November 2008 Issue

November 2008

Features

Featured articles from the November 2008 issue of CompositesWorld

An open letter to the U.S. President-elect

Dear Mr. Obama or Mr. McCain, By now you have celebrated your hard-fought victory and are busy preparing to take office in January 2009.

Read More

Composites encourage design creativity in LSA aircraft

Manufacturers of small aircraft expand the private pilot’s options on the strength (-to-weight) and contourability of advanced composites.

Read More

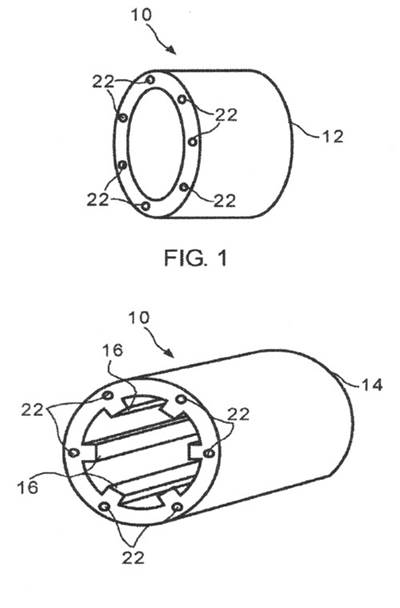

Composites stabilize space-based telescope

Composite Primary Mirror Backplane Support Structure to hold James Webb Space Telescope’s thermal stability within extremely tight 38-nm dimensional tolerance.

Read More

COMPOSITESWORLD Expo 2008 Showcase

The inaugural COMPOSITESWORLD Expo Conference and Exhibition draws participants from all segmentsof the industry, including many new faces.

Read More

MOM software solves debonding problem in manufacturing process

When Composites Atlantic Ltd. (CAL, Lunenburg, Nova Scotia, Canada) contracted to produce 10 types of parts for leading edge and rudder components and deliver them on a biweekly schedule to a key aerospace customer, trouble soon cropped up.

Read More

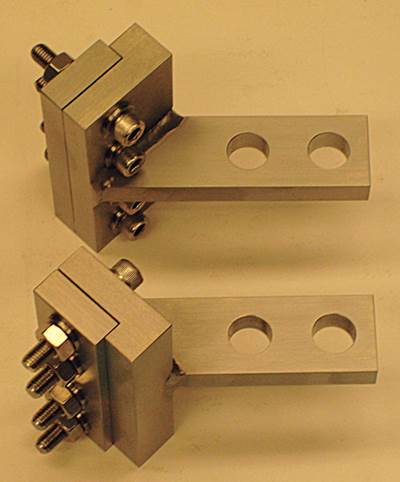

Through-the-thickenss tensile strength testing using a curved beam

The in-plane strength properties of a composite material, axial and transverse tension and compression and in-plane shear, are usually the first to be considered in design. However, through-the-thickness (interlaminar) strength properties cannot be ignored. Through-the-thickness tensile strength, in particular, can be critical to structural performance.

Read More

Unmanned rotorcraft passes stringent German Navy shipboard tests

CAMCOPTER’s high strength-to-weight ratio is made possible by composite materials.

Read More

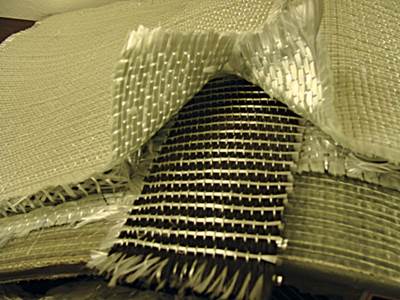

Wind Blade Manufacturing, Part I: M and P innovations optimize production

As demand for wind turbines reaches unprecedented levels, rotor blade manufacturers explore new production strategies, including automation and blade segmentation.

Read More

Wind Blade Manufacturing: Are thermoplastic composites the future?

In a market dominated by thermoset composites, some wind turbine blade manufacturers are actively pursuing new composite blade designs featuring faster-processing reinforced thermoplastics.

Read More

Wind Blade Manufacturing: Cost-efficient materials-based strategies

The wind blade’s four key elements — the root, the spar, the aerodynamic shell or fairing, and the surfacing system — have present unique manufacturing challenges that must be met with carefully selected composite material systems and molding strategies.

Read More