HPC turns 20

Celebrating two-decades of composites advocacy.

High-Performance Composites magazine was born this month 20 years ago. This is a remarkable milestone for any business, but it is particularly so in HPC’s case for two reasons. First, the publishing business is as famous for the quantity of its failures as it is for the quality of its successes, particularly in the trade publishing sector. The fact is, magazine titles come and go with astonishing rapidity. To push one past two decades is a feat in and of itself. Second, despite the fact that composites have been manufactured and in use for more than 100 years, this remains a relatively small — albeit growing — market.

A magazine like HPC survives exclusively on advertiser support, thus the larger the pool of potential advertisers, the greater the odds it has a long publishing life. HPC’s pool of advertisers, at its inception and for many of its formative years, remained relatively small, which leaves little room for error in the form of bad business decisions, economic downturns or both.

What muscles a trade publication through the lean and challenging times is usually strong leadership and a consistent commitment to editorial quality. This means that job number one is to serve the reader. If that is done well, all else will follow. In that regard, HPC began well. And what followed were 112 issues of HPC.

In the beginning

It’s natural, on this birthday, to look back at issue one of HPC for some perspective on how the composites manufacturing industry has evolved — or not, as the case may be.

HPC was launched by Ray Publishing Inc., owned by Judy Ray Hazen, in Denver, Colo. She had worked at one of the composites industry’s first magazines, Advanced Composites. That title was sold in 1992 to another publisher who, it was soon apparent, did not have the passion or commitment to the industry to keep it going. When it finally folded, Hazen saw the obvious publishing hole in the market and moved quickly to fill it with HPC.

The American economy of 1993 was not very robust — certainly not a suitable maternity ward in which to bring a new magazine to life. Bill Clinton had assumed the presidency in January of that year, and the economic improvement on which he’d campaigned to defeat George H.W. Bush (“It’s the economy, stupid”) had not yet been implemented. Further, the first Gulf War was winding down and defense spending was waning — a fact referenced several times in that inaugural issue of HPC.

Hazen, in her first editorial, titled, “We thought it over and decided to stay,” recounts phone calls from concerned friends in the composites industry: “You’re starting a new magazine ... in this industry? At this time? Are you sure you’ve thought this through?” Well, it turns out she had: “In short, we are enthusiastic about composites, we have thought it through, and we believe we can make a significant contribution to the industry.”

The more things change . . .

Reading through the premier issue with the benefit of 20 years of hindsight is a lesson in the timelessness of some challenges that face the composites industry.

The late, venerable Bill Benjamin, the helmsman at Composite Market Reports and a guest columnist in that first issue, noted that “the aerospace industry is in a tailspin ....” He hoped that idled aerospace and composites facilities could find new work to replace that which had been lost. In a now familiar refrain, he counseled diversification and suggested that they turn their eyes to American infrastructure, which “is in dire need of repair, refurbishment and outright replacements.”

In the News section, there’s a short report about how American Cyanamid had recently spun off a majority stake in its Piedmont, N.C.-based Cytec Industries chemical business, following Cytec’s acquisition of the Narmco business unit of BASF. The article concludes that Cytec “has been trying to become less dependent on aerospace markets in the U.S.” Interestingly, diversification was cited as one reason why Cytec acquired U.K.-based carbon fiber specialist Umeco in 2012. Still diversifying. Still growing.

One of the first issue’s feature articles, written by Debbie Stover, is a primer on designing composite structures that will be made via resin transfer molding (RTM). It notes that “RTM parts have so far been designed almost exclusively through the ‘empirical approach’ — otherwise known as trial and error.” The treatise that follows covers fiber orientation, ply sequencing, compaction, cure kinetics, heat transfer, resin models, fiber models, viscosity and fiber volume fraction and much more. Its observations are as timely today as they were in 1993.

