Composites repair

As more composite materials find a place on aircraft, boats, bridges and hundreds of other applications where part replacement is both difficult and expensive, OEM engineers are considering the repairability of structural and secondary composite components during the initial design phase of a project.

As more composite materials find a place on aircraft, boats, bridges and hundreds of other applications where part replacement is both difficult and expensive, OEM engineers are considering the repairability of structural and secondary composite components during the initial design phase of a project. Furthermore, now that composites have permeated primary aircraft structures — i.e. those required for flight including fuselage and wing components and doors — the quality of the repair, compaction of the repair patch and integrity of the bondline in adhesively bonded repairs becomes critical, driving a range of new technologies as well as pursuit of a standardized repair technician certification.

One the major issues in composite repair is time and labor. Manual repairs are time-consuming, and therefore, expensive. One development, in the past decade has been the rise of automated repair technologies and techniques. The goal of automated repair technology is not only to reduce time and cost but also the risk of human error.

There are several automated repair technologies in development, including a fairly small mobile system by Airbus (previously EADS Innovation Works, Ottobrunn, Germany), the Inspection and Repair Preparation Cell (IRPC) in the U.S., and a system using resin infusion by the German Aerospace Center (DLR, Stuttgart, Germany). For all of these systems, automated functions include creation of 3D digitized images of the repair surface, nondestructive inspection and evaluation (NDI/NDE) of damage, removal of damaged material and preparation of the repair area, construction of repair materials, and verification of the completed repair.

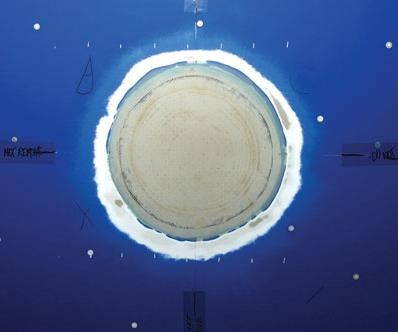

The system at Airbus uses a stereoscopic camera to create the 3D surface data, followed by phased array ultrasonic testing (UT) to determine the extent and degree of damage. Results are sent to engineers in the design office, who respond with computer numerical control (CNC) directions for damage removal via robotic milling and an appropriate repair design which then drives the digitally controlled creation of a precured composite repair patch. Airbus personnel explain that a hand-layed, wet layup patch that is cured on the repaired surface is neither appropriate nor currently approved and certified for aircraft primary structures. They concede that approach works fine for nonstructural parts like fairings, but does not reliably produce high-quality, load-carrying, composite primary structure repairs. A precured patch enables a much higher level of quality control. First, a repair patch tool is created from a 3D scan of the milled repair area surface, followed by automated tape laying and cure of the repair patch. Finally, the precured patch is applied to the fuselage with film adhesive, and the bond is cured using a local vacuum bag.

Begun in 1999 and publicly unveiled in 2005, the Inspection and Repair Preparation Cell (IRPC) is the ongoing work of a consortium of companies and championed by American GFM Corp. (AGFM, Chesapeake, Va.), a member of the GFM machine tool organization headquartered in Steyr, Austria). The IRPC is designed to integrate into a single, automated work cell a variety of tasks regularly performed manually by aircraft maintenance and repair organizations, or MROs (See "Learn More," at right). Where Airbus is using the ATOS high-resolution optical 3-D scanner, made by GOM mbH (Braunschweig, Germany), the IRPC utilizes Steinbichler Vision Systems’ (Plymouth, Mich.) T-SCAN 3D laser scanner. Next, laser shearography — via the ISIS system, also by Steinbichler — is used to provide a quick indication of areas that contain damage or defects, followed by local (secondary) NDI to determine more precisely the location, boundary and depth of the defects. The secondary NDI technology used is Terahertz NDI, provided by Picometrix LLC (Ann Arbor, Mich.), chosen because of its accuracy, resolution and speed of inspection. Using electromagnetic waves with wavelength between microwaves and the far-IR — a region called the “Terahertz Gap” — terahertz wavelengths penetrate through most materials, similar to X-rays, and can easily reveal imperfections such as voids, cracks, and density variations. However the radiation is non-ionizing and thus is completely safe. GFM equipment is used for automated scarfing (taper sanding) of the repair area and automated cutting of the repair patch plies. The actual cure and bonding of the repair patch is still complete manually, followed by final NDI for quality assurance.

The infusion-based automated repair system at DLR employs 3-D laser scanning of surface geometry integrated with CATIA CAD software (Dassault Systèmes, Vélizy-Villacoublay, France) to develop the repair scarf design, similar to the Airbus system. It also uses computer-controlled milling for damage removal. However, the DLR process also eliminates fabrication of tooling and a precured repair patch by using resin infusion to impregnate in situ a dry patch preform. DLR claims its method drastically reduces process complexity for curved parts and yields a patch with mechanical performance equal to that of state-of-the-art precured, or hard, patches. Microscopic evaluation reportedly showed a good bondline with no voids for infusion repair but identified voids in the hard patch. Tensile test results for both repair types were basically the same, achieving 80 percent total load recovery. Future developments will include miniaturization and improved mobility of machining as well as simulation and optimization of 3-D patch repairs.

