Composites Refine Soap Box Derby Racers

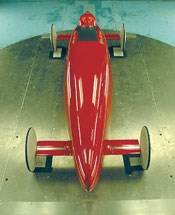

Starting with a molded kit, Masters racers add fiberglass to stiffen and streamline their vehicles.

Ryan Harrigan, at age 15, is a champion racecar driver. In his first race, at age nine, he placed in the top half of the field. He finished third in his second race. Today, the basement of his family's house holds more than 100 trophies from his racing career. That number may well double in a few years: Ryan's brother Sean began racing last year at the age of seven, and his goal is to win more trophies than his big brother.

Too young to hold a driver's license, the Harrigans race "Soap Box Derby" cars powered by gravity. Derby racing got its start in 1933, when newspaper photographer Myron "Scottie" Scott came across three boys racing homemade, engine-less cars down an inclined street in Dayton, Ohio, U.S.A. Scott's newspaper, the Dayton Daily News, sponsored a formal competition later that year, where 362 competitors and 40,000 spectators showed up. By 1935, the race attracted corporate sponsors and competitors from around the country, and had moved to Akron, Ohio.

Today, Derby racing is an international event. Akron-based International Soap Box Derby Inc. administers the All-American Soap Box Derby (AASBD), which establishes rules and licenses local race organizations. The world championship race is held each July in Akron. Competitors come from just about every part of the world, including Puerto Rico, Europe, Japan, the Philippines, South Africa and New Zealand. National Derby Rallies Inc. (NDR, Austell, Ga., U.S.A.) provides additional racing opportunities in sanctioned events held throughout the U.S. and Canada.

FROM SOAP BOXES TO FIBERGLASS

Although there is no record of an actual "soap box" car in the first race, early cars were built of whatever happened to be at hand, from orange crates to sheet tin. Most of the early rules set maximum dimensions and weight for the cars, but not much else. As the years went on, however, various rules were added, including requiring competitors to build their own cars and mandating the use of specific wheels and axles. In 1962, David Mann won the AASBD championship with a streamlined, fiberglass car. In 1976, the competition was divided into junior (Kit Car) and senior (Masters) divisions; while seniors built their cars from scratch, juniors were given kits to make construction easier. In 1982, nylon wheels reinforced with fiberglass replaced the standard metal wheels, which had become too expensive to produce. The current AASBD has three divisions: Stock, Super Stock and Masters.

Ryan Harrigan races in the Masters Division. Prior to 1999, Masters cars were built from scratch. Thin strips of wood were shaped over forms, and then covered with glass/epoxy to hold the shape, similar to the way many canoes and boats are built. According to Ryan's father Mike, it took 1,000 to 1,500 hours to build a winning car. Since few people had the time to build Masters cars, the division had dwindled to about 50 competitors by the mid-1990s.

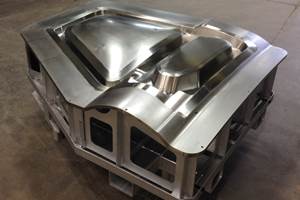

In 1999, AASBD introduced the Scottie Special, a new kit for the Masters division. The Scottie kit includes a four-piece fiberglass shell, molded by Monarch Plastic Inc. (Orrville, Ohio, U.S.A.), a wooden floorboard, axles, a steering and brake assembly, a racing helmet and assembly hardware. A Scottie can be built in as little as 80 hours, which is helping to fuel an increase in Masters entries. Jeff Iula, AASBD general manager, says that about 200 Scottie kits are now sold each year.

CUSTOMIZING THE SCOTTIE

AASBD rules allow the Scottie to be customized within certain limits, and successful racers will take full advantage of those options. The cars start the race from a ramp at the top of a hill. Each car must be ballasted so the total weight with the driver is 116 kg/255 lb, to within about 57g/2 oz. As a result, "all cars start with the same potential energy," says Mike Harrigan. "The car that most efficiently converts that potential to kinetic energy wins."

George Weissgerber, AASBD regional director for the mid-Atlantic states, distributes a Scottie construction manual on CD. While his manual covers the basics of assembly, he also provides extensive instructions for achieving optimal energy management. "Having a rigid structure is important to making a fast car," explains Weissgerber, "because energy isn't diverted into making the car vibrate." Although all cars must weigh the same, Weissgerber and other long-time competitors have found that moving a car's center of gravity as close to the plane of the axles and as close to the geometric center of the car as possible leads to a faster car.

