March 2008 Issue

March 2008

Features

Featured articles from the March 2008 issue of CompositesWorld

Aircraft interior bins benefit from fast-heat, fast-cool tool

Airbus Industrie (Toulouse, France) wanted to cut cycle time off the production of interior storage bin doors for its A320 and A380 commercial airplanes and identified part cooling in the mold as the most likely source of potential time savings. The doors, about 1m long, are fabricated of a glass fiber prepregged with

Read More

Aligned discontinuous fibers come of age

Discontinuous but aligned carbon fibers are proving formable and formidable in high-performance, compound-curvature applications.

Read More

Automate or emigrate

Automated fiber and tape placement is not just a notion, but a real manufacturing strategy, and one being embraced by HITCO Carbon Composites.

Read More

Aviation Outlook: Composites in rotorcraft reaching new altitudes

One of the earliest markets for advanced composites, helicopter manufacture is and will continue to be a stronghold for industry growth.

Read More

Chemical vapor deposition of diamond material helps reduce cutting time, increase quality for JSF wing skins

Who wouldn’t give $105,000 to gain $222 million? Lockheed Martin Aeronautics Co. (LMAC, Ft. Worth, Texas) did and in the process was able to fabricate dimension-critical aerostructures more efficiently, more accurately, and faster. LMAC is a major components manufacturer for the F-35 Joint Strike Fighter (JSF), the

Read More

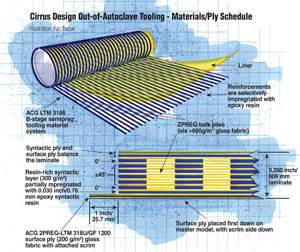

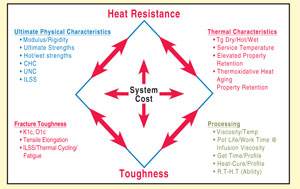

Formulating challenge: Creating better epoxies for vacuum-infused aerospace parts

More attention is being focused on fabricating processes for aircraft structures that can save time and money and improve efficiency while yielding high-quality parts. Historically, nearly all aircraft designers have assumed autoclave cure as the norm, despite the well-documented cost and time advantages of

Read MoreStartup struggles

A week before Adam Aircraft made the somewhat surprising announcement that it had run out of cash and couldn’t find anyone to lend it money, I found myself on the phone with one of the company’s composites design engineers. We were discussing trends in composites design for aerospace, aerospace design challenges, and

Read More

Testing Tech: Multiple-fastener, single-shear laminate bearing strength testing

Dr. Don Adams (Wyoming Test Fixtures Inc., Salt Lake City, Utah) follows up his HPC January 2008 discussion of double-shear testing of a single fastener while advice about testing multiple fasteners under single-shear loading conditions.

Read More