Because the bondline between a patch and a repaired surface is so important, efforts are underway to optimize surface preparation. CleanLASER (Herzogenrath, Germany) claims it has developed a laser surface pretreatment for carbon fiber composites that enables superior structural bonded repairs, without the use of chemicals and abrasives and with no waste. An adapted laser and optical machining system were designed to be portable and mountable onto aircraft surfaces even in the field, enabling fully automated composite repairs with greater quality and reliability. The system was evaluated on actual parts and the company claims that ply-by-ply damage removal is possible and that the laser achieves surface energy activation that increases bond joint strength by up to 20 percent. Meanwhile, GKN Aerospace (Isle of Wight, U.K.) and SCLR Lasertechnik GmbH (SLCR) have developed a robotic machine that uses laser technology to remove damaged composite structure on aircraft. The new robotic cell, housed at GKN Aerospace’s composites research center in the U.K., replaces the time-consuming, manual grinding away of damaged structure with a precise, contact and vibration-free laser removal process. The company says that the automatically repaired structure can match the strength of current manually performed repairs and achieves that goal with greater consistency and, importantly, at a 60 percent cost reduction.

Another industry effort is the development of a Composite Repair Technician (CRT) certification to standardize and improve the level of individual repair skills in the industry. The system envisioned would be similar to the one already in operation for nondestructive inspection (NDI) technicians. A graduate of a certified composite-repair training program would take a written test at the certified school and then perform a practical repair exercise. The repaired structure would be shipped to an independent test lab for both NDI and destructive testing to verify the repair bond’s strength.

Composite repair training standards have already been developed by the Commercial Aircraft Composite Repair Committee (CACRC), a group comprising the Air Transport Association of America Inc. (ATA, Washington, D.C.) and the International Air Transport Assn. (IATA, Montreal, Quebec) as well as most international aircraft OEMs and airlines. Its standards-setting activities are overseen by SAE International (Warrendale, Pa.). SAE also administers quality assurance, accreditation and certification programs through its Performance Review Institute (PRI). Nadcap (Warrendale, Pa.) is the global cooperative program that PRI administers in an effort to improve quality assurance in the aerospace industry, working with companies to audit and certify that they meet specific industry standards. PRI conducted more than 4,000 Nadcap audits in 2010, 200 of which were done for companies that build composite parts. PRI is considering being the entity to which written and practical exam results for the CRT would be sent for review and would issue the CRT certification. Because it lacks the funding and personnel to support a mandate, the FAA would probably publish an Advisory Circular recommending, rather than requiring, that airlines and MROs internally require Level 3 or Level 4 composite repair certification for technicians who perform structural composite repairs to aircraft such as the Boeing 787 or Airbus A350. This would put composite repairs on par with welding and NDI technicians for certain airframes and components. However, current composite repair technicians would have to be grandfathered to make this system practical for airlines and MROs by avoiding the operational disruptions that would accompany an effort to certify already active crews.

Other composite components that require repair include heavy truck front ends and other automotive as well as marine products. Whether damage is minor or extensive, training and specific repair materials are available. A number of materials suppliers provide kits that contain low- or room-temperature curing adhesives and potting compounds formulated especially for onsite repair, along with low-quantity dry fiber or prepreg and vacuum-bagging materials. At least a dozen private training companies nationally offer from 1- to 10-day courses in composite repair.

The amount of composites used in the global automotive industry is still small compared to steel and aluminum. Carbon fiber-reinforced plastics (CFRP) have been confined mostly to racecars, supercars and high-end luxury vehicles. On the small number of high-end autos on which CFRP is used for body panels, those damaged hoods, deck lids/trunk lids, roofs, fenders and door panels are generally removed and replaced. Despite their cost, there is little economic incentive to attempt repairs on such parts, and this is unlikely to change in high-volume applications. However, as CFRP moves into more critical structural components on the chassis, repair is likely to be more desirable. The motorsports industry features a large number of companies who routinely repair CFRP structures in automobiles. Moldex Composites Pvt. Ltd. (Surat, India), has more than 25 years’ experience with advanced composites for Formula 1 (F1) and endurance sports-car racing. Using materials, methods and training from the aerospace industry, the company would repair predominately unidirectional laminates, for nonstructurally critical areas using patches approximately 1-mm/0.04-inch thick and extending 25 mm/1 inch beyond the damaged area. For structural areas that were more critical to suspension or driver safety, it would use large overlap joints for extra security and then conduct a proof load test (using either a simple torsion test or a push/pull test for suspension joints) and compare measurements against those recorded throughout the season for each chassis that was built. This was done to prove that, unlike repairs to a welded aluminum chassis, these CFRP repairs did not “soften” the structure. Moldex would continue to patch these cars and run them — sometimes as much as 10,000 miles (16,093 km) — until it was no longer worthwhile weight-wise to do so.

