An Elegant Solution For A Big Composite Part

The rear pressure bulkhead for the Airbus A380 employs resin film infusion.

The manufacture of Airbus' (Toulouse, France) supersized A380 commercial transport presents some interesting challenges, as noted in a previous feature article (see HPC September 2002, p. 14). Both performance and cost have driven the selection of composite materials and processes for some key parts. One of the biggest challenges, especially in terms of size, is the enormous rear pressure bulkhead, which separates the pressurized cabin from the unpressurized aft fuselage structure.

Airbus has successfully produced carbon fiber composite bulkheads for the smaller A340 model for years, using prepreg and hand layup methods. Comfortable with a composite solution for the A380, which saves at least 40 kg/88 lb over a metallic bulkhead, Airbus wanted to find a way to produce the part more cost-effectively. The company has specified resin film infusion (RFI), and once in production the bulkhead will be the largest manufactured RFI structure.

Infusion methods are gaining share in aerospace applications and the bulkhead's uniform shape and thin profile lend themselves well to the simplicity of RFI, in which a preform is placed over a solid resin film and infused under heat and pressure. By contrast, traditional hand layup of the 6.2m/20.2 ft long, 5.5m/17.9 ft wide and 1.6m/5.2 ft deep bulkhead would have been logistically difficult and labor-intensive. According to an Airbus spokesman, the RFI process "had matured sufficiently" to make the cut for the A380.

Preforming of dry reinforcements key to effective manufacture

RFI garnered a lot of industry attention about five years ago, when The Boeing Co. demonstrated the method's ability to create a complete wing structure as part of a NASA program. The straightforward vacuum-bag molding process uses a dry textile preform tailored to the part's performance requirements. RFI is appropriate for relatively thin parts with simple shapes because the resin film is easily placed on flat or low-curvature molds and, once heated, only has to travel a few millimeters to wet out the preform. Thicker sections with more complex geometry are better suited to other processes like resin transfer molding (RTM).

Infusion methods in general and RFI in particular provide some real benefits, including high fiber volume and low void content as well as more uniform parts. And dry fiber typically is more cost-effective than prepreg material, reducing overall manufacturing cost. The method has been successfully employed for a number of prototype parts, and RFI variants, including SP Systems' (Isle of Wight, U.K.) SPRINT process and Advanced Composites Group Ltd.'s (Heanor, Derbyshire, U.K.) ZPREG method, have recently been introduced for automotive applications.

For Airbus' elliptical dome-shaped pressure bulkhead, the reinforcement is non-crimp stitched 0°/90° biaxial carbon fiber material supplied by SAERTEX USA LLC (Stade, Germany). Fiber is Toho Tenax America Inc.'s (Mishima, Japan) high tensile modulus 6K and 12K carbon. The stitched material is produced in 1.27m/50-inch widths — with the 90° orientation on the bottom, the 0° fibers on the top — on a Liba machine. To obtain the appropriate dimensions for the part, six widths of biaxial material are stitched together, with a 25-mm/1-inch overlap, to form a 7m/23-ft wide, 7.4m/24-ft long "carpet." In turn, six carpets are stacked to make up a single preform for the bulkhead. SAERTEX rolls the preform up from each end until the rolls meet in the middle. The rolled preform is then transferred from SAERTEX's newly constructed facility immediately adjacent to Airbus' Stade fabrication plant, located near Hamburg, Germany.

"The new SAERTEX plant is no more than 50m behind our fence," says Jens Gralfs, responsible for composite technology development at Stade. "It really simplifies the logistics to have a supplier located so close."

Fabrication of the bulkhead takes place on a male mold fabricated from ST52 tooling steel by Airbus' Varel (Germany) facility. "The Varel plant produces most of our tools," says Gralfs. "It's one of our core competencies within Airbus, the ability to produce our own tooling for composite manufacture."

Prior to layup, the tool is prepared with Marbocote mold release supplied by Marbo Italia SpA (Pogliano, Italy). First down on the mold are several HTA 977-2 carbon fiber/epoxy prepreg "doublers" or pre-measured single-ply reinforcements supplied by Cytec Performance Materials Inc. (Tempe, Ariz., U.S.A.). The doublers act to reinforce the attachment areas along the edges of the part as well as the four openings that must be cut in the bulkhead during installation to accommodate hydraulic, electrical and air lines.

CYCOM 977-2, 1,000 gm/m2 resin film, supplied by Cytec in 1m/39-inch wide rolls backed with paper, is then placed over the tool and the doublers. The film, which is a non-tacky solid at room temperature, is cut, positioned and overlapped so that all areas of the tool have adequate resin to wet out the preform. The ability to use a higher-viscosity toughened resin like 977-2 is one of the benefits of RFI, because the resin does not have to flow far to wet out the preform. In contrast, RTM methods generally must employ lower-viscosity resins because of much longer and more tortuous flow paths. "We chose the 977-2 because it's a standard, hot-melt prepreg resin with an extensive historical database for aerospace structures," says Gralfs. An additional advantage of 977-2 is that it is the only epoxy qualified at Airbus for primary structure that also meets European and U.S. flame, smoke and toxicity requirements, which is necessary because one side of the bulkhead faces the passenger cabin, hidden behind a non-pressurized wall panel.

