Albany International: Multilayer to multidimensional

Albany International (Rochester, N.H.) has a half-century of experience in producing multilayer technical textiles to meet demanding performance and cost expectations.

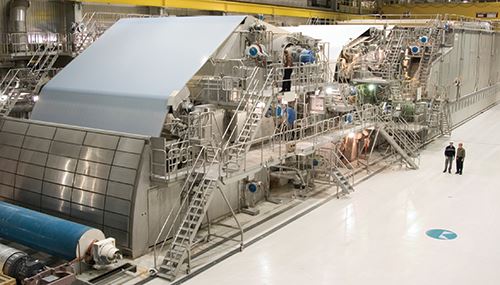

Albany International (Rochester, N.H.) has a half-century of experience in producing multilayer technical textiles to meet demanding performance and cost expectations. The company earned its stripes weaving fabrics used as papermaking machine clothing — the highly engineered, custom-designed fabrics up to 12m/39-ft wide that are essential in multiple stages of paper production.

By the 1980s, multilayer fabrics had become prevalent in Albany’s machine clothing products due to the high tension and shear requirements in papermaking operations, such as calendering through heated rollers. Albany was a key innovator when the Jacquard-type looms used in weaving were transitioned from one-layer to three-layer fabrics to meet this need. For example, it developed the technology necessary to make seams in these massive fabrics with nearly the same strength as the base fabric but without imprinting the seam line onto the paper. Albany also helped pioneer automation of and improved control over the weaving process, including integrated process-data collection, automated fiber handling and error detection.

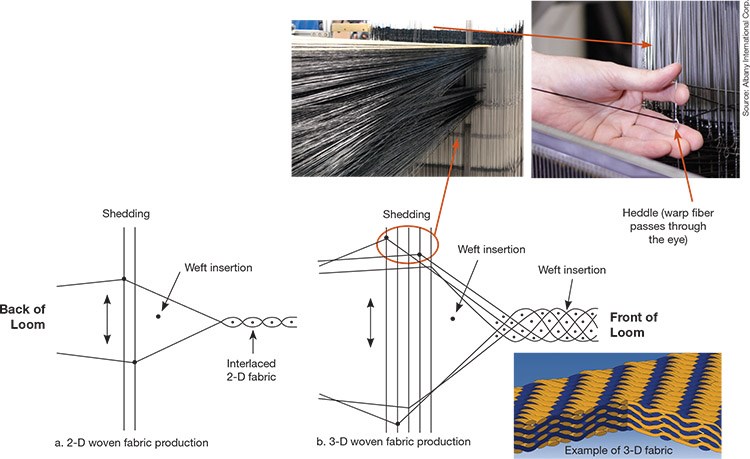

Multilayer fabrics have been woven on traditional 2-D weaving looms for some time. Familiar examples are webbing, belting and, as noted for Albany, papermaking fabric. These fabrics are produced by splitting the warp fibers (oriented in the direction of fabric production) to create multiple sheds (spaces through which the weft or filling fibers are inserted at right angles to the warp). If the warp ends are moved up or down during weaving (in Jacquard looms this is done using heddles, pictured at far right), then the fabric can be made to consist of several layers stacked vertically. Warp ends can be interlaced with fill fibers in the adjacent layer to produce layer-to-layer locked fabrics, or they can be interlaced with fill fibers in the top and bottom layers to create angle-interlocked fabrics.

Albany has established itself as the market leader in the competitive and now mature papermaking fabric market through continued R&D investment. Its subsidiary Albany Engineered Composites (AEC) has, in turn, built on this foundation, using the parent firm’s 50 years’ experience in textile process development to exploit the ability of the Jacquard weaving process to lift each single warp end — there are 8,448 in AEC’s current 3-D looms — either alone or in combinations, to create almost infinite possibilities for warp and weft patterns. AEC, thus, is pursuing the potential for 3-D textile preforms to help reduce the cost of unitized composite structures. AEC’s senior VP of business development, research and technology Brian Coffenberry concludes, “Just like Jacquards are currently used to create intricate patterns on mass-produced ties and carpets, we are using our innovations on this technology to create patterns through the thickness as well as on the surface, tailoring the structural properties of the 3-D composite and final structure.”

This short article is a sidebar to a feature article titled "Albany Engineered Composites: Weaving the Future in 3-D." To read the article, click on its title under "Editor's Picks," at top right).

Read more about 3-D wovens from 2-D looms in the “3-D woven reinforcements update,” under"Editor's Picks."

Related Content

3D weaving capabilities achieve complex shapes, reduce weight and cost

JEC World 2024: Bally Ribbon Mills is displaying film-infused 3D woven joints, woven thermal protection systems (TPS) and woven composite 3D structures.

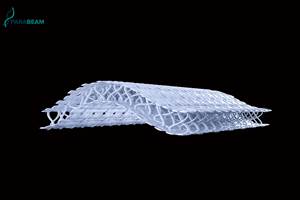

Read MoreCAMX 2022 exhibit preview: Parabeam

Parabeam’s 3D E-glass woven fabrics, particularly ParaGlass and ParaTank, continue to advance composite sandwich structures with high flexibility, strength and application versatility.

Read MoreBraskem demonstrates PP solutions using Weav3D composite lattice technology

Partnership combines Braskem’s polypropylene sheets with Weav3D Rebar for Plastics technology to address new structural, automotive applications requiring high-strength, lightweight material solutions.

Read MoreBiteam introduces 3D Noodle International AB spin-off for 3D fabric noodles

Biteam 3D’s third spin-off implements its proprietary 3D weaving technology to produce a variety of carbon, ceramic and other fiber 3D fabric noodle preforms.

Read MoreRead Next

Albany Engineered Composites: Weaving the Future in 3-D

This 3-D weaver turned composite component supplier pursues a future in 3-D structures through continuous technology development.

Read More3-D woven reinforcements update

Suppliers make progress toward reinforcement preforms that exhibit comparable properties in the x, y and z axes.

Read More