Structurally, then, a good derby car will add material in order to increase stiffness, maximize weight, and lower the center of gravity by keeping the body, tail, and top as light as possible. The wooden floorboard and fiberglass shell form the primary structure of a derby car, so modifying these components will have the biggest effect on overall weight and stiffness. Strict rules that set minimum height, width, and girth (circumference), maximum length, and minimum ground clearance limit the dimensional modifications that can be made. The only modifications allowed to the floorboard, for instance, is rounding the bottom to within the minimum circumference and cupping out material for the driver's seat and feet. Although carbon fiber or similar materials are not allowed, fiberglass may be added, but only to the outside of the car body.

Weissgerber recommends wrapping the entire outer body with fiberglass fabrics, from one end of the cockpit opening to the other, around the bottom of the vehicle. The added glass improves overall stiffness while minimizing the added weight on the top of the vehicle. Next, additional plies are bonded to the bottom of the vehicle, adding bending stiffness and weight below the floorboard. Each ply is cut about 6.4 mm/0.25 inch shorter than subsequent plies, to provide a smooth taper. The number of bottom plies should be maximized in order to put as much weight as possible below the floorboard. The laminate thickness is limited by the minimum ground clearance. Sufficient margin must be left for the weight of other components, including the driver (which may change during the racing season or even during a single day of competition).

The added fiberglass layers are permanent, so it is important to determine the correct number of plies before construction begins. The calculation is not easy. The car designer must take into account the weight of both stock and custom components, the amount of material that rounding and cupping removes from the floorboard, the weight of foam and filler materials used for aerodynamic effects, and the geometry of the suspension system. Weissgerber's manual includes an Excel spreadsheet that calculates the maximum number of plies based on these factors.

ASSEMBLING THE SHELL AND FLOORBOARD

Vehicle assembly can begin after the fiberglass layup and other components have been designed. The outside of the shell might still have a coating of mold release, so it should first be washed with acetone and then scuffed with 40-grit sandpaper. Excess flash is ground off of the shell halves, and then the halves are taped together and placed on the floorboard. After adjustments are made for proper height, girth and hatch fitting, holes are drilled for temporary holding screws, and a hole is cut for the front axle access cover using a sabre saw and carbide steel bit.

At this point, Weissgerber recommends cleaning up the inside of the kit's composite shell with a palm sander and then finish sanding it with 320-grit sandpaper. This will leave some loose fibers that should be resealed with a thin coat of wax. Shell-to-shell and shell-to-floorboard joints must be sanded and cleaned to remove any gel coat in preparation for bonding.

The shell is bonded to a nailer strip on the floorboard using a paste epoxy such as AEROPOXY (PTM&W Industries Inc., Santa Fe Springs, Calif., U.S.A.) mixed with a filler such as milled fibers, then held in place with wood screws inserted through the holes drilled earlier. The shell halves are bonded using paste epoxy between the joints and two layers of fiberglass/epoxy on the outer surfaces of the joint. Many racers use West System (Gougeon Brothers Inc., Bay City, Mich., U.S.A.) laminating resin, but Weissgerber and Mike Harrigan recommend an aircraft-quality resin such as Poly Epoxy (Aircraft Spruce, Corona, Calif., U.S.A.) for improved structural properties. After the joints cure, the holding screws can be removed, the axle holes cut out, and the axles and driver test-fitted into the body.

Before the outer fiberglass wrap can be applied, the floorboard must be sanded to the proper contour, cleaned and sealed with a penetrating epoxy such as Rot Doctor (The Rot Doctor Inc., Seattle, Wash., U.S.A.). Templates for cutting the fiberglass cloth are created by laying a bed sheet over the vehicle body and cutting it to size. The plies are then applied using standard layup techniques. Fibre Glast Developments Corp. (Brookville, Ohio, U.S.A.) is a popular source of mixing equipment and other consumables among Derby builders. The Harrigans use three layers of unidirectional S-2 glass oriented to the length of the car (0° axis) interleaved between four layers of DBM-1708 biaxial knitted E-glass fabric oriented at ±45°, which account for the bulk of the laminate. The layup is finished with a 227g/8 oz veil cloth. The Harrigans buy their glass from Aircraft Spruce, and Fibre Glast also carries similar materials. After an initial room-temperature cure, the body should be postcured at 60°C/140°F to achieve maximum structural properties and to prevent any deformation when the vehicle heats up in the sun. The Harrigans use a plastic tent and electric space heaters as a post-cure oven.