After the film's backing paper is peeled off, the preform is then positioned over the mold with the help of an overhead gantry crane and the laser guidance system. The edges are trimmed, and the part is then vacuum bagged to evacuate the air from the preform. The entire mold is then moved into the autoclave for a normal 977-2 cure cycle of approximately 90 minutes at 177°C/350°F and about 100 psi pressure. Total cure time including ramp-up and ramp-down is about six hours, says Gralfs.

Second processing step required for now

After cure, additional processing is necessary to complete the part. The bulkhead design includes 15 radial stiffeners, 2.5m/8.1 ft long, 80 mm/3.2 inches wide and 40 mm/1.6 inches tall, which are added post-cure. The stiffeners are made with Cytec prepreg (the same material used for the doublers) wrapped around A-profile-shaped Rohacell polymethacrylimide (PMI) foam supplied by Degussa Performance Plastics (Darmstadt, Germany). Degussa's new Shapes group CNC machines the foam stiffeners to the correct dimensions and ships them as a kit in moisture-proof aluminum bags to Airbus.

The foam acts as a "flying tool," according to Gralfs. "To achieve the desired shape of the stiffeners, we use the foam as a tool or mandrel. It doesn't have a structural function and it stays in the part, since we can't remove it," he explains. The foam's resistance to high temperature and creep allows it to undergo the second autoclave cure cycle, which is necessary to cure the stiffeners, while its light weight doesn't affect part performance.

Also added in the second layup step are two plies of Cytec 0°/90° woven E-glass/epoxy prepreg, placed around the bulkhead's rim to protect against any galvanic reaction between the carbon and the aluminum aircraft structure. The entire part is then bagged again and sent to the autoclave for a second cure.

Gralfs justifies the second cure cycle as a risk reduction decision, at least for the first few production parts. "We've done some manufacturing tests, and we know we can do the part in one shot. But the bulkhead is a very critical part with very high quality requirements, so we decided to split the process into two steps, to minimize any problems and stay with the proven," states Gralfs. "It's the optimal process for initial production — we'll continue to work on making it in one step, eventually."

More testing on the horizon

After the second cure is complete, titanium strips are fitted around portions of the perimeter bulkhead flange. Gralfs says that the majority of the load is transferred from the bulkhead to the fuselage and airframe via the strips and titanium fasteners, but there are some direct flange-to-aluminum fasteners as well, which necessitates the glass galvanic corrosion barrier.

An extensive series of tests were conducted on material coupons, to qualify the materials and process. To date, two demonstration article bulkheads have been fabricated to test the actual manufacturing methods. The prototypes have undergone nondestructive ultrasonic testing to assess part quality. In about one year, a full-scale static test will be conducted to verify the bulkhead's ability to withstand limit and ultimate design loads.

Airbus has always maintained that a new material or process has to earn its way onto an airplane, by proving not only its weight-reduction capabilities but also its cost-effectiveness. In this case, the RFI process incorporating a preform makes a huge composite part possible, cutting manufacturing costs by half compared to hand layup.

Related Content

3D weaving capabilities achieve complex shapes, reduce weight and cost

JEC World 2024: Bally Ribbon Mills is displaying film-infused 3D woven joints, woven thermal protection systems (TPS) and woven composite 3D structures.

Read MoreBiteam introduces 3D Noodle International AB spin-off for 3D fabric noodles

Biteam 3D’s third spin-off implements its proprietary 3D weaving technology to produce a variety of carbon, ceramic and other fiber 3D fabric noodle preforms.

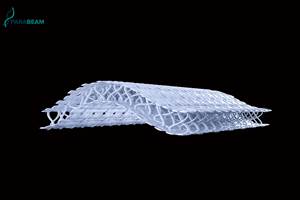

Read MoreCAMX 2022 exhibit preview: Parabeam

Parabeam’s 3D E-glass woven fabrics, particularly ParaGlass and ParaTank, continue to advance composite sandwich structures with high flexibility, strength and application versatility.

Read MorePlant tour: Albany Engineered Composites, Rochester, N.H., U.S.

Efficient, high-quality, well-controlled composites manufacturing at volume is the mantra for this 3D weaving specialist.

Read MoreRead Next

From the CW Archives: The tale of the thermoplastic cryotank

In 2006, guest columnist Bob Hartunian related the story of his efforts two decades prior, while at McDonnell Douglas, to develop a thermoplastic composite crytank for hydrogen storage. He learned a lot of lessons.

Read MoreComposites end markets: Energy (2024)

Composites are used widely in oil/gas, wind and other renewable energy applications. Despite market challenges, growth potential and innovation for composites continue.

Read MoreCW’s 2024 Top Shops survey offers new approach to benchmarking

Respondents that complete the survey by April 30, 2024, have the chance to be recognized as an honoree.

Read More

.jpg;maxWidth=300;quality=90)