To support its 2011 launch of the two-seater, midengine Aventador LP700-4, Automobili Lamborghini SpA (Sant’Agata Bolognese, Italy) collaborated with Boeing and the Advanced Composite Structures Laboratory (ACSL), both located in Seattle, Wash., to develop a strategy for assessing the level of damage sustained by CFRP elements and then provide specialized field support to customers. The Aventador features a one-piece, all-CFRP monocoque coupled, front and rear, to rigid aluminum subframes, as well as extensive use of CFRP on vertical body panels, the rear engine decklid and the rear air scoops. The team established a strategy to determine whether to repair or replace pieces of a car if it becomes damaged, identifying zones that are more critical than others to the safe operation of the car. It then developed a repair strategy and a global repair network. A customer with a damaged Aventador would first have it towed to the nearest Lamborghini dealership or repair shop, where the car would be examined. Next, a damage report (containing written and photographic documentation) would be prepared and submitted, along with a quick claim, via Lamborghini’s Web-based portal. Experts within Lamborghini would examine the information and try to determine the extent of the damage. If necessary, they would send a technician from an external company specializing in nondestructive inspection (NDI) to provide ultrasound and thermography data using field-portable units. If the damage proved minor, then it would be repaired at the service center according to Lamborghini instructions. However, if Lamborghini determined the damage was to a critical chassis component, it would send one of its specially trained technicians, who understands both carbon composites and the vehicle’s engineering, to fix the car. The automaker calls this elite group its “flying doctors” — there are currently only four of them, worldwide — and says they are on call 24/7/365 to travel to any location where an Aventador’s composite structure has been damaged. Equipped with everything necessary to make an advanced-composite repair in the field, the technician makes a relatively straightforward patch or a more elaborate co-plate (cut from a large piece of carbon composite) used to strengthen the damaged zone. Because the vehicle combines a number of CFRP forms — including prepreg and RTM/braid on both Class A and non-Class A parts — the technician is prepared with all the materials that might be needed to fix whatever is damaged (see “CFRP repair: Aventador,” under "Editor's Picks"), including a hot bonder connected to two different heater blankets, each with its own controls, so two different materials with two different curing cycles can be repaired at the same time. Depending on the extent of damage, the repair might take between 1 and 14 days.

Composites are increasingly being used to repair structures built with other materials, such as bridge beams, bridge decks, parking garages and pipelines, including underground systems. A number of specialty contractors, such as Structural (Hanover, Md.) and Fyfe Co. LLC (San Diego, Calif.) use composite fabrics and precured reinforcement strips to add load capacity and strength to concrete floors and beams. Composites also can be used to repair product pipelines, such as natural gas and petroleum pipes at oil refineries and offshore platforms, and to rehabilitate underground storage tanks without the time and expense of excavation. A number of companies provide internal tank lining services, using various fiberglass products to meet the requirements for double-walled tanks and interstitial monitoring now in place.

Related Content

MoviTHERM opens in-house NDT lab

New inspection techniques, excitation sources and infrared cameras enhance feasibility study capabilities for customers in the composites industry.

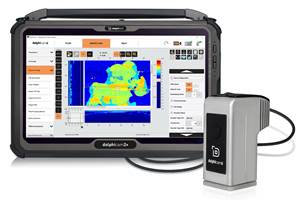

Read MorePortable digital ultrasonic imaging achieves in-service, field and manufacturing inspection

CAMX 2023: 2D array ultrasonic NDT for composites, metals and other materials is made possible through Dolpitech’s dolphicam and dolphicam2+ matrix transducer technology.

Read MoreLoop Technology develops robotic arm for wing box inspection

Part of an R&D project with Spirit AeroSystems, the seven-axis Bravura robotic arm automates inspection and sealing within small spaces like aircraft wing boxes.

Read MoreRobotic inspection systems maintain process efficiency, productivity

CAMX 2023: Matec Instrument Companies highlights its strong commitment to integrate automation technologies into its nondestructive ultrasonic testing equipment for increased scalability, flexibility, quality and consistency.

Read MoreRead Next

Automotive CFRP: Repair or replace?

As more carbon composites are used on structural car components, how will crash damage be assessed and repairs be made?

Read MoreFrom the CW Archives: The tale of the thermoplastic cryotank

In 2006, guest columnist Bob Hartunian related the story of his efforts two decades prior, while at McDonnell Douglas, to develop a thermoplastic composite crytank for hydrogen storage. He learned a lot of lessons.

Read MoreCW’s 2024 Top Shops survey offers new approach to benchmarking

Respondents that complete the survey by April 30, 2024, have the chance to be recognized as an honoree.

Read More

.jpg;maxWidth=300;quality=90)