AERODYNAMIC FINISHING

Top speeds in a Derby race reach 40 to 56 kmh (25 to 35 mph). Although aerodynamic effects at those speeds are relatively small, minor design changes can still have a big impact. A 0.001-second time saving translates into an additional 25.4 mm/1 inch lead, and many races have been determined by less than one inch.

The tail of the Scottie comes to a blunt end. This can be extended into a point, which is more aerodynamically efficient, by bonding a flat aluminum extension piece to the shell and then covering it with strips of fiberglass cloth and laminating resin to achieve a triangular cross-section. When installed properly, the extension should be aligned with the vertical and horizontal axes of the car, and protrude no further than the back edges of the rear wheels.

The hatch, one of the four fiberglass pieces supplied with the kits, must fit snugly into the top of the body. Reinforcing the hatch opening with wooden braces stiffens the opening, allowing for tighter tolerances. The shell will bow out from the weight of the driver, so ballast weights must be used when sizing the hatch to achieve the tightest fit. The hatch also must be extended with additional fiberglass so the hatch seam extends to the helmet cup, creating a clean, aerodynamic seal.

The helmet cup is part of the headrest, a complicated structure that locks the driver's helmet into position for safety and maximum visibility. The headrest frame also provides lateral stiffness to the vehicle body at the aft end of the hatch opening. The helmet cup is formed by placing the actual helmet into the plywood seat of the headrest, applying mold release to the helmet, and then laying up fiberglass and resin directly onto the helmet. The headrest tail, formed by laying up glass fabric over foam, provides a smooth, aerodynamic transition from the helmet cup to the vehicle body.

The final body shape is tailored with a skim coating of body filler such as Bondo (Bondo Corp., Atlanta, Ga., U.S.A.). The filler coat builds up areas where necessary to reach minimum dimension requirements, hides any print-through from the glass cloth, improves the aerodynamic shape in the transition areas and provides a good surface for the final paint job. Many racers have their cars professionally painted since paint schemes can be very elaborate.

Weissgerber developed his construction manual while helping the Harrigans build Ryan's car. Ryan was the National points leader in last year's NDR Masters Division, and had the second fastest elapse time in the 2000 AASBD. Weissgerber's son Johnny, whose car was built using the same methods, finished third at the 2002 NDR National Masters Championship, and third at the 2001 AASBD World Championship. The competition remains fierce, so both racers continue to look for new construction techniques that will give them the slight edge they need to win.

Related Content

CAMX 2022 exhibit preview: Composite Automation

Composite Automation is joined by Isojet Equipements and PCM/Lucas Industries, bringing solutions for every step of the composites manufacturing process to one booth.

Read MoreInnoptus Solar Team uses Jetcam software to optimize production of solar vehicle

The world title-holding, Belgium racing team is producing its tenth composites-intensive solar car using Jetcam Expert nesting software.

Read MoreSchmidt & Heinzmann camera system awarded 2022 AVK Innovation Award

“Pole Position” uses polarization properties to detect the positioning and orientation of carbon fibers during the cutting and stacking process, reducing waste and enhancing sustainability.

Read MoreHypertherm announces release of ProNest 2023 CAD/CAM nesting software

ProNest 2023 focuses on improving its automated Industry 4.0 functionalities and reducing cutting waste, ultimately giving users a more holistic operations perspective.

Read MoreRead Next

Composites end markets: Energy (2024)

Composites are used widely in oil/gas, wind and other renewable energy applications. Despite market challenges, growth potential and innovation for composites continue.

Read MoreFrom the CW Archives: The tale of the thermoplastic cryotank

In 2006, guest columnist Bob Hartunian related the story of his efforts two decades prior, while at McDonnell Douglas, to develop a thermoplastic composite crytank for hydrogen storage. He learned a lot of lessons.

Read MoreCW’s 2024 Top Shops survey offers new approach to benchmarking

Respondents that complete the survey by April 30, 2024, have the chance to be recognized as an honoree.

Read More

.jpg;maxWidth=300;quality=90)