheretherketone (PEEK)-based thermoplastic unitape (rated at 50-ksi/X 344.7-MPa compression after impact); and TC275-1, a 30-day out time/21-day tack life out-of-autoclave epoxy that cures at 275°F/135°C with low moisture uptake. TenCate also touted the fact that it is now the exclusive distributor and toll manufacturer for 3M’s nanosilica-filled 3M Matrix Resins for tooling. These products reportedly feature low exotherm, good surface hardness, low coefficient of thermal expansion (CTE) and low spring back.

Core sealant, flow promoter

Core material specialist 3A Composites Core Materials (Sins, Switzerland) featured on its stand two products that came on the market in 2012 and, since then, have been fine-tuned. The first is SealPerf, a technology that consists of thermally sealed holes arranged in a regular square pattern on the surface of a foam core. When it is applied to 3A’s AIREX T90 and T92 polyethylene terephthalate (PET) foam core, it provides a smooth hole surface that minimizes resin absorption and, thus, improves flow. 3A says that contrary to conventional wisdom about drilling holes in thick substrates, this technology can be applied without limitations to all sheet thicknesses. 3A also emphasized BALTEK Banova, a customizable veneer-based balsa material that can be used as core material and as a standalone panel in plywood applications. (See Fig. 9.)

E-CR glass rovings for thermoplastics

Fiberglass manufacturer 3B-the fibreglass co.’s (Battice, Belgium) new E-CR glass roving, SE4740, is designed for acrylic resins. It reportedly enables the manufacture and production of glass-reinforced polymethyl methacrylate (PMMA) thermoplastic composites. The sizing for the glass roving was developed with the help of Arkema (Paris, France) and Chomarat (Le Cheylard, France). The fiber is said to provide good processability in weaving and knitting processes and is compatible with Arkema’s Altuglas acrylic resin system. It’s also compatible with thermoplastic resin transfer molding (RTM) and vacuum-assisted resin infusion (VARI).

3B also featured on its stand a composite leaf spring molded with epoxy/E-CR glass that is designed for use on Daimler, Volkswagen and Mercedes-Benz vans in Europe. The leaf spring offers an 80 percent weight savings, compared to traditional steel springs (26 kg vs. 5 kg/57 lb vs.11 lb), and it provides excellent fatigue-resistance.

Large industrial microwave system

Vötsch Industrietechnik (Reiskirchen-Lindenstruth, Germany) introduced what is said to be the world’s largest industrial microwave curing system, with a working chamber volume between 750 liters and 7,000 liters (26.5 ft3 and 247.2 ft3). The VHM Hephaistos system is reportedly the first successful development of microwave technology on a large-scale, mature industrial engineering level. The company says that with this system it is possible to quickly cure carbon fiber composite parts and structures for automotive and other applications. The Hephaistos system requires no additional pressure and involves only inertia-free heating of the component itself — the oven is no longer actively heated. The system thus generates heat at the fast rate associated with microwaves but with low energy consumption. According to Vötsch, the Hephaistos oven offers very short cycles compared to heating carbon fiber composites in conventional autoclave ovens (4 to 5 hours vs. 10 to 15 hours) and uses 30 to 35 percent less energy. (see Fig. 10.)

Novel low-profile additives for room-temperature processes

Wacker Chemie (München, Germany) highlighted two new low-profile additives (LPAs) for room-temperature processes. As the latest additions to the Vinnapas range of polyvinyl acetate (PVAc) solid resins for optimized nonshrink surfaces, they have been shown to reduce the shrinkage of unsaturated polyester resins to less than 0.05 percent. The first is Vinnapas LL8588. The photo shows that fiber print-through is evident when no additives are used (left), but Vinnapas LL8588 enables a smooth Class A surface (right). The additive boasts a novel polymer architecture composed of PVA and polystyrene (PS) segments. The resulting block polymer not only has a low viscosity in the liquid resin formulations and keeps shrinkage in check during cure, even at room temperature, but also ensures that the finished product has low water uptake. The product was developed for semiautomated, low-emissions infusion processes, where it is said to promote rapid resin infusion and boost production efficiency by eliminating the need for intermediate layers while safeguarding a consistently high level of quality. It is suitable for complex composite parts in automotive or boat and yacht applications.

The second is Vinnapas LL 8251, a copolymer of vinyl acetate and crotonic acid. Because its viscosity is similar to that of saturated polyesters, it is said to be easy to process, even at high fiber and filler contents. Formulations based on saturated polyesters have a tendency to yield end-products of reduced rigidity and strength. In contrast, LL8251 offers effective shrinkage control combined with very high rigidity. The very good mechanical properties are said to lead to stable molded composite parts with extremely smooth Class A surfaces, which, in addition to their flat structure, offer excellent gloss and consistently high product quality. Aside from typical applications in the automotive sector, it has potential for use in composites for construction applications, such as windows, doors, industrial profiles and railings.

Static materials testing machine

Zwick GmbH’s (Ulm, Germany, and Kennesaw, Ga.) new Allround-Line testing machine was described as poised to set a new standard in static materials testing. This one modular tester reportedly covers 21 types of tests and meets the requirements of 115 standards over a wide temperature range. It is said to be ideal for composites whose properties depend on fiber alignment, the fiber, the matrix and the fiber/matrix interface. This machine is available with a force range starting at 5 kN and, depending on the requirements and desired force range, in flatbed or column format. The machine’s patented hollow-profile or classical column guides are said to guarantee maximum stiffness and precise crosshead guidance, providing a basis for accurate, traceable test results. The core of the Allround-Line is the new testControl II control electronics, said to provide precise, reproducible test results. The key features include new drive technology, high measured-value acquisition rates, modular design and a high safety standard. (See Fig. 11.)

Related Content

Composite resins price change report

CW’s running summary of resin price change announcements from major material suppliers that serve the composites manufacturing industry.

Read MoreA digital twin to validate SMC performance in suspension structures

High-fidelity, anisotropic behavior material card, integrated with process simulation, structural FEA and validated with CT and physical tests enables optimization proven in award-winning SMC suspension knuckle.

Read MoreDieffenbacher highlights Fibercut system for increased productivity

Dieffenbacher’s fully automated cutting and stacking system enables automated SMC processing applications.

Read MoreImproving carbon fiber SMC simulation for aerospace parts

Simutence and Engenuity demonstrate a virtual process chain enabling evaluation of process-induced fiber orientations for improved structural simulation and failure load prediction of a composite wing rib.

Read MoreRead Next

Class A CFRP body panels: Six-minute cure

Gurit CBS-based laminate/process combo mints parts with twice the thermal performance in one-sixth the time.

Read MoreCW’s 2024 Top Shops survey offers new approach to benchmarking

Respondents that complete the survey by April 30, 2024, have the chance to be recognized as an honoree.

Read MoreComposites end markets: Energy (2024)

Composites are used widely in oil/gas, wind and other renewable energy applications. Despite market challenges, growth potential and innovation for composites continue.

Read More

.jpg;maxWidth=300;quality=90)