Inside a CAMX session on composites recycling

CW technical editor Sara Black reports on the what some of the composites industry's leading recycling thinkers have to say about carbon fiber reclamation and re-use.

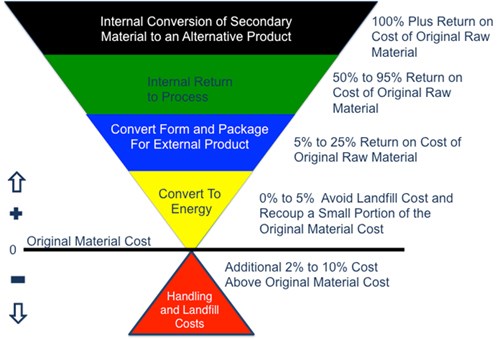

Polystrand's hierarchy of value associated with waste re-use.

At the recent CAMX show in Orlando, Fla., I got the chance to experience being on the podium side of the show. I was asked by session leaders Mark Janney of MIT RCF and Dr. Brian Pillay of the University of Alabama at Birmingham to participate in a Green Composites track, with the focus on recycling and re-use of composites. I was asked to speak on the topic of life cycle analysis (LCA), based on an article I had written for CompositesWorld.

For my part, I relied on my previous research for that article, and revisited the sources I had spoken to originally to make sure no significant changes had occurred in the interim, while adding new information. The experience was a little terrifying, but ultimately, illuminating, because it made me appreciate the amount of thought, discussion, experimentation, analysis and sheer hard work that the other session participants went through to prepare their technical papers and presentations. The Green Composites session on Thursday in Room 222A at the Orange County Convention Center personified a whole lot of research and development investment, directed at tackling the fairly intransigent problem of recycling of composites, particularly thermoset composites. Here are some highlights from a few of the presenters.

Being able to recycle production waste and end products was one of the primary reasons that Ed Pilpel, the president of Polystrand, launched the thermoplastic material company a decade ago, as a subsidiary of thermoset fabricator Gordon Holdings Inc. Citing the “abandoned boats in the backyard” as an impetus for addressing composite waste and adopting a more sustainable business model, his presentation, “Continuous Fiber Thermoplastic Composites and Recycling Alternatives,” included an interesting graphic (above) that clearly illustrates a hierarchy of value associated with waste re-use. He went on to discuss a project undertaken with the Materials Processing Applications Development (MPAD) center at the University of Alabama Birmingham (UAB), where an experiment was designed to test sample plaques made with Polystrand waste tape material mixed with new nylon resin. Tapes were chopped or shredded and mixed with dried resin, at varying fiber volumes, and then compression molded. While the experiment showed some unexpected variations in strength and modulus of the molded test plaques, depending on how the scrap material was handled and molded, nevertheless it proved that it is possible to collect and, with some value-added preparation, create a new molded product — the trick is finding a viable end user for the product, and maintaining consistent part quality.

Presenter Pete George of Boeing touched on some of the major themes of composites and recycling, with his presentation entitled “Challenges to Successful Implementation of Composites Recycling, and Suggested Solutions.” There’s no question that carbon fiber composites use has grown dramatically over the past three decades, and George showed an interesting slide, with fossil fuel use on the Y-axis and flight distance on the X-axis, that clearly illustrated that with more flight miles, transport aircraft made with carbon composites burn significantly less fuel over time, compared to traditional aluminum craft. The striking life cycle efficiency of carbon composites justifies its use in aerospace, and the performance requirements of aerospace composites in turn justifies the use of stiffer, stronger grades of carbon, with a higher price premium. He also pointed to data that show that the energy needed to recover carbon fiber is one-tenth that needed to make new, virgin carbon fiber. That energy savings, coupled with the higher properties of aerospace fiber, would seem to make recycling of Boeing’s, and other aircraft OEMs’, carbon fiber waste streams a logical endeavor.

And, George backed up that conclusion with data generated with partners MIT RCF and RTP Co. Several types of reclaimed fiber were included in the study, including dry intermediate modulus carbon fibers recovered from textile scrap by MIT RCF, and T800 fibers derived from toughened carbon prepreg scrap using a pyrolysis process. When these short yet high-performance fibers are compounded with thermoplastics in a range of fiber loadings, testing shows superior performance compared to conventional injection molding compounds. That is, the recovered aerospace carbon fiber waste performs better than virgin standard modulus carbon fiber in typical molding compounds, which certainly offers an incentive for recycling these wastes. And, said George, at low loading levels of 10 to 20 weight percent, the waste carbon compounds can compete with 30 percent glass-filled compounds on a performance basis, offering the potential for a 12 to 14 percent weight reduction in a part. He cautioned, however, that current methods for recovering fibers from prepreg and cured laminates, in particular pyrolysis, tends to reduce fiber performance and the resulting “fluffy” fibers aren’t easily conveyed and metered during compounding. So, much more needs to be done in the area of economical fiber recovery as well as waste material segregation to isolate these high-performance wastes.

Why not make composites easier to recycle from the get-go? That was the message delivered by Rey Banatao of Connora Technologies, in his presentation, “Recyclable by Design: A Chemical Approach to Recyclable Epoxy Composites.” His company has developed high-performance epoxy curing agents called Recyclamines that can be combined with any di-epoxide molecule in standard part processing. The chemistry creates “cleavage points” in the molecular chains, so that the cured thermoset can be broken down, in the presence of an acid compound, into a reuseable thermoplastic. Reinforcements can be recovered without damage in their original form and easily recycled.

And there was much more covered during the session, all aimed at addressing ways to get composites recycling up and running. So how did all of this tie into my LCA presentation? Well, if we can calculate the energy embodied by composites, and the impacts they cause, throughout their entire life, and if we can use recycled content to help mitigate those impacts and reduce that energy, composites start to look pretty “green” compared to our competition, usually steel and aluminum. Life cycle data can prove that composites represent a sustainable material choice because of their high strength and lower weight throughout their useful life.

Related Content

Materials & Processes: Resin matrices for composites

The matrix binds the fiber reinforcement, gives the composite component its shape and determines its surface quality. A composite matrix may be a polymer, ceramic, metal or carbon. Here’s a guide to selection.

Read MoreMaterials & Processes: Composites fibers and resins

Compared to legacy materials like steel, aluminum, iron and titanium, composites are still coming of age, and only just now are being better understood by design and manufacturing engineers. However, composites’ physical properties — combined with unbeatable light weight — make them undeniably attractive.

Read MoreNovel dry tape for liquid molded composites

MTorres seeks to enable next-gen aircraft and open new markets for composites with low-cost, high-permeability tapes and versatile, high-speed production lines.

Read MoreCryo-compressed hydrogen, the best solution for storage and refueling stations?

Cryomotive’s CRYOGAS solution claims the highest storage density, lowest refueling cost and widest operating range without H2 losses while using one-fifth the carbon fiber required in compressed gas tanks.

Read MoreRead Next

Composites end markets: Energy (2024)

Composites are used widely in oil/gas, wind and other renewable energy applications. Despite market challenges, growth potential and innovation for composites continue.

Read MoreFrom the CW Archives: The tale of the thermoplastic cryotank

In 2006, guest columnist Bob Hartunian related the story of his efforts two decades prior, while at McDonnell Douglas, to develop a thermoplastic composite crytank for hydrogen storage. He learned a lot of lessons.

Read MoreCW’s 2024 Top Shops survey offers new approach to benchmarking

Respondents that complete the survey by April 30, 2024, have the chance to be recognized as an honoree.

Read More