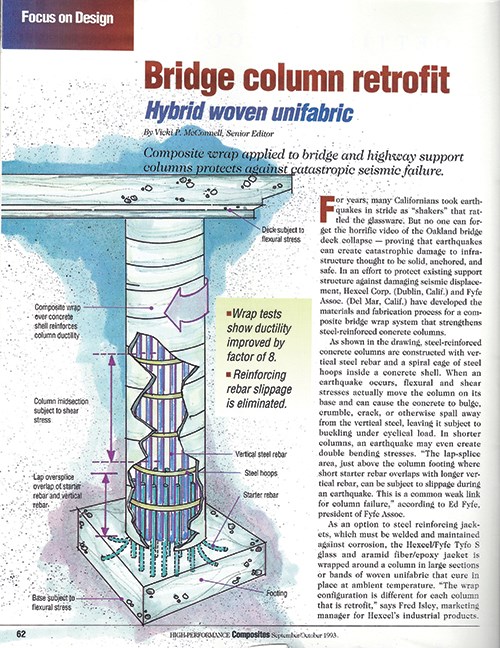

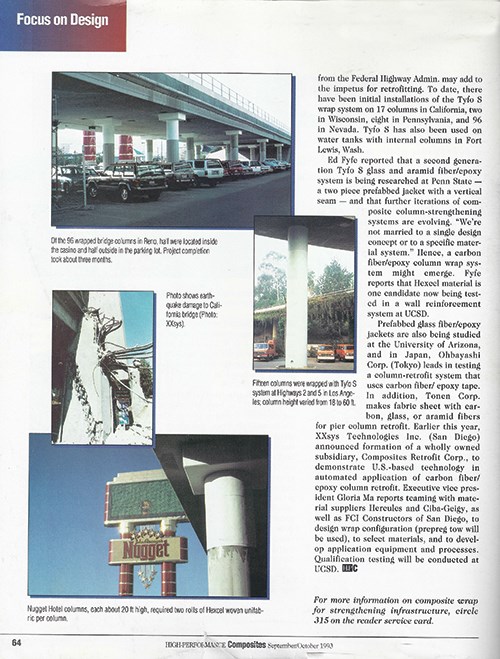

Also in that issue was HPC’s first Focus on Design article. Written by Vicki McConnell, it featured a composite wrap applied to several concrete bridge and highway support columns in earthquake-prone regions. The wrap technology, developed by Hexcel (Stamford, Conn.) and San Diego, Calf.-based Fyfe Co. LLC, consisted of a glass and aramid fiber/epoxy jacket wrapped around the columns and cured at ambient temperature. Ironically, this unlikely, nonaerospace application — not the type that might appear in HPC today — was one reason why Hazen started sister publication Composites Technology two years later. But if the test of time elevates a project’s importance, then it’s worth noting that those repaired columns still stand today (see photos).

Some things do change

The other feature article focused on composite pressure vessels for compressed natural gas (CNG) storage in cars and trucks. It surveyed work then in progress, done by Alcoa Composites, NGV Systems (both now defunct), Structural Composites Industries (now Worthington Cylinders), Brunswick Composites (which became Lincoln Composites, then Hexagon Lincoln), Compositek Corp. (which became Kaiser Compositek, then was bought by United Defense Industries and, later, BAE Systems Tensylon HPM Inc.), Spyro-Tech (founded by Brian Spencer of Spencer Composites Corp.), Amalga Composites Inc. (still around, specializing in tubing and rollers), Arde Inc. (still around) and Aerojet Rocketdyne (now Aerojet Rocketdyne).

Notably, that article, also by McConnell, cited industry data that boldly estimated the global fleet of CNG-powered vehicles would, by 2010, number 4.7 million. This turned out to be a vast underestimate. The U.S. Department of Energy’s Alternative Fuels Data Center says it was actually closer to 14 million.

Another news article cited a Freedonia Group Inc. (Cleveland, Ohio) report that said U.S. demand for carbon fiber would grow at 8.3 percent per year to an annual total of 5,500 metric tonnes (more than 12.125 million lb) through 1997. “Despite solid growth in product sales,” it said, “carbon fiber producers are losing money because prices are being cut to remain competitive or to attract new market applications.” By 2003, 10 years later, global carbon fiber capacity had reached 30,000 metric tonnes (almost 66.14 million lb). Today, global capacity has reached more than 120,000 metric tonnes (264.55 million lb). By 2020? It’s expected to top 160,000 metric tonnes (352.74 million lb) and might, if some predictions hold, exceed demand. That means carbon fiber producers might, once again, be casting about for new applications.

The next 20 years

Where will HPC be in 2033? If the trajectory of the past 20 years holds, the future looks bright. But HPC can’t rest on its laurels. Success relies on HPC’s continued ability to meet your information needs — and do so by means of an ever-broader range of media. In 1993, HPC was strictly a publishing enterprise — a printed magazine mailed bi-monthly to 20,000 composites professionals. Today, it’s part of a larger group of CompositesWorld media: HPC and sister CT — print and digital versions — a Web site, a weekly e-newsletter, conferences, Twitter, LinkedIn and Facebook. And it’ll go wherever else the Information Age takes it. As it goes, the mission statement that guided Hazen as she wrote her first editorial will be as pertinent as ever: “Our first job is to monitor advanced composites usage as the markets evolve, and pinpoint key individuals like you who need technical information. Second, we must make your job easier by delivering the right information in the clearest possible manner. To that end, we welcome your suggestions and comments.”

Related Content

PEEK vs. PEKK vs. PAEK and continuous compression molding

Suppliers of thermoplastics and carbon fiber chime in regarding PEEK vs. PEKK, and now PAEK, as well as in-situ consolidation — the supply chain for thermoplastic tape composites continues to evolve.

Read MoreFrom the CW Archives: Airbus A400M cargo door

The inaugural CW From the Archives revisits Sara Black’s 2007 story on out-of-autoclave infusion used to fabricate the massive composite upper cargo door for the Airbus A400M military airlifter.

Read MoreMFFD thermoplastic floor beams — OOA consolidation for next-gen TPC aerostructures

GKN Fokker and Mikrosam develop AFP for the Multifunctional Fuselage Demonstrator’s floor beams and OOA consolidation of 6-meter spars for TPC rudders, elevators and tails.

Read MoreMaterials & Processes: Tooling for composites

Composite parts are formed in molds, also known as tools. Tools can be made from virtually any material. The material type, shape and complexity depend upon the part and length of production run. Here's a short summary of the issues involved in electing and making tools.

Read MoreRead Next

HPC's 20th Anniversary: Not just a magazine, but a mission

On the occasion of HPC's 20th Anniversary, HPC's managing editor Mike Musselman recalls his early days on staff, the things that have changed, and those that haven't.

Read MoreHPC's 20th Anniversary: Thanks to HPC’s charter advertisers

Every trade publication lives and dies by its advertisers, and those who had the gumption to ante up for HPC’s premier issue are listed here and those who are still with us (see page numbers below) are gratefully recognized with the HPC 20th Anniversary Medallion.

Read MoreHPC’s 20th Anniversary: The senior technical editor looks back

In celebration of HPC's 20th Anniversary, HPC's senior technical editor Sara Black recalls the early days at HPC and the changes that she's seen.

Read More

.jpg;maxWidth=300;quality=90)